Or How to Align a Laser Beam

This special RDWorks Learning Lab Video takes you step by step through the stages of how to align a laser beam.

Contents

I recall the uncertainty I felt the first time I removed a mirror 7 years ago. Would the machine ever work correctly again?

Over an 18 month period I kept purposely upsetting my laser beam alignment in an attempt to understand the logic behind setting the beam perfectly and soon discovered that Chinese machine designers either didn’t understand the process or purposely made it difficult for “non-professionals”.

I suspect my first assumption is correct and naïve machine design is responsible for the MANY different laser beam alignment procedures people have proposed to overcome the mess Chinese designers have created.

This session deconstructs laser beam alignment and machine design. I have modified my machines to make beam setting simple with a series of logical and progressive actions that guarantee setting perfection. I have tackled this subject several times over the years but never in such all -encompassing detail.

As a young design engineer I was taught that “you must understand the problem before trying to design a solution”. It seems that very few people really understand what they are trying to achieve with a laser beam alignment guide beyond making sure the beam passes through the nozzle.

Russ Sadler, July 2022

Video Resource Files for the How to Align a Laser Beam

There are no more resource files associated with this video.

External Resource Links for How to Align a Laser Beam

There are no more external resource links associated with this video.

Transcript for How to Align a Laser Beam

Click the “Show More” button to reveal the transcript, and use your browsers Find function to search for specific sections of interest.

1

00:00:00,840 –> 00:00:08,280

Welcome to another article explaining that. Today I’m going to tackle a subject which I’ve played with several times before.

2

00:00:08,940 –> 00:00:19,170

I’ve seen so much. I’m going to be rude and say crap about how to set the beam up on one of these laser machines.

3

00:00:20,220 –> 00:00:29,820

Now, this session will finish up teaching exactly how to set a beam up, why you have to say it that way.

4

00:00:30,240 –> 00:00:35,310

And it’s a complete explanation. So you can choose to ignore if you wish,

5

00:00:35,670 –> 00:00:41,570

and just fiddle with the bits and pieces of screws forever and ever and ever and never get your machine set properly.

6

00:00:41,580 –> 00:00:46,980

So I’m going to show you how you must go about this task and why you have to go about it in a certain way.

7

00:00:47,820 –> 00:00:53,460

But before we do that, I’m going to create something that I’m going to call a beam simulator.

8

00:00:54,060 –> 00:01:02,550

It’s basically a dummy machine that allows me to show you in great detail how to set the beam up.

9

00:01:03,180 –> 00:01:08,430

So the first part of this video is all about creating that beam simulator.

10

00:01:08,760 –> 00:01:13,830

Now, if you don’t want to create a beam simulator for yourself, then just jump to halfway through.

11

00:01:14,550 –> 00:01:24,960

But if you’re interested in making something similar for yourself, the drawings will be available on the art on the WW R&D Works Lab Dotcom website.

12

00:01:25,290 –> 00:01:32,820

In this session, we’re going to take a look at a problem that somebody asked for my cooperation with a couple of weeks ago.

13

00:01:33,400 –> 00:01:45,180

They were trying to design a very simple beam simulation system that would enable teaching laser beam alignment without going anywhere near a machine.

14

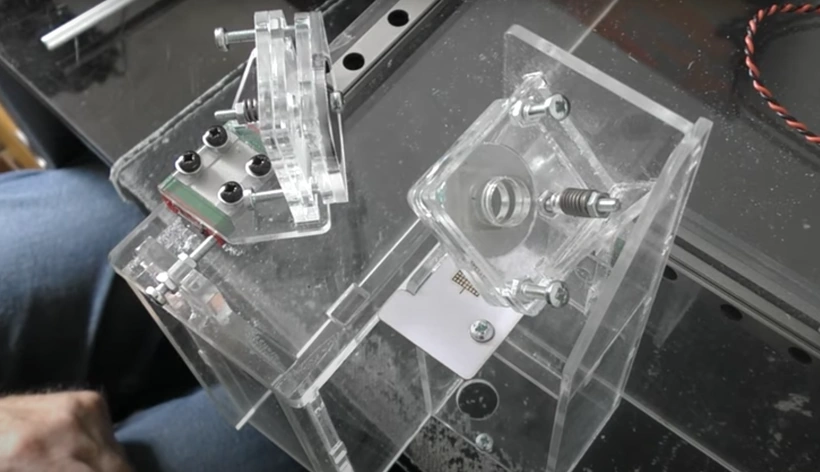

00:01:46,110 –> 00:01:52,590

We’ve got a laser beam, I turn it off and on. And the idea that my correspondent had was a very simple idea.

15

00:01:52,920 –> 00:01:57,780

Basically, he wanted to make something out of chewing gum and string. Okay, so I exaggerate slightly.

16

00:01:58,110 –> 00:02:03,900

That would enable him to very cheaply show how to set a laser beam.

Transcript for How to Align a CO2 Laser Beam (Cont…)

17

00:02:04,260 –> 00:02:13,710

And this is the basic principle that he was working on. And so I took it through to its conclusion to see just how far and how good it could be.

18

00:02:14,240 –> 00:02:23,490

Look, the idea is you’ve got a mirror at position mirror two at position one and mirror to that position, too.

19

00:02:23,850 –> 00:02:31,500

So, hey, we’ve got a pretty good simulation there of the Y axis movement and we should be able to set up the Y axis using this kit.

20

00:02:32,130 –> 00:02:38,370

And then in addition to that, once we’ve set up the Y axis, provided, we turn this kit around and hang it off the edge of the table.

21

00:02:39,180 –> 00:02:44,640

Look, we’ve got a half which we can plug in here as well.

22

00:02:45,570 –> 00:02:53,550

So we can simulate being close to mirror number two or distance from mirror number two, and we can set up the z-axis.

23

00:02:53,670 –> 00:02:59,910

When I first saw the design, I thought, well, the design is simple, but I could see all sorts of problems with it.

24

00:03:00,240 –> 00:03:10,020

So immediately I started working on this design. I ordered a couple of linear rails from China because I felt that the only way to simulate proper

25

00:03:10,020 –> 00:03:17,280

beam settings was to use linear rails because of the stability that’s required by stability.

26

00:03:17,400 –> 00:03:19,049

Let me just show you now.

27

00:03:19,050 –> 00:03:26,400

I think you should be able to see the beam in there, but because it’s got half a millimeter of clearance on it, it’s got a diagonal twist motion.

28

00:03:27,090 –> 00:03:32,850

And look, look, what the twist motion is doing is very difficult to get this thing stable.

29

00:03:33,210 –> 00:03:35,240

And of course, then in addition to that, look,

30

00:03:35,250 –> 00:03:41,070

you’ve only got a little bit of pressure on here and things start moving in this direction is difficult to set it.

31

00:03:41,730 –> 00:03:48,060

So you have to physically hold the thing down like this to make it stable.

32

00:03:51,240 –> 00:04:00,780

So that you can adjust to be. And then when we go and send a beam through mirror one, if we take a look what’s happening on mirror two.

Transcript for How to Align a Laser Beam (Cont…)

33

00:04:00,780 –> 00:04:06,600

Now, if I adjust the laser beam and now look what happens when I just mirror one.

34

00:04:07,800 –> 00:04:12,390

So twisting mirror one, this whole thing is totally unstable.

35

00:04:12,630 –> 00:04:18,460

There’s no way that you can ever set the be into a fixed position and be confident that it’s there.

36

00:04:18,750 –> 00:04:25,710

And of course, it gets even worse when you try and send a reflection off with mirror to when it’s at its extremity.

37

00:04:26,670 –> 00:04:32,340

This is not a full simulation of a machine because we have got no gantry moving backwards and forwards.

38

00:04:33,000 –> 00:04:40,680

Okay. But we’ve got enough of a machine here to simulate setting up the path perfectly.

39

00:04:42,030 –> 00:04:49,920

But we’re going to do it with this fitted kit. The only thing that was successful about this was this bit here.

40

00:04:51,000 –> 00:04:57,570

The laser beam itself. Every sort of laser pointer that you get has got a big beam on it.

41

00:04:57,870 –> 00:05:02,070

Yes, you can generally focus the beam down to a small point.

42

00:05:02,850 –> 00:05:05,610

But you know what happens when you focus the beam down to a small point?

43

00:05:05,610 –> 00:05:12,360

You’ve produced a conical beam, which means that the beam will be big at mirror number one,

44

00:05:13,590 –> 00:05:18,360

get smaller at mirror number two, and eventually it would be a pinpoint down at the work.

45

00:05:18,780 –> 00:05:23,940

That makes it very difficult to set mirrors one, two and three up because you haven’t got a small beam.

46

00:05:24,150 –> 00:05:27,960

This very, very cheap diode laser that I’ve got in here.

47

00:05:28,620 –> 00:05:33,690

It’s not very powerful. Look, it runs off a little battery pack like all laser beams.

48

00:05:34,440 –> 00:05:37,890

It has got a Gaussian intensity distribution.

49

00:05:39,030 –> 00:05:46,050

And what does that mean? That means that right at the center of the laser beam, we have maximum intensity.

50

00:05:46,380 –> 00:05:54,390

And so consequently, we can mask the laser beam and hide it behind a very small hole.

51

00:05:55,380 –> 00:06:05,370

And that very small hole means that we’ve got look, a little matching pinprick, pinprick size, very, very visible laser beam.

Transcript for How to Align a Laser Beam (Cont…)

52

00:06:06,330 –> 00:06:14,400

And as I move it further away, I’m now something in the region of about two feet away.

53

00:06:15,960 –> 00:06:24,300

It hasn’t changed at all. That’s how you can exploit the intensity profile of a diode laser.

54

00:06:24,660 –> 00:06:27,600

Just used the very intense central part of the beam.

55

00:06:27,750 –> 00:06:34,050

Now, after my first attempt, here we are with my pieces, my linear rails that have arrived from China.

56

00:06:34,500 –> 00:06:38,430

And I started to redesign this dummy machine.

57

00:06:38,550 –> 00:06:43,710

And you can see that it’s now a piece of 3D equipment rather than a flat sheet,

58

00:06:44,400 –> 00:06:49,500

and that’s necessary to give us total stability, everything nice and solid.

59

00:06:49,800 –> 00:07:03,630

So I’ve manufactured this strange shaped box out of five millimeter acrylic, and I’ve mounted my two linear x and y rails on here.

60

00:07:03,870 –> 00:07:11,399

So this is going to be wonderful. I can tell you that before I start now, I haven’t designed all the other pieces for this yet.

61

00:07:11,400 –> 00:07:15,630

I’ve had to design them little by little and gradually work my way round the system.

62

00:07:15,810 –> 00:07:19,709

So look, even as we go, I’ve discovered I’ve got to make a few small design changes.

63

00:07:19,710 –> 00:07:24,110

I’ve got a screw that’s going to fix through there, and I don’t want the nuts to twist because they’re underneath.

64

00:07:24,120 –> 00:07:29,400

So what I’ve got to do is to put a little nut play underneath there to stop the nuts from twisting.

65

00:07:30,300 –> 00:07:33,390

I’ve got another piece to go on the back there, but I won’t put it on for a minute.

66

00:07:33,510 –> 00:07:38,669

You see what I mean? I want a guide for this thing to slide backwards and forwards.

67

00:07:38,670 –> 00:07:44,970

What I really should have done has allowed these two tanks here to stand up an eighth of an each project through an eighth of an inch.

68

00:07:45,300 –> 00:07:50,570

And then I had my guide in there for free. Now, I didn’t show you how to assemble the main box up,

69

00:07:50,700 –> 00:07:56,550

because once you’ve got the pieces in your hand, you it’ll become obvious how the pieces fit together.

70

00:07:56,910 –> 00:08:01,680

The next set of pieces are slightly more complex, so I will go through the assembly of these with you.

Transcript for How to Align a Laser Beam (Cont…)

71

00:08:03,450 –> 00:08:11,880

If you note with these pieces with their long legs on, two of them have got hexagons in them and two of them have got holes in them.

72

00:08:12,540 –> 00:08:19,230

Well, what we’re going to do, we’re going to put the put the hexagon in front of the holes.

73

00:08:19,560 –> 00:08:28,170

So we want one of each plate. And on the right hand side, you’re going to have the two square holes.

74

00:08:28,390 –> 00:08:37,530

And they were going to pick up this funny piece here. I made a popper in the back and that plugs through both of those plates like that.

75

00:08:41,410 –> 00:08:49,040

And then we’ve got this one, which is exactly the same hexagon holes in front of the round holes and then you can pop that into.

76

00:08:50,710 –> 00:08:55,250

Yeah, I’m using my favorite PTG crew, which is also an acrylic cement.

77

00:08:55,900 –> 00:09:01,690

But because it runs, because it’s designed for PTG, it goes off slower.

78

00:09:02,050 –> 00:09:09,580

It doesn’t cure quite as quickly. And that’s great because it means you don’t get any cracking along the edges when you glue them.

79

00:09:10,060 –> 00:09:17,530

Whereas with normal acrylic cement, quite often you get stress cracks along the joints and I’m going to pop some glue.

80

00:09:20,020 –> 00:09:26,220

Damn these tongues. And along the back edge.

81

00:09:29,010 –> 00:09:33,880

Then these tongues. And on the back edge.

82

00:09:34,780 –> 00:09:37,390

Now you’ll see that it’s come through.

83

00:09:37,840 –> 00:09:46,959

So if we move it around just a little bit for a few seconds, then the excess glue on the underneath is not there.

84

00:09:46,960 –> 00:09:53,770

It’s dried. I’m also going to put a blob of glue down these bracket supports.

85

00:09:54,850 –> 00:10:00,610

Now, I’m also going to run a bit of glue across the top joint here because I don’t want these plates to come apart.

Transcript for How to Align a Laser Beam (Cont…)

86

00:10:00,940 –> 00:10:06,490

There is a possibility that I might have got something wrong when I calculated the height of this.

87

00:10:06,640 –> 00:10:15,880

This is made of ten millimeters thick material to take into account the fact that this bearing plate is ten millimeters thick, ten millimeters tall.

88

00:10:16,450 –> 00:10:19,490

And I want everything to line up ten millimeters off the deck.

89

00:10:19,510 –> 00:10:26,980

But when I look at this, I think I’ve made a small error in when I put my mirror on here,

90

00:10:27,820 –> 00:10:35,230

it’s probably going to be three millimeters too low because I’ve got an additional plate on there, which is used to fix to the bearing plate.

91

00:10:35,710 –> 00:10:40,810

So I may well have to add another three millimeter matching plate to the bottom of this.

92

00:10:40,960 –> 00:10:47,380

We’re just use a really 20 millimeter type screw package and we’ve got an 83 nut which

93

00:10:47,380 –> 00:10:52,420

will pull back into the hexagon housing and we do the same at the bottom there.

94

00:10:53,230 –> 00:10:56,230

Now, this is for mirror number one.

95

00:10:56,560 –> 00:11:03,490

This is typical for number one, two and three mirror holders themselves, not the frames,

96

00:11:03,490 –> 00:11:08,200

but the actual things that hold the mirrors and make it assemble them like that.

97

00:11:09,460 –> 00:11:16,990

We’ve got a 35 millimeter em three screw with a cross head, pan head will poke that through there.

98

00:11:19,400 –> 00:11:26,390

They’re going to put an m three nut on the back and the entry nut will disappear inside the hexagon.

99

00:11:27,890 –> 00:11:33,470

On the backplate just tighten up the screws. So the nut is actually only jamming the screw on the front plate.

100

00:11:33,710 –> 00:11:36,830

When you put the backplate on, it actually locates on the nut.

101

00:11:37,370 –> 00:11:42,169

So we need to make sure that when you tighten it, tighten up nice and square,

102

00:11:42,170 –> 00:11:48,500

and even so hold it by this back bottom corner by the screw, and then we’ll put some glue.

103

00:11:50,930 –> 00:11:57,620

In two or three places around there. And that would by capillary action, that would migrate between the plates.

104

00:11:59,000 –> 00:12:03,710

And then we can push the plates together and we’ll do this.

Transcript for How to Align a Laser Beam (Cont…)

105

00:12:04,430 –> 00:12:09,860

Just press it to make sure it’s flat for about 30 seconds.

106

00:12:11,520 –> 00:12:17,810

And then we can just hold it together and squeeze it. You only need two adjusting screws to swing this mirror around.

107

00:12:17,830 –> 00:12:26,370

That one is just a pivot point. And so I’ve set that pivot point to a fixed position, and that will leave a gap of about one and a half millimeters.

108

00:12:26,910 –> 00:12:36,480

When we plug this through here like this, there’s a hole in the bottom there into which that pin fits like that.

109

00:12:38,130 –> 00:12:45,900

The act as a pivot now for the mirror and then we put a spring on there and name three net and then I can just tighten up the nut.

110

00:12:46,230 –> 00:12:51,390

So we’ve tightened that spring up in there so that we’ve got about two or three millimeters of movement left on that spring.

111

00:12:52,380 –> 00:12:56,610

Okay, now we can tighten up these two screws on the back here.

112

00:12:57,090 –> 00:12:59,100

Now those screws drop into little pockets.

113

00:12:59,400 –> 00:13:09,300

And as we tighten the screws up, we get movement this way, which is basically directing the beam up and down by adjusting the top want.

114

00:13:10,200 –> 00:13:12,060

So as you can see, we’re now just the top one.

115

00:13:12,930 –> 00:13:21,780

What happens is this fixed pivot and this screw o’clock hinge and they cause this plate to move like that.

116

00:13:22,380 –> 00:13:28,440

And then when I want to move the being from left to right, well, it just this one because this one.

117

00:13:31,170 –> 00:13:35,820

Move the plate like that because it’s pivoted between there and that’s grew.

118

00:13:36,090 –> 00:13:39,720

So we’ve changed the hinge from that direction to that direction.

119

00:13:39,810 –> 00:13:45,780

So we get nice clean motion. We don’t get if you have a triangular system, you get strange motion.

120

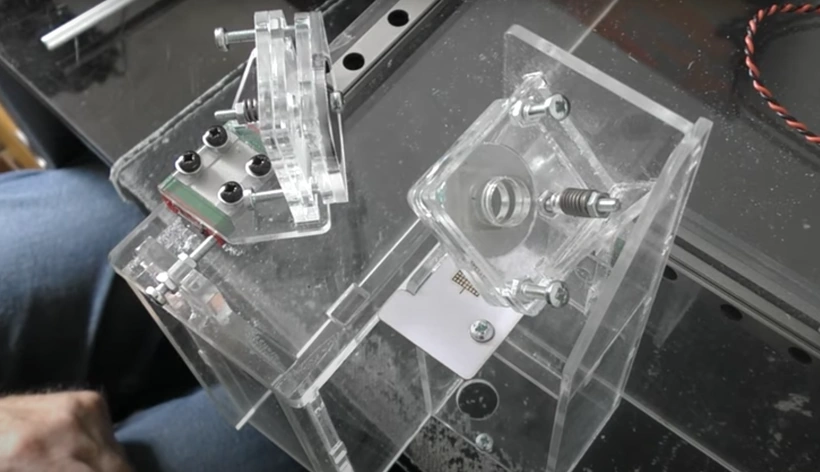

00:13:46,050 –> 00:13:54,270

Now you’ll notice also that I’ve managed to get this mirror working with just one spring strategically put into the right place, I might add.

121

00:13:54,270 –> 00:13:58,500

But it’s only one spring that’s required to make this mirror system work.

122

00:13:58,830 –> 00:14:07,200

I’ve now got to manufacture some 25 millimeter acrylic mirrors, nice and cheap, to fit into this system.

Transcript for How to Align a Laser Beam (Cont…)

123

00:14:07,200 –> 00:14:09,210

I have got some molybdenum mirrors,

124

00:14:09,540 –> 00:14:17,160

but molybdenum mirrors will change the setup of the system because molybdenum mirrors will reflect off the front face of the mirror,

125

00:14:18,060 –> 00:14:24,570

whereas this mirror is sitting right at the back here and reflects three millimeters deeper.

126

00:14:24,630 –> 00:14:29,250

Now, that might not sound a lot, but it will make a big difference to the way in which the system sets up.

127

00:14:29,250 –> 00:14:33,600

We’ve got to make sure that the laser pointer is a snug fit.

128

00:14:36,150 –> 00:14:44,980

In this whole here. And it is too snug at the moment because I’ve purposely made that about 0.1 millimeter and the size to what it needs to be.

129

00:14:45,540 –> 00:14:52,380

So here I’ve got a six millimeter drill and I’m basically going to use that like a Rhema and I’m just going to put that through there.

130

00:14:52,410 –> 00:15:01,050

But you see how easy it went through. But I’ve got to rotate it several times to take just a little teeny weeny bit of material out of there.

131

00:15:11,900 –> 00:15:16,660

And hopefully that should be enough material removed to allow me to slide,

132

00:15:16,660 –> 00:15:20,320

not slide, but I’ve got to force now, make sure we put it in the right way round.

133

00:15:23,080 –> 00:15:24,750

So the Greenpeace goes on the front.

134

00:15:24,760 –> 00:15:31,060

There’s a little teeny weeny hole up there to round about 10:00, and that matches up on the center of that hole there.

135

00:15:31,780 –> 00:15:39,670

So again, we’ve got our screw to go through there, which will help line everything up.

136

00:15:40,690 –> 00:15:45,040

But before we do that, we’ve got to do two things.

137

00:15:45,040 –> 00:15:49,630

First of all, we must make sure that we put this through here to start with.

138

00:15:50,470 –> 00:15:55,660

Otherwise, we’re going to be in trouble. And then that should.

139

00:15:58,490 –> 00:16:01,370

If I’m lucky, I might have to use.

Transcript for How to Align a Laser Beam (Cont…)

140

00:16:03,710 –> 00:16:12,440

My electrical pliers, which have got a nice curve in the end there, just to hold onto part of that and give it a twist and a push.

141

00:16:13,100 –> 00:16:15,770

And there we are. That’s nearly flush with the front of the whole now.

142

00:16:16,850 –> 00:16:24,239

So what we do is just put this piece of black plastic on this piece of opaque plastic on, which is important for that whole game.

143

00:16:24,240 –> 00:16:30,050

We need to line these up before we lock this screw up again.

144

00:16:30,460 –> 00:16:40,470

We’ve got to put glue down between these plates. And that should be sufficiently loose that it almost comes out the bottom.

145

00:16:42,120 –> 00:16:48,840

We just turn it over and put a little bit in the bottom. Okay.

146

00:16:49,860 –> 00:16:53,110

Now we do that same trick that we did before. Make sure you keep your fingers dry.

147

00:16:53,130 –> 00:17:06,800

Otherwise, a stick. The edge is nice and square.

148

00:17:08,210 –> 00:17:15,240

Put that into its pocket. If we put that screw right through.

149

00:17:19,220 –> 00:17:27,420

Spring on the back. So would you set the plate up square?

150

00:17:27,870 –> 00:17:29,490

Although that’s not the right target.

151

00:17:30,000 –> 00:17:39,450

Do you see that the center line should be about here somewhere so we can adjust it left and right on to center, nice and smoothly.

152

00:17:39,540 –> 00:17:44,400

Now, one of the important aspects that I haven’t spoken about yet, but we will when we come to setting it up,

153

00:17:45,270 –> 00:17:51,820

is the reason why I’ve got the laser and mirror one on the same plate.

154

00:17:51,840 –> 00:17:59,450

They’re not separate. They’re together because you’ve just seen me set the beam up onto mirror one.

Transcript for How to Align a Laser Beam (Cont…)

155

00:17:59,460 –> 00:18:05,970

And look, no matter where I move the laser beam, it’s always in the middle of mirror one.

156

00:18:06,000 –> 00:18:10,140

You can’t do that with any of the laser machines that you’ve bought. I can guarantee that.

157

00:18:11,070 –> 00:18:17,040

Okay, so I’ve added my extra three millimeter plate on the bottom there and I’ve got to put this guide plate on the corner here.

158

00:18:17,430 –> 00:18:21,360

And I think what I’d do is just something like that, hold it against the edge,

159

00:18:21,360 –> 00:18:25,290

which is where I know it’s got to go and I’ll try and clamp it in that position.

160

00:18:32,150 –> 00:18:36,590

Make sure there’s none on the outside. Just make sure push it up against it tight.

161

00:18:36,950 –> 00:18:44,630

So that’s really just a reference age to keep this in a straight line and you’ll understand why I’m doing that at a later date.

162

00:18:45,470 –> 00:18:52,370

I also made two three millimeter acrylic mirrors. So the government target just sits in there.

163

00:18:54,890 –> 00:18:59,270

And regardless of how I move this around, the target doesn’t change.

164

00:19:01,340 –> 00:19:12,030

Now I’ve got an additional hole in here that passes right the way through and I’ll drop a screw into that because that represents the No.

165

00:19:12,030 –> 00:19:22,040

One to set up position for the mirror. Well, I have to say, things are going quite well so far because I’ve got my parallel here, parallel here.

166

00:19:22,760 –> 00:19:27,170

And my target is my laser beam is virtually in the center of the target.

167

00:19:27,770 –> 00:19:34,070

So I’ve only got the smallest adjustment to do on here to get it set right on the top spot on the center of the target.

168

00:19:34,100 –> 00:19:40,100

But what we have to remember is that this beam is not hitting the surface of the mirror.

169

00:19:40,280 –> 00:19:47,270

This beam is hitting the back surface of the mirror. So it’s not actually hitting the center of the mirror as that target indicates.

170

00:19:47,480 –> 00:19:51,890

Hit it. If it was a surface mounted mirror, it would be hitting the center of the mirror.

171

00:19:51,950 –> 00:19:56,659

Now, this is the frame of a mirror to it’s virtually exactly the same as everything else,

172

00:19:56,660 –> 00:20:01,820

except it’s on a different baseplate with four fixing holes on it to fix onto the bearing.

Transcript for How to Align a Laser Beam (Cont…)

173

00:20:02,360 –> 00:20:08,570

So we then clamp it down while it dries. And look, we make sure we don’t stick it to the plywood.

174

00:20:09,990 –> 00:20:14,750

We’ll move it around a few times and again, make sure everything is nice and square and uniform.

175

00:20:18,240 –> 00:20:24,420

No poke the mirror through the hole and locate the mirror on its pivot point at the front corner here.

176

00:20:24,420 –> 00:20:31,650

If you remember, we spring the name through, not the parallel gap there.

177

00:20:31,710 –> 00:20:39,660

Parallel gap there. We ready to assemble now acoustic the mirror zoom with a piece of double sided, strong, double sided tape.

178

00:20:41,280 –> 00:20:45,390

Well, that’s not going to come out double sided tape, but if I wanted to,

179

00:20:46,140 –> 00:20:49,200

I’ve got a hole through the back there so I can actually push the whole thing out.

180

00:20:49,980 –> 00:20:57,420

This is only three millimeters thick. The hole in the bearing is about three, maybe four millimeters thick.

181

00:20:57,870 –> 00:21:00,899

So really, I could do with an end three by six long.

182

00:21:00,900 –> 00:21:04,320

Well, I haven’t got that. I’ve got this eight millimeter long thread.

183

00:21:05,100 –> 00:21:13,140

So what I’m going to do is to put a washer and a critical washer underneath it, and that should take up the difference.

184

00:21:14,640 –> 00:21:24,220

Oh, yes. Perfect. That’s nice and snug. It’s a great feeling when a plan comes together.

185

00:21:28,390 –> 00:21:33,880

Look at that. These are the pieces for the heat. These are the pieces of the hate mounting bracket.

186

00:21:34,510 –> 00:21:38,290

And these pieces you’ll recognize here for the mirror that goes on, the hate.

187

00:21:39,070 –> 00:21:46,930

So I think we might start off by mounting a mirror on this st hate piece.

188

00:21:47,530 –> 00:21:53,350

So if you remember, we have the hexagon holes in front of the plain holes.

189

00:21:54,980 –> 00:22:03,480

And we need to squares and the right hand side. Then we can put this in the back.

Transcript for How to Align a Laser Beam (Cont…)

190

00:22:08,200 –> 00:22:13,720

Like that. And then that sits on there.

191

00:22:14,530 –> 00:22:17,560

So get my piece of estate material out. Piece of plywood.

192

00:22:17,920 –> 00:22:26,710

We put some glue down the edge of the bracket and along from the front.

193

00:22:29,580 –> 00:22:34,410

In the back. The plate.

194

00:22:35,880 –> 00:22:39,590

And while we’re here, we might as well. Sticks and glue.

195

00:22:42,140 –> 00:22:46,820

And between the plates as well. Okay, now you try and hold the whole thing together.

196

00:22:47,690 –> 00:22:50,690

Just move it around to make sure there’s no glue underneath it sticking.

197

00:22:51,470 –> 00:23:00,710

Okay, so now we can build the rest of the aid, and the sensible way to do this is to pick this piece up.

198

00:23:06,260 –> 00:23:11,210

Put it on its side. So put these two pieces to the top like that.

199

00:23:11,630 –> 00:23:18,360

Both the same way. Okay.

200

00:23:18,460 –> 00:23:22,510

So that’s fairly stable and then we can pop this side piece on.

201

00:23:22,840 –> 00:23:28,090

There is only one way for this to go. Square corner at the top here.

202

00:23:28,270 –> 00:23:34,310

All the others have got around the soft edge on the heat assembled, and it’s completely stable now.

203

00:23:34,600 –> 00:23:43,780

So it would kind of be rotated onto its front like that. And then we can hold this between the tongues.

204

00:23:43,900 –> 00:23:46,590

Don’t put your finger on the tongue because you’re getting stuck.

205

00:23:48,220 –> 00:23:54,790

This package and this front edge mean we can hold the whole thing together for around about 30 seconds.

206

00:23:55,420 –> 00:24:07,480

Now it’s reasonably stable. Okay, so what we can do now is we can pop glue round the top faces, these side pieces.

Transcript for How to Align a Laser Beam (Cont…)

207

00:24:07,690 –> 00:24:12,100

One, two, three and two, three.

208

00:24:12,370 –> 00:24:18,640

There we go. That’s done. Those tongues pass through the slots like that.

209

00:24:19,600 –> 00:24:25,360

And then this piece lays on the back, put the tongues upwards, and it’ll sit all flat on the back then.

210

00:24:26,200 –> 00:24:36,830

And we need to drop some glue. Into these four tongues, and you’ll see that the glue will actually run between the plates as well.

211

00:24:37,310 –> 00:24:42,170

Something I haven’t done. I’ve just noticed. I should have counted.

212

00:24:42,230 –> 00:24:49,520

Sunk these holes here. And if we’ve got that right, that should fit on their.

213

00:24:53,710 –> 00:24:57,600

And give us a nice vertical adjustment, is it?

214

00:24:58,150 –> 00:25:02,440

And then I find this is a difficult task to get this backing off.

215

00:25:02,440 –> 00:25:07,090

But I generally find that a pair of tweezers is one of the best things for lifting it off with.

216

00:25:09,260 –> 00:25:12,380

When? Okay.

217

00:25:16,540 –> 00:25:19,830

And there we go. That’s never going to come out of nowhere.

218

00:25:20,260 –> 00:25:23,370

These holes in them are going on to the bearing block.

219

00:25:23,380 –> 00:25:24,610

We’re nearly there now.

220

00:25:25,480 –> 00:25:39,400

We could have put the screw in the nut through those holes spring and a nut to hold on with some in three by 12 millimeter co two some screws.

221

00:25:39,820 –> 00:25:43,990

Hopefully they should be the right size to pass through here.

222

00:25:46,240 –> 00:25:51,740

You know, maybe they’re too long gone. Can grind a couple of millimeters off the end of the screws.

223

00:25:53,330 –> 00:25:58,500

So just fix our mounting plate. So we’ve got one more job to do.

224

00:25:59,100 –> 00:26:02,640

Taking the 25 millimeter long screw and I’m winding and not on.

Transcript for How to Align a Laser Beam (Cont…)

225

00:26:02,970 –> 00:26:07,470

And then we pass through that hole now and we’ve got another nut on the other side.

226

00:26:07,830 –> 00:26:14,400

Now, those two nuts, they form a solid a stop for this slide.

227

00:26:15,450 –> 00:26:19,020

You see the reason for having an adjustable. Why?

228

00:26:19,800 –> 00:26:23,300

Because all I’ve got on the head here as an adjustable Z.

229

00:26:24,540 –> 00:26:31,620

Whereas in the previous design, which we had, which was this one, remember, which climbed down to the top.

230

00:26:32,160 –> 00:26:38,190

What we had, we had an adjustable Y and an adjustable Z built into this bracket.

231

00:26:38,880 –> 00:26:43,590

Well, I’m pretty happy with that. It all feels lovely. No swap at all.

232

00:26:44,400 –> 00:26:53,460

So that’s a very good simulation of a machine. Not a complete machine, but enough to show and demonstrate how to set a beam accurately.

233

00:26:53,670 –> 00:27:03,210

Now, I’ve created these targets, and unlike normal targets, these are not going to get thrown away because we’ve got no lighter burning at Target.

234

00:27:04,350 –> 00:27:09,390

That little square reference in the center there is marked in one millimeter squares.

235

00:27:09,630 –> 00:27:13,580

And remember, the beam itself is about one millimeter diameter.

236

00:27:13,590 –> 00:27:19,630

So we should be able to get an idea pretty accurately of where the beam is at each end of the well.

237

00:27:19,650 –> 00:27:25,560

Before we go anywhere near the simulator, we need to understand what it is that we’re trying to achieve.

238

00:27:26,280 –> 00:27:34,470

Now, I have to admit, I was guilty of all sorts of misdemeanors about lenses when I first started playing with these laser machines.

239

00:27:34,650 –> 00:27:40,890

My ignorance was immense, and it’s only gradually decreased with time.

240

00:27:41,640 –> 00:27:50,910

So I’m going to give you guys a flying start. The first thing we will say is that a lens is manufactured with something called spherical geometry.

241

00:27:51,450 –> 00:28:01,800

Now, look, that means that it is part of a sphere, and a sphere has an axis about which it pivots and rotates.

Transcript for How to Align a Laser Beam (Cont…)

242

00:28:02,580 –> 00:28:06,840

And look, that axis passes right through the lens.

243

00:28:07,740 –> 00:28:17,190

So that is the axis of the lens. It is the axis that would pass through the center of the sphere if the rest of the sphere was there.

244

00:28:17,580 –> 00:28:20,940

But we’re only going to use this part at the top here as the lens.

245

00:28:21,360 –> 00:28:25,320

Here is what we are trying to achieve without being set up.

246

00:28:25,530 –> 00:28:34,020

The laser beam hitting mirror number three and bouncing downwards so that it passes right through the axis of the lens.

247

00:28:34,950 –> 00:28:41,790

Now the lens works because it has parallel rays of light hitting this curve surface.

248

00:28:42,180 –> 00:28:50,219

And those parallel rays of light get refracted off that curved surface in various degrees to come down to something called a focal point,

249

00:28:50,220 –> 00:28:53,940

which is just here. That is perfection. It is very,

250

00:28:53,940 –> 00:28:59,999

very difficult to achieve that condition because the Chinese don’t make it

251

00:29:00,000 –> 00:29:04,980

easy with the design of their machines to allow you to achieve that setting.

252

00:29:05,910 –> 00:29:09,450

I’m not saying it’s impossible. I’m just saying it’s close to impossible.

253

00:29:10,350 –> 00:29:18,480

Now, the most likely situation that you’re going to encounter is that your beam hits the mirror at somewhere other than the sweet spot.

254

00:29:19,290 –> 00:29:27,840

Now, the sweet spot is that point on the mirror, which will reflect the beam perfectly downwards and through the axis of the lens.

255

00:29:28,470 –> 00:29:36,060

As you can see in this case, we’ve hit another spot, which is not the sweet spot, and we’re not passing through the central axis of the lens now.

256

00:29:36,270 –> 00:29:41,400

But I’ve just drawn a single line for my beam. But as I said, the beam is this wide.

257

00:29:41,730 –> 00:29:46,080

But this is effectively the path of the most intense part of the beam.

258

00:29:46,710 –> 00:29:50,220

And it’s the intense part of the beam that does damage to material.

259

00:29:50,520 –> 00:29:57,899

So if we follow this beam, you’ll see that it is not passing through the axis of the lens and is actually being refracted towards the

260

00:29:57,900 –> 00:30:04,950

focal point because all parallel rays will pass through the lens and get refracted to this focal point.

Transcript for How to Align a CO2 Laser Beam (Cont…)

261

00:30:05,610 –> 00:30:11,880

But hey, look, this is the most powerful part of the beam, and it’s going to pass through the focal point at an angle.

262

00:30:13,050 –> 00:30:19,410

That means that your cut is going to be at an angle because this is the most powerful cutting part of the beam.

263

00:30:19,740 –> 00:30:21,840

This part here is relatively unimportant.

264

00:30:22,020 –> 00:30:27,600

And this bit here, well, it’s missed the lens altogether, and it’s probably heating up the inside of your lens tube.

265

00:30:28,740 –> 00:30:36,330

Now, here we’ve got another potential situation that happens, and that is that the beam.

266

00:30:37,530 –> 00:30:40,590

May not be coming in. Absolutely true.

267

00:30:40,920 –> 00:30:44,400

Although it’s running through the center of the lens at the contact point,

268

00:30:44,550 –> 00:30:51,540

although these rays are still coming in parallel, they’re not coming in at the correct angle to the face of the lens.

269

00:30:51,540 –> 00:30:54,000

They’re not parallel with the axis of the lens.

270

00:30:54,360 –> 00:31:01,200

And because they’re not parallel with the axis of the lens, they will fly off an angle like this and they will miss the focal point.

271

00:31:02,550 –> 00:31:07,860

So hey, you’ll probably find yourself hitting the inside of your nozzle if you’ve got a small home nozzle.

272

00:31:08,190 –> 00:31:12,900

And secondly, look, the most powerful rays are also running off at an angle.

273

00:31:13,170 –> 00:31:18,120

So again, there’s another reason why you produce an angled cut on the edge of your material.

274

00:31:18,630 –> 00:31:21,900

So these are the two things that we’re trying to overcome and ignore.

275

00:31:21,960 –> 00:31:25,110

This is what we’re after. This is setting perfection.

276

00:31:25,620 –> 00:31:33,180

If you get the beam passing through the central axis of the lens, it will pass through the center of your nozzle as well.

277

00:31:34,140 –> 00:31:38,700

You must not attempt to set the beam up through the center of the nozzle.

278

00:31:39,810 –> 00:31:43,650

You must attempt to set the beam up through the axis of the lens.

279

00:31:44,370 –> 00:31:48,870

Checking that it passes through the center of the nozzle is just a check.

280

00:31:49,740 –> 00:31:57,060

It’s not a setting point. Okay, now, here is a point that I was very ignorant of when I first started setting beams up.

281

00:31:58,050 –> 00:32:06,420

This is mirror number one. And here is the laser tube up here firing the beam at mirror number one.

Transcript for How to Align a CO2 Laser Beam (Cont…)

282

00:32:08,820 –> 00:32:21,180

I believed that probably the best way to say it was to make sure that my tube, oh, my beam was running absolutely parallel with my gantry rubbish.

283

00:32:21,390 –> 00:32:26,129

It turns out that it doesn’t matter what angle you set your tube at.

284

00:32:26,130 –> 00:32:34,890

Wherever you fire the beam at mirror one mirror one has the ability to rotate and be set so that you can even this beam here,

285

00:32:34,890 –> 00:32:41,970

which is incorrectly firing at mirror one, you can rotate mirror one and make it come out in this angle.

286

00:32:42,210 –> 00:32:45,840

So it doesn’t matter how you set the tube up.

287

00:32:46,680 –> 00:32:52,740

The only thing that’s important about setting mirror number one up is that the beam

288

00:32:52,980 –> 00:32:59,790

should hit the center of the mirror to give you the maximum scope of use of the mirror.

289

00:33:00,570 –> 00:33:07,260

Let me explain. You probably have a 20 probably a 25 millimeter mirror.

290

00:33:07,890 –> 00:33:15,300

Part of that will be masked by the frame. So you may well only have as much as 23 millimeters clear mirror.

291

00:33:15,780 –> 00:33:21,780

But when you fire the laser beam at it at 45 degrees, this is what the laser beam sees.

292

00:33:22,230 –> 00:33:30,180

It sees 23 millimeters top to bottom. But from side to side, that is round about 13 or 14 millimeters.

293

00:33:31,320 –> 00:33:37,230

So we’ve got to be reasonably accurate left to right when we come to set up our beam.

294

00:33:38,010 –> 00:33:43,350

And the ideal situation is to set the beam at mirror one right in the center.

295

00:33:43,920 –> 00:33:51,510

But if it’s a one or two millimeters high or low, as you can see, it isn’t really going to affect anything.

296

00:33:51,780 –> 00:33:56,790

So don’t get too anal about getting it perfectly on the center of the mirror.

297

00:33:57,390 –> 00:34:01,650

Lots of people believe that is the only place to set the be wrong.

Transcript for How to Align a CO2 Laser Beam (Cont…)

298

00:34:01,950 –> 00:34:05,790

You have some flexibility north and south when you set mirror number one.

299

00:34:07,140 –> 00:34:10,790

If you follow this through to mirror number two, it’s exactly the same picture.

300

00:34:10,800 –> 00:34:15,480

So you’ve got flexibility north and south for mirror number two.

301

00:34:16,380 –> 00:34:21,660

But of course, when we get to mirror number three, the situation is reversed.

302

00:34:22,170 –> 00:34:25,860

We’ve got a lot more horizontal flexibility.

303

00:34:26,110 –> 00:34:29,160

Mirror three and not much vertical.

304

00:34:30,670 –> 00:34:39,430

But on the other hand, as I just described to you when I spoke about lenses, there is something on this mirror called a sweet spot.

305

00:34:40,570 –> 00:34:45,970

You might normally be aiming for the center of the mirror when you set the beam up in this general direction.

306

00:34:47,020 –> 00:34:52,780

But what we really interested in is making sure the beam hits the so-called sweet spot that’s on that mirror.

307

00:34:53,740 –> 00:34:59,440

So let’s take a look at the first axis that we’re trying to align, which is the Y axis down side of the machine.

308

00:34:59,950 –> 00:35:07,660

The beam comes in, bounces off of mirror one, and ideally it passes along this line here,

309

00:35:08,230 –> 00:35:14,650

which is absolutely parallel and true to this white block here, which is the bearing rail.

310

00:35:15,940 –> 00:35:23,200

And that’s the aim of the exercise. We’ve got to get that beam running true to the axis bearing rail.

311

00:35:26,590 –> 00:35:36,370

And as you can see here, I’ve got absolute perfection. I’m bouncing off of mirror one and I’ve passing through mirror number two on its center point,

312

00:35:36,970 –> 00:35:44,350

both here with its close to mirror number one, and here when it’s furthest away from mirror number one.

313

00:35:44,650 –> 00:35:49,000

So that’s A and B are the two positions for mirror two.

314

00:35:51,880 –> 00:36:01,750

What chance have we got of doing that? Well, it’s a pretty difficult task that people just do not seem to understand.

Transcript for How to Align a CO2 Laser Beam (Cont…)

315

00:36:02,230 –> 00:36:07,420

And let me explain why it’s not a simple task.

316

00:36:08,170 –> 00:36:15,790

It’s a very tedious task that depends on a process of something called iteration,

317

00:36:16,390 –> 00:36:22,030

which means you don’t get it right first time you get it a little bit better than it was before.

318

00:36:22,270 –> 00:36:25,690

And then you try again and you get a little bit better again.

319

00:36:25,900 –> 00:36:30,730

And you try again and again and again. That’s what iteration is.

320

00:36:31,570 –> 00:36:36,820

And that’s what we’re going to show you here, how important that process of iteration is to setting the beam.

321

00:36:37,000 –> 00:36:42,820

You’re not going to set a beam up in one hit for the purpose of this exercise.

322

00:36:43,450 –> 00:36:47,410

I’m going to move my mirror one out of position.

323

00:36:48,010 –> 00:36:53,080

That’s where I had it set for perfection. And I’m now going to move it out of position.

324

00:36:53,410 –> 00:37:02,050

And this is this could easily be your machine. You don’t know the relative positions of Mirror one and mirror two.

325

00:37:02,080 –> 00:37:07,840

Hopefully, the Chinese have managed to get them reasonably close together, but you can’t be sure.

326

00:37:08,260 –> 00:37:11,560

So let’s tackle it from this position. Okay.

327

00:37:11,570 –> 00:37:18,400

The beam comes in batches of mirror one and reflects right down at the end of the stroke.

328

00:37:18,820 –> 00:37:29,770

Now this is not laser beam alignment, so we have to adjust mirror one so that our beam at least appears on mirror to at its extreme position.

329

00:37:30,340 –> 00:37:36,760

Okay, so we’ve got a target on here and we’ve probably just burned a little mark on the target.

330

00:37:37,210 –> 00:37:43,990

And when we move back to the beginning here, we’ll put a clean target on here and we will burn a mark.

331

00:37:44,350 –> 00:37:50,800

Now, if you look very closely, you’ll see that I have simulated a little burn mark on there with a circle.

332

00:37:51,250 –> 00:37:57,040

So that little burn mark there at a is what I will call the target mark.

333

00:37:57,460 –> 00:38:06,100

So when we move A to position B and there’s the target mark there, what we’ve now got to do,

Transcript for How to Align a CO2 Laser Beam (Cont…)

334

00:38:06,400 –> 00:38:13,090

we’ve got to adjust mirror one so that the beam hits the target mark.

335

00:38:13,420 –> 00:38:17,870

Let’s look what’s happened to the beam at Position A.

336

00:38:18,400 –> 00:38:25,170

So although we’ve moved this target mark to Position B and we’ve hit the target at position B because we’ve adjusted the mirror,

337

00:38:25,180 –> 00:38:30,250

look, it’s no longer on the target, mark. We’ve created a new mark here.

338

00:38:30,670 –> 00:38:37,840

We’ll move the mirror back to position A we’ll put a new target on and we’ll create a new target mark.

339

00:38:38,440 –> 00:38:45,100

Then we move from position to position B and look, our target is not matching the beam.

340

00:38:45,340 –> 00:38:47,740

We have to make the beam hit our target.

341

00:38:48,190 –> 00:38:55,269

But think about we’ve already been running this loop once because by adjusting mirror one, we’ve moved away from the target.

342

00:38:55,270 –> 00:39:00,700

Mark, bring the mirror back to position. We take a new target and we have to burn another target.

343

00:39:00,700 –> 00:39:11,850

Mark. And we move that target mark to position be look it means.

344

00:39:13,130 –> 00:39:17,750

So no, we’ve got to adjust the beam to hit this target.

345

00:39:17,990 –> 00:39:25,900

I have already seen as soon as we adjust the beam onto the target position, be look what we’ve done at position.

346

00:39:27,200 –> 00:39:37,400

We’ve missed the target again. We have not got the beam passing through the same point at A and B, so we’ve got to create yet another target.

347

00:39:37,970 –> 00:39:42,080

And we go through exactly the same process again and again and again.

348

00:39:42,230 –> 00:39:46,340

And eventually we get to this point where we’re getting a bit fed up and we still haven’t got it right.

349

00:39:46,370 –> 00:39:51,070

Look, there’s my final attempt. I’m going to say, damn, I’ve run out of patience.

350

00:39:51,650 –> 00:40:01,400

But look, I’ve run out of patience, but I still haven’t got absolute perfection between position A and position B,

Transcript for How to Align a CO2 Laser Beam (Cont…)

351

00:40:01,760 –> 00:40:08,150

which means that my beam is not perfectly aligned to the axis.

352

00:40:08,330 –> 00:40:13,190

It’s very nearly aligned to the axis, but not perfectly.

353

00:40:13,790 –> 00:40:23,510

And that can have an effect later on. The fact that we haven’t got that beam running exactly parallel to the axis, but you get the idea.

354

00:40:23,540 –> 00:40:32,990

Look, it’s taking me one, two, three, four, five, six attempts to get that beam parallel to the axis.

355

00:40:33,740 –> 00:40:36,920

I can’t cheat. It’s taking me six.

356

00:40:38,120 –> 00:40:42,170

If you can get it done in two. It means, well, you’re nearly there.

357

00:40:42,650 –> 00:40:47,570

But trust me, you can see that even with six attempts, I have not got perfection.

358

00:40:48,170 –> 00:40:53,930

You can’t see that degree of imperfection with a burnt beam.

359

00:40:54,920 –> 00:40:59,150

It’s very, very difficult to see that degree of perfection.

360

00:40:59,420 –> 00:41:06,080

So the chances are that after three, maybe four, possibly you will think, oh,

361

00:41:06,200 –> 00:41:13,400

I’ve now got perfection of demonstrated to you that six, seven, eight times, and you still have perfection.

362

00:41:13,790 –> 00:41:17,510

You’ve got near perfection three or four attempts.

363

00:41:18,440 –> 00:41:28,520

So this process of iteration is a very important point for you to remember when you’re setting up your be patients, patients, patients.

364

00:41:30,510 –> 00:41:34,890

Now, that process that I’ve just described there.

365

00:41:36,450 –> 00:41:40,390

Is from mirror one along the y axis.

366

00:41:41,010 –> 00:41:46,320

This could equally well be mirror two and this could be the x axis.

367

00:41:46,860 –> 00:41:52,260

This could equally well be mirror three. And this could be the Z axis.

368

00:41:53,910 –> 00:42:02,910

It doesn’t matter what axis you’re working on. This process of iteration is exactly the same for every axis.

Transcript for How to Align a CO2 Laser Beam (Cont…)

369

00:42:03,840 –> 00:42:11,460

Okay, so here we have beam simulator, laser tube out here with a beam coming out hitting mirror number one.

370

00:42:12,570 –> 00:42:16,980

Mirror number two, move backwards and forwards as per machine.

371

00:42:17,760 –> 00:42:21,690

And mirror number three, moves as a machine.

372

00:42:22,410 –> 00:42:27,120

Although there’s no gantry on here, this is a simulated position for the end of the gantry.

373

00:42:27,600 –> 00:42:30,030

So we should be able to simulate setting the beam up,

374

00:42:30,360 –> 00:42:36,810

passing through three mirrors and finishing up at this point here, which is the axis of the lens.

375

00:42:37,200 –> 00:42:40,769

I’m not going to be able to get that perfection that I’ve just described to you,

376

00:42:40,770 –> 00:42:47,610

that theoretical perfection that allows me to go five, six, seven or eight times to get the perfect beam.

377

00:42:47,970 –> 00:42:51,960

We’re going to find it after maybe three, maybe four attempts.

378

00:42:52,110 –> 00:43:00,960

And that’s about as much as we can go. And we just have to accept the fact that there is going to be a degree of imperfection in our settings.

379

00:43:01,320 –> 00:43:11,459

Now, the first thing that I must state is I’ve removed the acrylic mirrors because they were starting to become a bit of a nuisance.

380

00:43:11,460 –> 00:43:14,040

When I did a quick experimental test,

381

00:43:14,550 –> 00:43:22,740

bouncing off the back of the mirror is completely different to bouncing off the front face of these molybdenum mirrors that I’ve got in here now.

382

00:43:23,730 –> 00:43:28,950

So I’ve had to go for the real thing in the end, real bearings, real mirrors.

383

00:43:29,760 –> 00:43:33,959

So we’ve got a pretty good, real simulation, as you can probably see there.

384

00:43:33,960 –> 00:43:36,180

Look at switching the laser tube on and off.

385

00:43:36,180 –> 00:43:43,710

You see that this screw is not only the fixing for the spring on the back, but I’m using it as a location for the target as well.

386

00:43:44,040 –> 00:43:48,690

And I’m locating off the bottom here to keep everything nice and true and square.

387

00:43:48,750 –> 00:43:52,900

There is. It’s not in the center.

388

00:43:54,180 –> 00:43:58,409

So remember the way in which the laser beam worked?

389

00:43:58,410 –> 00:44:05,790

If I go to the top, I should be able to make it go up and down and I can do so.

Transcript for How to Align a CO2 Laser Beam (Cont…)

390

00:44:05,790 –> 00:44:12,060

Let’s put that on to center line. And now we go to the bottom one and that moves it left to right.

391

00:44:13,140 –> 00:44:17,250

And I can move it left to right, as you can see. So let’s put that on center as well.

392

00:44:17,250 –> 00:44:25,590

So there we go. That’s nice and easy. You can’t do that as easily with your beam, but that’s what you’ve got to ideally achieve.

393

00:44:27,870 –> 00:44:33,450

So now we backed the beam off of mirror one onto mirror number two.

394

00:44:34,560 –> 00:44:38,870

We’ve got a target there. And it’s way off.

395

00:44:39,410 –> 00:44:45,260

So let’s move it to position B and you can see that the beam is way off the center of the target.

396

00:44:45,380 –> 00:44:50,840

What we’ll do, we will set that so that it goes onto the center of the target like that.

397

00:44:51,140 –> 00:44:54,280

Okay. Job done. Or is it?

398

00:44:55,120 –> 00:44:59,710

Let’s move back to position. And you see that job is not done.

399

00:44:59,950 –> 00:45:03,489

We’re nowhere near parallel. Okay.

400

00:45:03,490 –> 00:45:11,380

So what we’ve got to do now is to say, well, look, if that is our target and it’s way off.

401

00:45:12,130 –> 00:45:16,080

But if that is our target, let’s just try and make a note of where it is.

402

00:45:16,090 –> 00:45:25,660

Look, it’s just above. It’s a bear on the end of the crosshair, and it’s just a single dot, maybe one millimeter above the crosshair.

403

00:45:25,960 –> 00:45:32,580

So it’s about one millimeter off the end of the crosshair and one millimeter above the end of the crosshair at position.

404

00:45:33,100 –> 00:45:41,770

Now, I mustn’t change that because that’s my target. So we know move to position B and of course it’s way off target.

405

00:45:42,190 –> 00:45:47,500

What we’ve got to do now is to move this beam about a millimeter above.

406

00:45:48,870 –> 00:45:54,450

Across here and a millimeter beyond the cross here about there.

407

00:45:55,350 –> 00:45:58,710

But let’s have a look what happens when we bring it back to position.

408

00:45:58,800 –> 00:46:02,640

A Well, we’re now about three millimeters.

409

00:46:04,360 –> 00:46:13,000

Off of our target. That’s our new target. So you’ve got to remember that one millimeter high and three millimeters wide.

410

00:46:13,480 –> 00:46:19,570

So we’re okay height wise, but width wise we’ve got to go to about three millimeters, which is about there.

411

00:46:19,750 –> 00:46:22,300

And that looks to be about right.

412

00:46:23,920 –> 00:46:33,400

So after three attempts, we’ve managed to get that about parallel, i.e. the target that A and the target a B are the same.

413

00:46:34,810 –> 00:46:43,800

Even though we know that they’re not. But within the scope of what we can see, they appear to be the same big problem.

414

00:46:44,310 –> 00:46:48,270

We’re not on the center of mirror number two. How can we deal with that problem?

415

00:46:48,540 –> 00:46:52,440

You cannot fiddle with the screws at mirror number one.

416

00:46:52,830 –> 00:47:00,870

You’ve just used those screws at mirror number one to set the beam parallel to the axis.

417

00:47:01,170 –> 00:47:07,050

You can’t ignore that and just twist those screws to make your being come to the center.

418

00:47:07,620 –> 00:47:11,670

It’s not going to work. So that’s another very important lesson.

419

00:47:12,210 –> 00:47:15,480

There are two parts to aligning a beam with a mirror.

420

00:47:15,990 –> 00:47:20,070

Number one, align the beam parallel with the axis,

421

00:47:20,700 –> 00:47:29,370

and then you have to make a physical mechanical adjustment to the mirror to put the beam onto the center of the mirror.

422

00:47:30,180 –> 00:47:33,600

You cannot steer the beam onto the center of the mirror.

423

00:47:34,200 –> 00:47:39,450

You’ve got to physically catch the beam by adjusting the mirror itself.

424

00:47:39,630 –> 00:47:45,990

In my case, the way that I’ve got my machine set up because I thought about this a long time ago,

425

00:47:46,530 –> 00:47:54,330

about how to best set a machine up and I haven’t yet seen any or me Chinese machines that adopt this process.

426

00:47:54,420 –> 00:47:59,670

I can loosen my screws off and let’s remove this nominal fixing screw.

427

00:48:00,090 –> 00:48:07,880

And this is why I want this reference edge along here, because I can now move this beam backwards and forwards like this.

428

00:48:08,370 –> 00:48:15,570

And hey, can you see the miraculous effect that is having on the position of the beam as it hits mirror number two.

429

00:48:16,020 –> 00:48:21,690

So I can now very accurately set onto the center of mirror to.

430

00:48:23,300 –> 00:48:32,640

Hopefully because I’ve made this a parallel motion along here, I will not have affected the settings on mirror number two.

431

00:48:33,170 –> 00:48:37,100

So technically, we can see there that it’s one millimeter high.

432

00:48:39,640 –> 00:48:44,410

I have made a slight difference because the beam was so far out here to start with.

433

00:48:45,340 –> 00:48:49,150

I was guessing where three millimeters was. I didn’t have an accurate assessment.

434

00:48:49,540 –> 00:48:57,760

So now I’ve got the beam back into the center again. So I’m one line high and half a square to the right.

435

00:48:58,090 –> 00:49:02,650

I’m one line high. And half a square to the right.

436

00:49:03,610 –> 00:49:11,020

The important thing here is that it’s parallel and it’s approximately in the center of the mirror.

437

00:49:11,440 –> 00:49:21,010

Okay. So now you are looking up at mirror number three and here we are at closest to mirror number two.

438

00:49:21,400 –> 00:49:31,270

So let’s first of all, make sure that the beam hits the target at its further most point.

439

00:49:32,050 –> 00:49:38,770

I must make sure that I keep my number two mirror jammed against its end stop.

440

00:49:39,460 –> 00:49:43,500

And to do that, what I’m going to do, I’m going to cheat slightly.

441

00:49:43,540 –> 00:49:48,460

I’m going to keep it against its end stop with a very powerful magnet on the rail.

442

00:49:49,090 –> 00:49:54,590

So I’m going to push that on there and that will keep that locked on to the end stop.

443

00:49:54,790 –> 00:49:57,790

There’s our target furthest away from mirror number two.

444

00:49:58,660 –> 00:50:03,730

And we could really do with adjusting it so that it’s nominally on center.

445

00:50:03,910 –> 00:50:08,290

That may or may not be the sweet spot.

446

00:50:08,320 –> 00:50:11,410

We’re not interested in getting the beam to the center of the mirror here.

447

00:50:11,770 –> 00:50:17,800

We’re more interested in making sure that the beam is running parallel to the x axis.

448

00:50:18,220 –> 00:50:22,209

So we’ve moved our target close to mirror number two.

449

00:50:22,210 –> 00:50:30,370

Now our laser beam is arriving at one square, one line to the right and one line above.

450

00:50:30,760 –> 00:50:35,710

So we’ve got to take that very slightly to make it one line above one line.

451

00:50:37,120 –> 00:50:42,250

To the right. Then we’ll check it again. That’s pretty well lined up now.

452

00:50:42,790 –> 00:50:50,110

We’ve got approximately right in the X-axis, but it’s not spot on centerline and there’s not spot on centerline in the Y axis either.

453

00:50:50,410 –> 00:50:55,690

But let’s not worry about that. We’ll deal with that at the next stage.

454

00:50:55,750 –> 00:51:02,470

The key point here is that we’ve got the beam running true to the x axis.

455

00:51:02,860 –> 00:51:09,310

Okay. So I’m now going to plug my target, the same target into this position here.

456

00:51:10,240 –> 00:51:13,390

Now, hopefully you can see the the red dot on there.

457

00:51:13,930 –> 00:51:22,360

It happens to be two squares to the front and one square to the left of the centerline.

458

00:51:23,140 –> 00:51:33,700

Now, if we’ve got our x axis set up correctly, then theoretically it should remain in this position here.

459

00:51:33,940 –> 00:51:37,060

As I move closer to the mirror.

460

00:51:37,090 –> 00:51:45,830

Number two. The dot is one square to the left and two squares to the front.

461

00:51:46,910 –> 00:51:47,490

So there we go.

462

00:51:47,510 –> 00:52:00,860

We’ve proved now that we’ve got our beam set correct to the x axis, but now we can see that the beam is not correct relative to this z axis.

463

00:52:01,430 –> 00:52:04,490

So here we are close to mirror number three.

464

00:52:04,910 –> 00:52:07,910

And as I said, we are what we are to forward.

465

00:52:08,270 –> 00:52:11,900

And one to the left, the beam is in the middle of that square.

466

00:52:12,710 –> 00:52:16,310

So let’s move that from the top to the bottom.

467

00:52:16,520 –> 00:52:21,290

The beam is a long way off. Exactly the same axis process.

468

00:52:21,860 –> 00:52:25,730

Closing, distant. Closing distant. Closing distant.

469

00:52:26,330 –> 00:52:32,809

So this is we’ve now got to match our target, remember, which was two forward and one to the left.

470

00:52:32,810 –> 00:52:36,020

So to forward, one to the left.

471

00:52:36,230 –> 00:52:42,470

Let’s put it on top again. We know one and a half forward.

472

00:52:44,440 –> 00:52:49,239

Then on centerline down to the bottom again on the centerline.

473

00:52:49,240 –> 00:52:54,850

And one and a half forward. Check. Check on the top on centerline.

474

00:52:55,570 –> 00:53:01,180

And close to one forward. You just tweak again and that’s one forward.

475

00:53:01,390 –> 00:53:07,210

And on centerline, we’ve now achieved the beam passing parallel.

476

00:53:08,590 –> 00:53:17,860

To the axis of the lens. It’s not on the axis of the lens because the beam is not passing through the crosshair.

477

00:53:18,250 –> 00:53:23,890

The problem is, how do we get. That on the cross here.

478

00:53:25,570 –> 00:53:29,200

Again, this is something that you will not have on your machine,

479

00:53:29,590 –> 00:53:34,600

but you really want it on your machine because the only way that you can achieve

480

00:53:34,600 –> 00:53:41,560

that perfection is to go all the way back to your laser beam and start fiddling.

481

00:53:41,680 –> 00:53:52,050

Let me just loosen the laser beam off and you’ll see that look, I can move the beam by adjusting the laser tube, but hey,

482

00:53:52,270 –> 00:54:00,940

that’s a nightmare, because as soon as you start adjusting your laser tube, you start adjusting everything else that you’ve just set up.

483

00:54:01,780 –> 00:54:08,200

So you’ve got to go all the way around the houses again to try and get the perfection that you’re looking for.

484

00:54:08,980 –> 00:54:12,250

But we’ve got two ways of correcting the error that’s on there.

485

00:54:13,240 –> 00:54:18,430

First of all, we’ve got to move it in that direction there, which is a Y direction.

486

00:54:18,670 –> 00:54:30,520

I pointed out to you before that I made my y axis adjustable, so it’s very easy for me to now adjust my y axis.

487

00:54:33,000 –> 00:54:39,480

To get rid of the error. I’ve made my Y-axis accurately adjustable, so I’ve got rid of the wire.

488

00:54:40,680 –> 00:54:47,910

This is. It happens. It’s pretty good in the other axes, which is, if you like, the x axis.

489

00:54:48,480 –> 00:54:57,720

But if it wasn’t, then I’ve got another form of adjustment to adjusting screws which allow me to adjust the height,

490

00:54:58,770 –> 00:55:02,100

the up down the z axis position of the head.

491

00:55:02,130 –> 00:55:10,950

As I move it up and down, I can move the position of the beam. So as you can see, I can adjust the height of that to bring the x axis onto centerline.

492

00:55:11,580 –> 00:55:16,240

And then as you can see at the bottom position, the beam is passing right through the crosshair.

493

00:55:16,830 –> 00:55:25,260

So we’ve set this up now so that the beam is passing down here and passing cleanly through the axis of the lens,

494

00:55:25,560 –> 00:55:30,390

which you get an upright cut with all the modifications that I’ve made to my machines,

495

00:55:30,780 –> 00:55:35,580

like linking the laser tube and mirror one together on a base frame,

496

00:55:36,060 –> 00:55:44,400

making the Y adjust all relative to the head and making the head adjust all up and down.

497

00:55:44,400 –> 00:55:49,590

So I catch the beam on this mirror. I catch the beam on this mirror.

498

00:55:50,190 –> 00:55:54,750

I don’t try to steer the beam by fiddling around with the laser beam.

499

00:55:55,170 –> 00:56:03,420

My machines have been like this for the past five or six years because I found out a long time ago the Chinese design was just unworkable.

500

00:56:03,690 –> 00:56:10,320

I notice as time has gone on, there are one or two machines out there now that have got adjustable seats.

501

00:56:10,740 –> 00:56:16,500

I mean, there may be one or two that have linked their tubes and mirror one together.

502

00:56:16,890 –> 00:56:25,170

This is a rarity. So you will find your machine is probably let me be crude and say an [INAUDIBLE] to set up.

503

00:56:25,710 –> 00:56:31,200

But you understand the principles now and you may wish to go forward and modify your machine

504

00:56:31,500 –> 00:56:37,590

to deal with some of the issues that I’ve demonstrated in this very interesting little up.

505

00:56:38,040 –> 00:56:40,559

It’s served its purpose extremely well.

506

00:56:40,560 –> 00:56:48,660

Even though it can’t do everything that a machine can do, it’s demonstrated to an immense degree how you have to set your machine up.

507

00:56:49,050 –> 00:56:52,680

So thank you for your time and good luck with your beam setting.

What Next?

Did you enjoy this post? Why not check out some of our other posts:

Disclaimer

Last updated April 25, 2024

WEBSITE DISCLAIMER

The information provided by n-Deavor Limited, trading as Laseruser.com (“we,” “us” , or “our”) on (the “Site”) is for general informational purposes only. All information on the Site is provided in good faith, however we make no representation or warranty of any kind, express or implied, regarding the accuracy, adequacy, validity, reliability, availability or completeness of any information on the Site.

UNDER NO CIRCUMSTANCE SHALL WE HAVE ANY LIABILITY TO YOU FOR ANY LOSS OR DAMAGE OF ANY KIND INCURRED AS A RESULT OF THE USE OF THE SITE OR RELIANCE ON ANY INFORMATION PROVIDED ON THE SITE. YOUR USE OF THE SITE AND YOUR RELIANCE ON ANY INFORMATION ON THE SITE IS SOLELY AT YOUR OWN RISK.

EXTERNAL LINKS DISCLAIMER

The Site may contain (or you may be sent through the Site) links to other websites or content belonging to or originating from third parties or links to websites and features in banners or other advertising. Such external links are not investigated, monitored, or checked for accuracy, adequacy, validity, reliability, availability or completeness by us.

WE DO NOT WARRANT, ENDORSE, GUARANTEE, OR ASSUME RESPONSIBILITY FOR THE ACCURACY OR RELIABILITY OF ANY INFORMATION OFFERED BY THIRD-PARTY WEBSITES LINKED THROUGH THE SITE OR ANY WEBSITE OR FEATURE LINKED IN ANY BANNER OR OTHER ADVERTISING.

WE WILL NOT BE A PARTY TO OR IN ANY WAY BE RESPONSIBLE FOR MONITORING ANY TRANSACTION BETWEEN YOU AND THIRD-PARTY PROVIDERS OF PRODUCTS OR SERVICES.

AFFILIATES DISCLAIMER

The Site may contain links to affiliate websites, and we receive an affiliate commission for any purchases made by you on the affiliate website using such links. Our affiliates include the following:

- makeCNC who provide Downloadable Patterns, Software, Hardware and other content for Laser Cutters, CNC Routers, Plasma, WaterJets, CNC Milling Machines, and other Robotic Tools. They also provide Pattern Files in PDF format for Scroll Saw Users. They are known for their Friendly and Efficient Customer Service and have a comprehensive back catalogue as well as continually providing New Patterns and Content.

- Cloudray Laser: a world-leading laser parts and solutions provider, has established a whole series of laser product lines, range from CO2 engraving & cutting machine parts, fiber cutting machine parts and laser marking machine parts.