0:00but welcome to another fiber laser

0:02Learning Lab we finished off the last

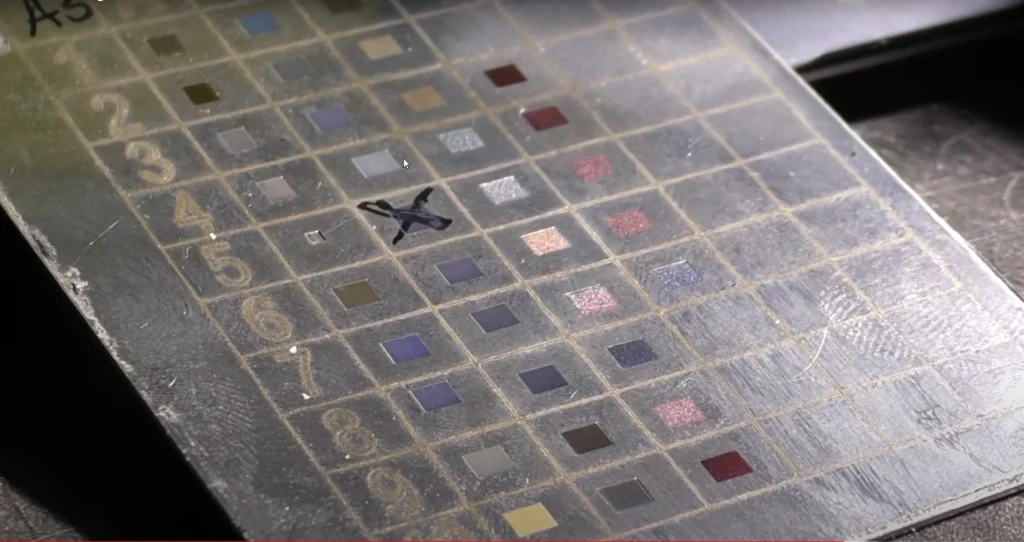

0:05session with a quick sort of scattergun

0:08approach to checking whether or not we

0:11could get any sort of colors on

0:12stainless steel we got these results but

0:16these are an enhanced Photoshop picture

0:20of my photograph and they exaggerate the

0:22colors quite considerably I mean I

0:25looked at all these speeds and

0:26frequencies to see whether or not there

0:29was any pulse rate or on/off ratio that

0:35I could mix together to get some sort of

0:38idea of whether or not I was getting

0:41into the right sort of region to get

0:45between these colors here I mean the

0:47gold and the blue after a lot of time

0:50spent hunting for some magic numbers

0:52everything was common here except the

0:55speed and at a speed of 500 I got gold

0:59and a speed of 200 I got blue ish as I

1:04said this is a gross exaggeration of

1:06reality but it was a bluey hue that I

1:10got so it seemed as though speed was the

1:15magic number now have to also add that

1:19for six nanoseconds which was the

1:22critical factor that I was using I

1:24wasn’t actually using the correct peak

1:26power I should have actually been using

1:28320 kilohertz for peak power so 400

1:32kilohertz means I’m running faster than

1:35I should do so that probably means that

1:36are not allowing all the electrons to be

1:39promoted to their excited state before I

1:42push the pulse through and try and try

1:45and get to peak power so that probably

1:47gives me another way of controlling the

1:49power into each pulse so we’ve got

1:53several strategies that we can adopt I

1:57think the last time we looked at it we

1:59found that this gold one here was

Transcript for The Hunt for Colours – Color Fiber Laser Engraver (Cont…)

2:03actually caused by lines and in the

2:08lines we were finding gold pattern

2:12so what this tends to indicate is that

2:15my little pattern of interference colors

2:17which is you can surf managed to get

2:19them back by using not daylight but the

2:24halogen work lamps as opposed to LED

2:26work lamps have got a wider spectral

2:29range and I can see the real colors in

2:32this light but what this does mean is

2:35that the pattern that you’ve just seen

2:38has caused by a variation in the

2:40thickness of this as we said before T

2:43which is the thickness of the oxide film

2:47now there’s no doubt that the thickness

2:50of the oxide film is the cause of the

2:52colors but but what these tests show is

2:56that because we’ve got lines with colors

2:59in them we must be forming this oxide

3:03layer in a different way than what I’d

3:05originally anticipated

3:06and whereas I thought that we might have

3:10to fiddle around with this surface here

3:12and build the layers up and down I think

3:15that what we’re doing we’re cutting into

3:18the surface and melting the surface so

3:21we could either be melting the surface

3:23and when the surface resolidify x’ we’re

3:27getting this oxide fill on the surface

3:29or we’re vaporizing this area and we’re

3:34leaving an oxide film on the surface

3:36within the groove that’s what it looks

3:39like from the pictures under the

3:40microscope this second situation this

3:43opens up many possibilities first of all

3:46if we’re doing deep grooves like this

3:49we’re into one sort of heating situation

3:52and that is very possible because

3:54remember the beam that we’re firing at

3:58the work although it is only somewhere

Transcript for The Hunt for Colours – Color Fiber Laser Engraver (Cont…)

4:01in the region of about 0.06 five

4:04millimeters diameter it is not 0.065 of

4:09uniform energy the energy distribution

4:12in that beam

4:15is Gaussian in other words we’ve got a

4:17high power right in the center of the

4:20beam and it drops away to nothing

4:22towards the outside so that would

4:24account for why we’ve got a bit of a

4:26groove when we do our burn and why we

4:30see these patterns of speckles which

4:34tend to be along the edge rather than

4:37the center and we tend to get a bit of a

4:39black mark along the center of our line

4:42so observation tells me that we’ve got

4:44lots and lots of strategies to play with

4:47here now as we found out from here there

4:50are rules that govern these colors and

4:53those rules are these very simple

4:55temperatures so what we’ve got to do is

4:59find a way of somehow inducing these

5:03sorts of temperatures into the surface

5:05now if we’re melting then mm that’s a

5:09bit interesting because you remember

5:12that when we heated this surface up in

5:14the middle here to red hot it cooled

5:15down to blue so I don’t know where the

5:19melting I don’t know how melting is

5:21going to give us this yellow color I

5:22suspect we’ve got a very large thermal

5:24gradient away from where the actual beam

5:27is to the very small area around it so

5:33I’ve got this problem of trying to work

5:35out how to keep the heat energy into a

5:39specific area we’ve got to raise the

5:42temperature quite high to get some of

5:44these colors now from some of the colors

5:48that I’ve seen other people achieve

5:50they’re not on this spectrum but I

5:53suspect if we’ve got careful control we

5:55may well have them somewhere in this

5:57spectrum so the first thing I’m going to

5:59do is to see if I can replicate this

Transcript for The Hunt for Colours – Color Fiber Laser Engraver (Cont…)

6:03approximate pattern now as I said it

6:05didn’t go from gold to a lovely pale

6:07blue like this it was quite a reasonable

6:10gold to a blue hue we’re not going to

6:15carry it out in a scattergun approach

6:16we’re going to be in we’re going to

6:18adopt a lot more logical approach and a

6:21recording approach to all the results

6:24and data that are finding

6:26so I’m using my 304 elf stainless steel

6:28and I’m going to be using that grid

6:30pattern and recording the data aha now

6:34what have I done here I’ve got a

6:37temperature measuring system which will

6:40record the maximum temperature that I

6:43see and just here we’ve got a k-type

6:48thermocouple which I’m going to set in

6:52the center of my engraving pattern now

6:57that looks thermocouple bead there are

6:58sitting up above the surface so when I

7:02put my pattern there the thermocouple is

7:09touching under the center of that square

7:12so that means that I will now be able to

7:15record not the surface temperature but I

7:18shall have an idea of the amount of heat

7:22energy that’s going into each one of

7:23these tests by virtue of the conducted

7:27temperature onto the back surface now

7:30the reason I’m doing this is because

7:31it’s not obvious sometimes that when you

7:35change the pulse width the frequency the

7:40speed exactly what you’re doing you have

7:43to sit down and think about it very

7:45carefully because it’s quite a complex

7:47combination of data and then you’ve got

7:49the other thing which is the line width

7:52spacing between the scans and the

7:55pattern of the scans as well so

7:57hopefully with the aid of the

7:58temperature data we may be able to home

Transcript for The Hunt for Colours – Color Fiber Laser Engraver (Cont…)

8:01in on some of these colors because the

8:03colors around the outside the yellows

8:05and the Browns around the outside are

8:08relatively low temperatures and the

8:10Blues in the center are high

8:12temperatures so that would imply that we

8:15need to have a fairly high temperature

8:17in our scan to produce a blue so the

8:22first test that we’re going to do is the

8:24gold to blue test so we’ll jump down

8:28probably in intervals of 20 millimeters

8:33a second to see if we can find a pattern

8:35of change in the color

8:38so we do the first one or two just to

8:41show you the method and what I’m doing

8:42and then after that I would just plot

8:45away on my own and see what I could find

8:48recording the data as I go and then

8:50coming back to you from time to time if

8:53I can find something that’s interesting

9:02I think it’s pretty obvious we’ve gone

9:06from a very very pale gold silvery color

9:08almost through Browns to sort of a

9:13purpley color and eventually down into a

9:17blue it’s not a strong blue you have to

9:20catch in the right light to see as a

9:22blue but that may well be because I’ve

9:25got the line spacing at the moment at

9:27point one

9:28I’ve got gaps between the lines we’ll

9:31repeat this test but with a line spacing

9:34of 0.05 which is just below supposedly

9:38the thickness of the beam spot size even

9:42in this halogen light it’s still not as

9:45good as daylight well if I hold it in

9:47the light right I’ve got a range of

9:50colors there but they’re to be honest

9:52they’re pretty pathetic and weak colors

9:55most of them the golds and the Browns

9:58are fairly positive but it seems as

Transcript for The Hunt for Colours – Color Fiber Laser Engraver (Cont…)

10:01though almost everything comes out gold

10:03or brown so at the moment I’m not

10:05producing huge temperatures you can see

10:08they’re 31 36 38 48 when I get to this

10:13latter set here which was point zero one

10:16in other words the spacing between the

10:18lines was very close so I was over

10:21writing several times the same spot

10:25almost then the temperature started to

10:28go up it was 83 up to 132 and by the

10:33time we finished the test at 200

10:35millimeters a second rocked 199 degrees

10:41C you think Oh 199 I should get a little

10:46bit of color there I’m sure as I fail it

10:49with my fingernail both of these colors

10:52d1 and d2 have suffered surface damage I

10:57can feel a real depth to that cut okay

11:02it’s not very much it might only be

11:03about 0.2 0.3 of a millimeter but

11:06there’s definitely material missing from

11:08the surface now so the only reason

11:10material can be missing from the surface

11:12is because we’ve evaporated it

11:14and if we’ve evaporated we must have put

11:16a very very high surface temperature

11:18into there and in doing so is I suspect

11:21that we’ve gone beyond melting the

11:23surface and just allowing it to reform

11:26we may well have messed around with the

11:27chemistry of the material itself and in

11:31which case that would account for why

11:33these particular colors are more solid

11:37more pigment like than the others I mean

11:40the others are definitely they change

11:43very much with the light now got to be a

11:46little bit careful here because it’s

11:48possible that when we come across these

11:50matte blacks and browns we’re actually

11:53messing with the chemical composition of

11:55the steel itself we’re melting it and

11:58causing some elements to vaporize away

Transcript for The Hunt for Colours – Color Fiber Laser Engraver (Cont…)

12:02and change the chemical composition of

12:04the surface of hence the color I don’t

12:06think that these are representative of

12:08the colors that we’re looking for so we

12:11need to go hunting in a different area

12:13we’ve found the golds and the Browns and

12:15a hint of blue but we haven’t got any

12:18other colors not entirely true if we

12:22take a look at on my grid pattern there

12:25this is the top of the a that I’ve drawn

12:28in and here we can clearly see what I

12:30was speaking about earlier the thin line

12:33down the center where we’ve got maximum

12:35power at the centre of the beam and then

12:37around the edge here we’ve got the lower

12:39power which has given us the yellow or

12:42the Goldy color very distinct Brown a

12:44yellow color this is a 6 no no second

12:47pulse 400 kill Urtz appoint one line

12:52spacing so the line spacing is bigger

12:54than the spot size and it was done at

12:59460 millimeters a second now you can

13:03clearly see there some of the out some

13:05of the things that I’ve described to you

13:07before was I was expecting we’ve got

13:09yellow spots on the side and we’ve got a

13:12black line down the center where maximum

13:16power seems to exist so there’s our

13:19yellow grid line

13:22and here’s what’s supposed to be blue

13:26we’ve got this black line right along

13:29the center again which is the dick cut

13:31right at the center of the beam I don’t

13:34see any blue in there and then we’ve got

13:36these markings on either side which if

13:38anything are a sort of a bit of a hint

13:41of yellow on them still and that’s a

13:45scan at point zero five where the lines

13:49are probably just beginning to overlap

13:52but you could still see the black lines

13:54there which are the center of the beam

13:56the burn line on the beam

13:58so we’re burning into the material so

Transcript for The Hunt for Colours – Color Fiber Laser Engraver (Cont…)

14:00that’s 10 microns spacing and all of a

14:03sudden we’ve lost the center of the

14:05lines because I suspect that what we’re

14:07doing there we’re melting the surface

14:09and it’s just flowing together for the

14:12steel to melt it’s got to be up to

14:13something like about 1,400 degrees C and

14:16we’ve got to burn through the the oxide

14:19layer to start with which has got a

14:21melting point of about 3,000 degrees C

14:23now we’re not seeing anywhere near those

14:26sorts of temperatures projecting through

14:29to the back of a half mil sheet of

14:31material but we are getting up quite

14:33high at 199 degrees C when we do

14:36something like this yeah this is all

14:38interesting stuff but it’s not getting

14:40me pinks and reds and greens got good

14:43yellows good golds they seem easy to get

14:46well here I am in the office at the

14:48moment because it’s a bit cold out in

14:50the workshop and I thought well I’ll

14:51I’ll find an excuse to go inside in the

14:53warm and maybe I’ll edit the material

14:55I’ve done so far it’s sometimes great to

14:59stop and have a bit of a think because

15:01when your brain is running in a straight

15:03line

15:04sometimes it’s got its own momentum and

15:07it can’t stop well this is a natural

15:10break and it gives me an opportunity to

15:12look and review what I’ve found so far

15:15now it’s interesting when I look back

15:18and say this little shape here which is

15:23the cut seems to produce some sparkles

15:28on the side we seem to get color down

15:31the center and as you have watched this

15:32video already you’ll understand what I

15:34me as I move through the video I

15:37mentioned some of the fact that these

15:41colors here and the ones down here which

15:44were done and a much finer resolution

15:47first of all they deeper which means we

15:50have evaporated material will remove

15:52material but we’ve also probably it

15:56looks as though we have destroyed the

15:58surface of the material as well when I

Transcript for The Hunt for Colours – Color Fiber Laser Engraver (Cont…)

16:00get towards the end here and we start

16:02looking at the different line spacing

16:04that I’ve been using for some of these

16:06we find it there’s my point one cut with

16:11the black heavy line down the center but

16:14you can see the live of glittering bits

16:16on the side that are producing some

16:18color my thought was that that color was

16:22being produced on the side by the thin

16:24film effect because obviously we’re not

16:29getting this thin film effect on a flat

16:31surface as I was getting with my oxide

16:34films when I heated the material up with

16:38we might have the same mechanism but

16:40it’s not happening in the same way so

16:42for me to try and copy that thin film on

16:45the surface is not going to give me what

16:48we’re looking for so I’ve got to look

16:50for some other mechanism and I’m finding

16:54the clues here now as I look back

16:55through these results so there we go

16:58look I’ve now moved on to a point O 5

17:01pitch so the lines are so much closer

17:04together that’s supposed to be a sort of

17:08a a bit of a blue and in the right light

17:11it does show up as a pale blue a bit of

17:14a weak pathetic blue but it’s still blue

17:18but then all of us have now change the

17:21that pitch between the lines 2.01 10

17:27microns and I get this weird effect

17:30which looks like a mat you know a piece

17:34of fabric or something

17:36it’s very strangely textured the surface

17:41now that does not look like melting it

17:45doesn’t look like

17:47anything that I can imagine except a

17:50piece of fabric as I sit here I think to

17:53be some fabric my wife loves iridescent

17:58fabrics iridescent butterfly wings

Transcript for The Hunt for Colours – Color Fiber Laser Engraver (Cont…)

18:05scales I remember back to watching some

18:11very interesting scientific programs on

18:13that the color is not coming from the

18:16reflection of two surfaces it’s coming

18:20from maybe two surfaces but a pattern of

18:25surfaces not just a single flat surface

18:29scales peacock feathers butterfly wings

18:34they’re all made up of micro structures

18:37nano structures of material which

18:41reflect the light in different ways so

18:44maybe as I sit here and look at that

18:46picture I’m looking at a clue to how

18:50these colors actually exist so we’ve

18:53gone beyond the possibility of producing

18:54these colors by a thin film interference

18:57pattern from a flat surface to maybe the

19:02same mechanism appearing on earth

19:04geometrically repeating rough surface

19:08okay I’m live on the screen at the

19:10moment let me do a little bit of

19:11googling and see what we can find

19:13interesting you look iridescent it’s

19:17still caused by thin film interference

19:19patterns we’ve got oil on water and

19:22we’ve got soap bubbles and here we look

19:28as though we’ve got butterfly wings or

19:30peacock feathers now I don’t know what

19:32they are

19:32oh there’s a peacock feather but this is

19:35what I’m interested in particularly this

19:37is what I do remember butterfly wings

19:39and over here look we’ve got this

19:40pattern which is a repeating pattern

19:44that causes iridescent it’s reflections

19:50off of repeating surfaces so we’ve got

19:54not only one destructive or constructive

19:59and

Transcript for The Hunt for Colours – Color Fiber Laser Engraver (Cont…)

20:00reflection we’ve got lots and lots of

20:02them mixed together so here we’ve got

20:06some interesting data this looks to be a

20:10a scale of about on this basis ten

20:14microns point zero one which is exactly

20:18the area where I’m working at at the

20:20moment with that yellow gold pattern

20:22that all of a sudden appeared I’m trying

20:25to get an idea now of what sort of

20:29surface we require to produce this

20:32effect because we’ve got a machine here

20:34which is capable of producing some very

20:36accurate and repeatable patterns on the

20:39surface the real answer to how we can

20:41get colors they’ll still be iridescent

20:44and changing colors but they will be

20:47more solid than the strange colors that

20:49I’ve been able to get so far so there’s

20:54even a bit of a description here about

20:55how we’re able to get color from our

20:58little V grooves it’s no longer a matter

21:02of reflection off of a shiny top surface

21:05but how can we produce a structured

21:09surface to reflect the light in the same

21:11way that these feathers and these

21:14butterfly wings do right let’s get to it

21:17so I’ve gone for some extremes we do do

21:19we’re going to do a speed of 2000 pulse

21:22of 2 nanoseconds 850 kilohertz and a

21:26pitch of 1 micron very very fine pitch

21:38speckled but it’s gold one of those easy

21:41colors to find two thousand millimeters

21:45a second means I’m actually spacing the

21:48dots out quite a lot so although they

21:50are tight

21:52this way I’m spreading them out that way

21:55here I’ve got my calculation my pulse

21:58rate chart which tells me to stand speed

Transcript for The Hunt for Colours – Color Fiber Laser Engraver (Cont…)

22:01against the number of pulses per minute

22:04the pulses per millimeter holster I’ve

22:06got the scan set to 1 micron which is a

22:08thousand increments per millimeter or a

22:11thousand scans per millimeter so I did a

22:18quick test at a thousand scans in the

22:21other direction as well which is 800

22:23speed and that got me from gold to

22:28copper so maybe let’s go right to the

22:32other extreme and go down to something

22:34like about 300 so now I’m doing nearly

22:373,000 pulses per millimeter across so

22:42now thought you’re so very brave you

22:43certainly didn’t want to sit around and

22:45watch me doing all this stuff but hey

22:47look at see one there that’s a sort of

22:51olive green with a blue and a pink and a

22:59dark magenta gold blues pinks for a

23:04change I’m hand holding the camera

23:05because I need to pan around this

23:08picture we’re looking at it in

23:10artificial light I want you to watch

23:12these colors here and I want to watch

23:14these Pink’s here these blues as I move

23:21around them

23:25or changing

23:32but the Pink’s are not and some of the

23:36other colors are not changing well it

23:43means there’s a definite difference in

23:45the surface texture of the material I

23:49think we’re getting somewhere

23:52now I have just remembered a very very

23:55old friend I’m gonna have to go crawling

23:59around in my loft space and see if I can

Transcript for The Hunt for Colours – Color Fiber Laser Engraver (Cont…)

24:03find it look at this rust dust this is a

24:15piece of junk that I recovered from the

24:18scrap bin of a company that I work for

24:21in Southern Ireland it’s a big American

24:25company and they use these on their

24:28production line and when something went

24:29wrong with them they literally just used

24:31to unclip them and throw them in the bin

24:36when the spillage was full it would be

24:38given to the scrap man well I recovered

24:40several of them from the scrap bin and

24:42made this Franken microscope and then I

24:45built my own base this was 40 years ago

24:49remember 1980 I thought it was too good

24:52to throw out at the time because the

24:54kids would make use of it looking for

24:55looking at bugs and various other things

24:57mmm they weren’t particularly interested

24:59in it so it’s that up in the loft for

25:01years and years and years hey whoever

25:05thought that I would be recalling the

25:08services of this good old friend even a

25:11silly little like work they didn’t have

25:13LEDs in those days this is just a

25:16filament lamp now the interesting

25:18difference between these colors and the

25:20ones that I’d been finding previously

25:22most of these colors do not change as

25:25you put the light in two different

25:27directions whatever is happening now is

25:29definitely on the surface of this

25:30material I’m hopeful that because this

25:32is a stereomicroscope I will be able to

25:34see exactly what the difference is

25:37between some of these surface textures

25:39are

25:40oh it’s not an LED so that light

25:43actually gets hot now the problem with

25:45this wonderful microscope is you can’t

25:47see what I can see I can only give you a

25:50little clue as to what I can see if you

25:53take a look at the corner of that D

25:55there that’s just about what I can see

25:58in the microscope that just gives you an

26:00idea of the magnification that I’ve got

Transcript for The Hunt for Colours – Color Fiber Laser Engraver (Cont…)

26:02it’s not a huge magnification it’s

26:04probably only about somewhere between 40

26:06maybe 60 at the most magnification now

26:10this might not be very exciting video

26:12for you but all I can say is Wow and now

26:18I’m going to take a look at one of the

26:20colors looking at the dark red mark

26:22we’ve just got a few sparkly stars in

26:26the sky just a few with some green ones

26:29when I moved to this one which is the

26:32slightly lighter movi pink all I can say

26:37is look this is my white phone cover

26:39that’s what I’m seeing now I’m afraid I

26:42don’t have an electron scanning

26:43microscope in my workshop that allows me

26:46to examine the surface of this in great

26:47detail this stone age technology is

26:51about as close as I can get at the

26:53moment but what we can do is to try and

26:56upgrade this with the aid of an HD

26:59camera so that you can see what I can

27:03see but at 40 maybe 60 at the most

27:07magnifications with this lovely piece of

27:10kit it’s not enough for me to see the

27:13granular structure right on the surface

27:15of the material where the damage is

27:16taking place now this looks like at the

27:20moment a crystalline structure but I

27:24have got a little toy a plastic toy

27:26microscope which I’ve also used which I

27:32won’t even show you because I’m

27:33embarrassed about it but it does show me

27:35that maybe there’s a different picture

27:38to the one I’m seeing here with this

27:41device at the moment I’m seeing what

27:43looks like a crystal type

27:45reflection but it might not be that when

27:48we get down and have a real look at the

27:49surface and to do that I’m gonna have to

27:51purchase a proper compound microscope

27:53that allows me to get to anything maybe

27:56between 200 400 600 or even a thousand

28:00times magnification so that we can

Transcript for The Hunt for Colours – Color Fiber Laser Engraver (Cont…)

28:02really examine the surface and work out

28:04what damage this beam of light that

28:08we’re able to control is doing to the

28:11surface so we’ll stop there for today

28:13now thank you for your time and we’ll

28:16catch up with you in a future session

28:18when we suitably kitted up to reveal the

28:20secrets of this surface