The toolKaiser App For Digitizing Your Entire Tool Box

If you’re like me, you probably have a multitude of tools spread across dozens of locations and spend almost as much time finding the right tool as using it. You will have looked on in envy at those adverts for tool boxes with precision foam inserts for individual tools. A place for all tools, and all tools in their place. Now you too can learn how to laser cut foam tool inserts for tool boxes like the professionals, but at a fraction of the cost.

I came across the toolKaiser app when browsing through Reddit and I realised it was a tool that could save so many laser users so much time making up tool foam inserts. I remembered selling a laser machine to one customer, where the main application was just making up large sheet inserts and this would have saved them so much time.

But here’s toolKaiser’s story:

The toolKaiser App

A friend of mine is an avid biker and loves to build things. Needless to say, he has hundreds of tools which help him build and fix things. We were talking one day, in the beginning of 2020, about how it would be nice to organize the tools using foam inserts so he knows exactly where his tools are. But manually tracing hundreds of outlines and cutting them out with an Exacto knife felt like a daunting task. Also, the end result of manual cutting doesn’t look quite professional and then there is always the fear of losing a finger :-).

There is also the question of how much foam sheets would you need? Looking around, I quickly realized that nobody offered a solution which wouldn’t require me to send them my tools or they would send a graph paper for outlines to be traced. The turnaround time was always 4-5 weeks or more and would make a sizable hole in my pocket. Since both of us had a tech background, we believed that with modern smartphones, it should be possible to get the outlines of the tools using the smartphone camera and then export them in a laser-cutter friendly format and get professional-looking tool foam inserts in a matter of minutes.

So What Did You do?

So, we decided to build the underlying technology — (1) an app to quickly take pictures of your tools to obtain their outlines, and (2) an editor to refine them and create beautiful layouts. Finally, export the layout in SVG/DXF formats so that the tool foam inserts can be cut by a laser. See the picture below for a visual tour of the product from start to finish.

I rolled out a first version of the product in October 2020 and started to get valuable user feedback from Reddit and other forums and also from actual customers. This helped me to add more features to the app and the editor driven by the needs of the customer. E.g., we started out with only tool foam inserts for rectangular drawers.

What Additional Features Does The App Have?

We soon realized that more and more customers wanted inserts for their Milwaukee and DeWalt tool cases which come in various shapes not necessarily rectangular. We quickly added such a ‘custom toolbox’ feature to our editor.

One of the features that our users liked a lot is the ‘detailed editor’ feature — double clicking on a tool opens a detailed editor which allows you to refine the tool outlines (no picture is perfect and there might be some errors in the traces) by adding, removing and moving the points around. What helps the user in this is that we overlay the outline on the image of the tool. This allows the user to ‘see’ the actual tool and quickly refine & smoothen their outlines.

Is The App Easy to Use?

Another user had a lot of tools and the outlines were imported and placed randomly on the canvas. The user wanted to have a good starting point to start creating their layout. To that end, we enabled our editor to automatically recognize the type of the tool, group all tools of the same type together and run a ‘nesting’ algorithm to compactly layout all the tools. The result was that all tools were nicely placed on the canvas immediately after importing from the app and the user had to do minimal work to get the desired layout.

Another interesting case was when a user took pictures of their sockets, they never got perfect circles. To solve this, we added a feature that quickly converts ‘almost’ circles to perfect circles. Going one step further, we added an exhaustive library of sockets. So, no need to take pictures of your sockets, just add them from our library.

What foam panels were you using for the inserts?

When I was cutting, I was using the 4lb Closed-cell Polyethylene foams, which I used to order in bulk from Cascade. I used to order their Value Plus foams which were 5S complaint (protection from oils, lubricants, etc.). It was a fantastic place to buy in bulk for relatively low costs. They also have pressure sensitive adhesive backing which I used for the 1/2″ foams to slap on the 1/4″ back foam for shadowing.

What Are You Hoping to Achieve?

Our vision is to radically simplify the tool organization process and also make it possible to have highly customizable layouts. In fact, the technology can be used for creating foam inserts not just for tools but for a variety of other objects such as kitchen utensils, watches, etc. We’ve strived to make the technology really simple and also provide in-app feedback and training videos plus FAQs for using the editor. I believe tool organization should be hassle free and inexpensive. Our product makes tool organization fun and easy without sacrificing on the accuracy of the foam inserts.

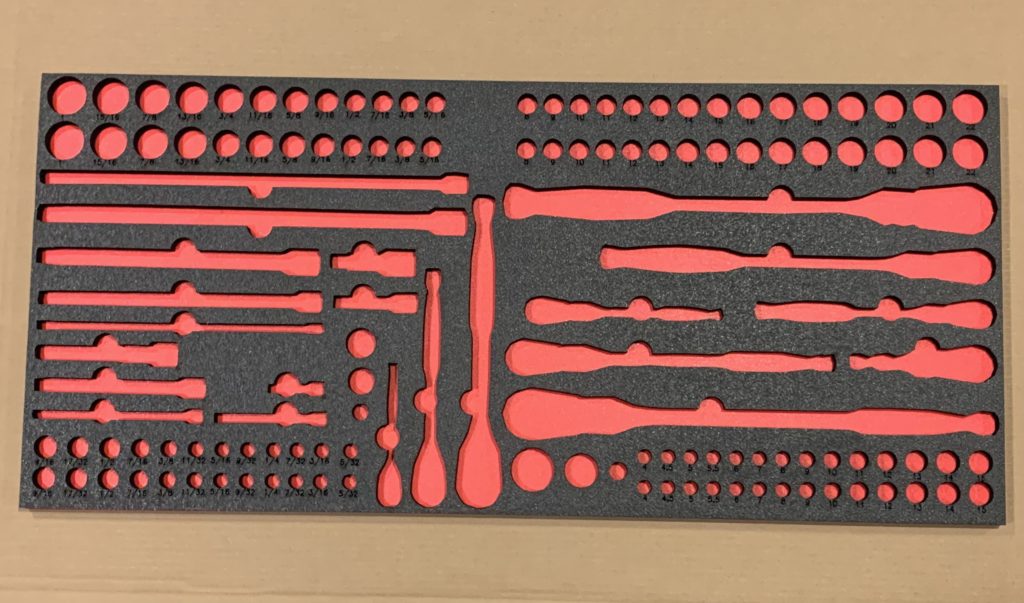

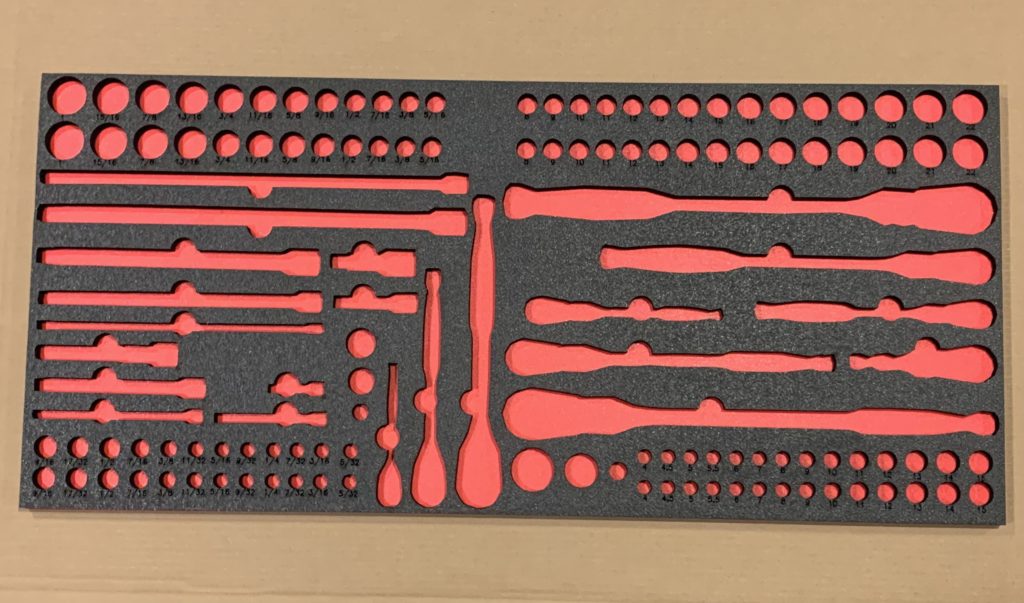

For my first customer, I used Gorilla glue to stick ½” blue foam on a ¼” red foam for shadow effect. I glued several foams in my garage this way :-). Later on, I started using foams with pressure sensitive adhesive (PSA) backing to stick the back foam and also to create foam inserts of multiple depths for thicker tools. The pictures of our first happy customer are just below.

I paired up with a laser-cutting vendor to satisfy customer orders. This also helped me to get valuable feedback on what the users liked and didn’t like. After 8 months or so, in June 2021, I’ve decided to stop the cutting service since I cannot keep up the business all by myself. I’ve made the technology freely available to anyone who can cut the foam inserts themselves. The links for the app and the editor are given below. Please find attached some pictures sent by our happy customers (more pictures on our website ‘Gallery’).

What Foam Can Be Laser Cut?

Care should be taken when attempting to laser cut foams as there are foams that give off highly toxic / corrosive fumes when burnt. However, there are some foams that can be laser cut, and they are usually made up of either Polyester (PES), Polyethylene (PE) or Polyurethane (PUR).

Always try and get the technical specifications of the foam before you start laser cutting and check out the Plastics section at What Can A Laser Cutter Cut for guidance on what to avoid.

ZOTEFOAMS is a global supplier of foams and manufacturers the popular Plastazote® Polyethylene foams, but stay clear of their Zotek® F brand as it contains fluorine. I actually purchased my 30mm thick red/black PE Foam from BigDug in the UK.

Check out our post on How to Laser Cut Foam for more details on the process and settings on how to Laser Cut Foam Inserts.

Other Applications

When I first saw the toolKaiser application, my first thoughts were not related to tool storage. They were related to the safe storage of collections. Items such as geological samples, archaeological and ethnographic objects that may be stored by museums and similar institutions. Each item could be photographed, and have it’s own bespoke storage insert tailored to the storage unit being used. The nesting feature of the software would also ensure efficient utilisation of space, without compromising object security.

Another application I can see this being used for is tool boards. This is where tools are attached to a board on a wall. with an outline of the tool marked onto the surface for easy replacement after use. The app would be used exactly the same way, but the laser would only engrave onto the surface of the board instead of cutting. Adding holes for the placement of fixings would take only moments.

Check out our article on what can a laser cutter cut for information on laser safe materials.

Recommendations On Using The App

Like most activities, “rubbish in = rubbish out“, it is well worth setting up a well lit area and use a tripod or similar to hold your mobile phone in the optimum position to take the photograph. Most smart phones these days have a delay timer, using it will allow you to take the photo without the risk that the act of touching the phone affects the picture. Once set up, taking photos will be quick and easy.

That’s not to say, you can’t take a rough and ready photo and edit it later if it isn’t quite to the standard you wanted.

The app is being made available for free on both the Apple Store and Google Play. So it’s well worth trying it out and see if it does the job for you.

The Important Links

Website: https://www.toolkaiser.com/

Apple store app: https://apps.apple.com/us/app/id1528414619

Google play app: https://play.google.com/store/apps/details?id=com.toolkaiser.toolkaiserapp

Editor: https://toolkaiser.herokuapp.com/

Facebook: https://www.facebook.com/toolkaiser

US Resource for Foam and Foam Cutting Services

Some of the photos used in this post were kindly supplied by Dave at Country Cutter who are based South West of Kansas City. If you are looking for foam stock or laser cutting services, you can contact Dave by emailing here.

Laser Cut Foam Inserts – Eye Candy

What Next?

Did you enjoy this post? Why not check out some of our other posts:

Disclaimer

Last updated August 26, 2021

WEBSITE DISCLAIMER

The information provided by n-Deavor Limited, trading as Laseruser.com (“we,” “us” , or “our”) on (the “Site”) is for general informational purposes only. All information on the Site is provided in good faith, however we make no representation or warranty of any kind, express or implied, regarding the accuracy, adequacy, validity, reliability, availability or completeness of any information on the Site.

UNDER NO CIRCUMSTANCE SHALL WE HAVE ANY LIABILITY TO YOU FOR ANY LOSS OR DAMAGE OF ANY KIND INCURRED AS A RESULT OF THE USE OF THE SITE OR RELIANCE ON ANY INFORMATION PROVIDED ON THE SITE. YOUR USE OF THE SITE AND YOUR RELIANCE ON ANY INFORMATION ON THE SITE IS SOLELY AT YOUR OWN RISK.

EXTERNAL LINKS DISCLAIMER

The Site may contain (or you may be sent through the Site) links to other websites or content belonging to or originating from third parties or links to websites and features in banners or other advertising. Such external links are not investigated, monitored, or checked for accuracy, adequacy, validity, reliability, availability or completeness by us.

WE DO NOT WARRANT, ENDORSE, GUARANTEE, OR ASSUME RESPONSIBILITY FOR THE ACCURACY OR RELIABILITY OF ANY INFORMATION OFFERED BY THIRD-PARTY WEBSITES LINKED THROUGH THE SITE OR ANY WEBSITE OR FEATURE LINKED IN ANY BANNER OR OTHER ADVERTISING.

WE WILL NOT BE A PARTY TO OR IN ANY WAY BE RESPONSIBLE FOR MONITORING ANY TRANSACTION BETWEEN YOU AND THIRD-PARTY PROVIDERS OF PRODUCTS OR SERVICES.

AFFILIATES DISCLAIMER

The Site may contain links to affiliate websites, and we receive an affiliate commission for any purchases made by you on the affiliate website using such links. Our affiliates include the following:

- makeCNC who provide Downloadable Patterns, Software, Hardware and other content for Laser Cutters, CNC Routers, Plasma, WaterJets, CNC Milling Machines, and other Robotic Tools. They also provide Pattern Files in PDF format for Scroll Saw Users. They are known for their Friendly and Efficient Customer Service and have a comprehensive back catalogue as well as continually providing New Patterns and Content.

- Cloudray Laser: a world-leading laser parts and solutions provider, has established a whole series of laser product lines, range from CO2 engraving & cutting machine parts, fiber cutting machine parts and laser marking machine parts.