The Fiber Laser Learning Lab Series with Russ Sadler

In this Series, Lotus Laser have lent Russ a MOPA 20 watt fiber laser to “play with”. Although Russ has a moderate understanding of laser technology (his words) and how constant power glass tube systems work, pulsing fiber laser engraving machines are shrouded in a deeper mystery than the glass tube machines.

They have been designed for high speed marking and the technology has been well tried and proven. There are limited “tricks” that the pulsing laser technology can perform. You enter predefined parameters for each marking “trick” you wish the machine to deliver , then stand back in amazement. Most correspondents tell Russ that they have bought their machine direct from China and received a machine and EZCAD software, preloaded with a few default parameters. No other instructions beyond the EZCAD manual are forthcoming.

Russ states “I am neither a teacher or expert in this field so you join me in my learning adventure with the warning that I have a simple but inquisitive mind and will probably make mistakes on my way to discovering the truth. I WILL oversimplify and maybe distort the scientific detail in my quest to build a simple picture of why and how this technology works. I am not trying to reverse engineer anything, just to break through the seemingly impenetrable ‘techno cotton wool’ that surrounds this amazing piece of science.”

Contents

In this session, Russ explains the theory behind light and in particular the coherent laser light. He then goes onto describe how the laser beam interacts with different materials.

Video Resource Files

There are no more resource files associated with this video.

External Resource Links

There are no more external resource links associated with this video.

Transcript for Fiber Laser Engraving: The Mysteries of 1 micron Wavelength Light

Click the “Show More” button to reveal the transcript, and use your browsers Find function to search for specific sections of interest.

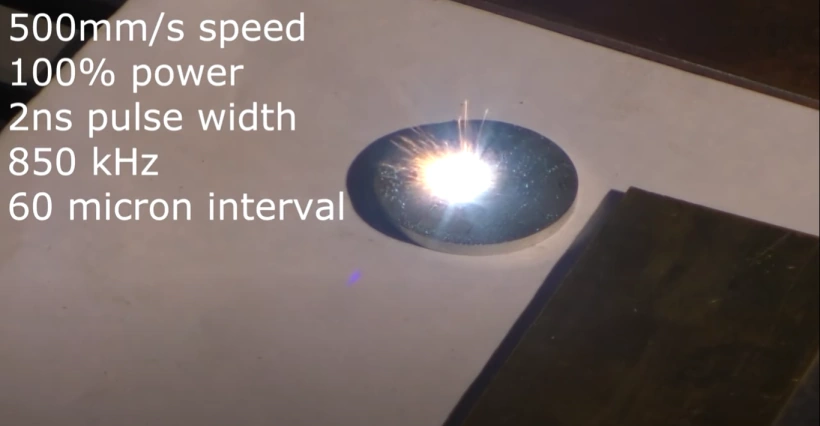

0:01well welcome to another fiber leisa Learning Lab as you can probably see we

0:06know in the workshop today um I’m in my wife’s laboratory well let’s

0:12put it this way she’s on holiday at the moment and she doesn’t know anything about this I’ve got one of her prized

0:19possessions here which is her gin glass and I’ve filled it full of cooking oil

0:26now we’ll come up to this in a minute but today’s session is all about light

0:33this is the stuff that we’re firing at our materials the laser is a beam of

0:40light and I’ve told you that many times before but the light is in a special form first of all all the light

0:46particles are traveling together which makes it a coherent beam they’re all of the same color which makes it

0:52monochromatic those are the two definitions of a laser beam a beam of energy which when it hits a surface can

1:00interact with that surface in one of several ways one of the first ways is it

1:06can be reflected in which case that material is great for making mirrors in the second instance the light can

1:14actually pass right through the material and such materials are great for making

1:20lenses and then there’s everything else

1:25now everything else will absorb energy to a greater or lesser extent I’m using

1:31the word absorbed that’s really the wrong way to describe the way that light

1:37interacts with the material when the light hits the material it has energy just like a stone falling out of the sky

1:46it’s completely harmless it has energy but you have no idea that he has energy

1:51until it hit you on the head and then you can feel the energy that that stone had there’s an energy conversion from

1:58kinetic energy into something that has damaged your head the same applies the light only when it hits the surface does

Transcript for Fiber Laser Engraving: The Mysteries of 1 micron Wavelength Light (Cont…)

2:06it become converted into something else and are converting into something else

2:11as heat I’ve got some very crude models of atoms now these these little plastic

2:16pieces that I’ve got between those atoms and these are different atoms and they

2:22they will each have a different length and a different strength that bond between the relative atoms and they will

2:30stay certain distances apart so this is not untypical of a molecule but as you can see it’s

2:36quite a floppy molecule okay it was it

2:42wobbles nicely at that frequency now if

2:49I take this molecule which is typical of water one H and two O’s h2o yeah it is a

2:59little bit wobbly but it’s not as this one at that frequency this one who knows

3:08what that is that’s very very stiff it’s got very short stiff connections between

3:13the atoms that one is going to be very difficult to make it vibrate here we’ve

3:20got Tigers look they’re bonded in such a way that they’ve been virtually impossible at that frequency to move

3:27here we’ve got yet another one this is an invention of mine I think but you know who knows maybe Ribena

3:34looks like that now this is the electromagnetic spectrum which is covering anything from what we see in

3:42the middle here this is the color range that our eyes can see because our eyes are sensitive to this particular

3:48vibration this particular wavelength of light and the light hitting our eyeball

3:54stimulates the molecules in the back of our eye in different ways different frequencies so that we can see all these

Transcript for Fiber Laser Engraving: The Mysteries of 1 micron Wavelength Light (Cont…)

4:01different colors now this picture here gives us an impression of the different wavelengths of light as we’re up here at

4:08the radio end of the spectrum we’ve got very long wavelengths we can sit by our radio we don’t get any physical damage

4:15apart maybe four ears if we have a two layer and then we get to our microwave well I

4:21don’t think I’d want to put my hand in a microwave here we’ve got infrared which is basically heat and then we’ve got

4:29ultraviolet which is sunburn then we’ve got x-rays which are

4:34dangerous if you put too many of those into your body and then we’ve got gamma rays which are pretty dangerous if you

4:42want to go into space and get frayed and these are all types of light and the way

4:48that I’ve described them um describing the way that the light effects us our skin our molecules in our body now not

4:56everything is going to work the same way as our body I mean if I fire gamma rays

5:02at water I don’t know what happens but it certainly won’t be the same it won’t cause the same amount of damage to water

5:09as it will do to us when you’ve got a molecule which is made up of different

5:14atoms and they’re all joined together like this with various types of bonding

5:22this molecule has a certain what we call resonant frequency I have spoken before

5:28about the definition of temperature everything you see when you look around

5:34you might look solid first of all it’s like this and it’s mainly nothing and

5:42secondly it’s not as you can see stable sitting here doing nothing

5:48even the even the molecules in this paper are busy doing this they’re

5:53vibrating there is something in this universe called absolute zero minus 273

Transcript for Fiber Laser Engraving: The Mysteries of 1 micron Wavelength Light (Cont…)

6:00degrees C and that minus 273 degrees C

6:05everything stops all molecular motion ceases so therefore as you start raising

6:12the temperature up towards room temperature the vibration of molecules

6:18gradually increases and so therefore at room temperature a molecule might be

6:24doing this if we raise it up to a thousand degrees C it’s doing that

6:30it’s vibrating a lot more so that the amount of vibration in a molecule is a

6:36measure of its temperature so when we turn that on its head and say if we can

6:42fire light at this molecule and make it vibrate faster we’re actually going to

6:49make it hotter and that is the principle by which our laser machine works with

6:54firing light at molecules and making them vibrate more and because look we’ve

7:00got all these different shapes of molecules do and do not vibrate as easily I mean for instance this one may

7:08vibrate at a completely different frequency because it’s a very stiff mechanism this one vibrates mm

7:16reasonably okay at moderate vibrations something like this vibrates a lot at

7:24very low frequency you start making this go at high frequency and it will vibrate but it won’t vibrate very much now I

7:32hope I’m going to be able to give you a demonstration of the way in which

7:37different frequencies of and I’m going to have to use mechanical frequencies as

7:42opposed to light frequencies to convert this whole idea back into something that you can see you can hear that low

7:50frequency and you can see the patterns developing on the surface of the

7:55material relatively low frequency we’re getting quite a lot of movement in that

Transcript for Fiber Laser Engraving: The Mysteries of 1 micron Wavelength Light (Cont…)

8:02oil even higher frequency

8:10and we now to a point where we virtually got no movement at all now I’m purposely

8:23not taking the glass down very low because in case you think that it’s all to do with the the vibration off the

8:30side of the glass but it is that movement that’s inducing the waves into here that’s why I’m trying to keep the

8:36the level in this sort of area here where roughly the vibration of the side

8:42is about the same what I’m trying to show you is that the density of that fluid is such that it will only

8:50basically accept waves of a certain frequency no that’s not gin in there

8:55that’s just ordinary water so yes I’ve

9:01washed the glass out and hopefully my wife will never notice the taste of the soap or the oil we’re gonna do the same

9:06thing again we’ve got a much less viscous fluid which moves around a lot

9:13easier I suppose technically it’s a bit like this one it moves around a lot

9:19easier and this time I’m letting you look down on top of glass because it’s

9:25so much easier to see what’s going on now I’m holding the stem so that I don’t get vibrations up through the stem

9:31itself but look you can see how much more energy has been absorbed by the

9:37water this time it’s going into pretty serious vibration okay so that’s really

9:46that high frequency [Music] and you’ll see that water still reacts

9:54quite violently even at high frequency we’re still got our wave around the

Transcript for Fiber Laser Engraving: The Mysteries of 1 micron Wavelength Light (Cont…)

10:01outside and we’ve got lots of surface disturbance as well water has a very

10:08wide range of frequency absorption capability

10:14whereas oil does not and I’m using this very crude analogue to try and indicate

10:21to you that’s why some materials absorb light and get stimulated by it the

10:27molecules are stimulated by certain frequencies of light and they can therefore heat up either the light will

10:34pass through the structure relatively unimpeded because there is a great deal

10:40of nothing in most of the materials that you see around you despite the fact that looking solid the message that I’m

10:46trying to get over to you is that different frequencies of light will have different effects on different molecular

10:53structures certain frequency will stimulate this to a great deal of vibration more vibration means more heat

11:02more heat means that this material will reach a critical point where it will do

11:08something if it was water and it got to 100 degrees C it would turn into steam

11:14if it’s paper and it reaches 250 to 300 degrees C it’ll burst into flame one of

11:21them’s have change and the other one’s a chemical reaction but they’re still based on the fact that you’re reaching you’re stimulating the molecule up to a

11:28certain temperature and once you’ve stimulated the molecule to a critical temperature it cannot exist in that

11:34molecular form it’ll change to something else as we talked about in an earlier session I’ll put that back beside its

11:40cousin the wineglass and provided you don’t split on me she’ll never know any different okay now

11:48here we’ve got five different metals well first of all use something that

11:53we’re familiar with which is stainless steel because we’ve been marking that just recently and I will set that

11:59to take a black mark

Transcript for Fiber Laser Engraving: The Mysteries of 1 micron Wavelength Light (Cont…)

12:14well you see how much energy that was going into that surface this see what

12:21happens when we try it with a piece of brass still quite a lot of power going

12:33into the surface you can hear it and see it a Lavinia

13:01Coppa Wow very very quiet

13:17and finally a piece of mild steel

13:33so I think that probably demonstrate to you that all metals are not the same

13:38they all are absorbing the energy in a completely different way depending on their atomic and molecular structure

13:48well here we are in the daylight so that we can see clearly what’s going on stain

13:55still durable and black which is how I

Transcript for Fiber Laser Engraving: The Mysteries of 1 micron Wavelength Light (Cont…)

14:01set the Machine up mild still not bad I

14:06don’t know why you’d want to mark my oldster because you’ve basically got to paint it it’ll go rusty

14:12not a lot of functional use aluminium

14:17well it looks to be a bit white you can

14:26rub it and it’s sort of turn to dark

14:31gray so I suppose it is a convenient way of marking raw aluminium

14:36yeah well it’s it’s marking the surface

14:41is interesting copper no it looks as though it’s white is it

14:51oh yeah it actually is white that’s a selection of metals let’s try

15:00one or two other things should be okay now I’m not going to change the settings I’m going to leave the metal settings

15:05there which means you know there’s a lot of power there because it can you know it can burn its way into metal so MDF

15:13form all accounts wood products are not affected by one micron wavelength light

15:21so are we expecting this to be cut or not is it wood what is it not wood

15:29there’s wood in it but there’s a binder and the binder is plastic do we think

15:38the plastic is going to burn and the wood not interesting question let’s find

15:43out you let’s press the button and go

15:52well it’s having an attempt it’s got a little bit of spark a little bit of

15:58smoke not exactly doing a lot is it that’s just as a science predictor here

Transcript for Fiber Laser Engraving: The Mysteries of 1 micron Wavelength Light (Cont…)

16:06we got a piece of 10 millimeter thick poplar plywood I think this is a totally

16:11organic material with no man-made materials according to the science this should not have any effect at all you

16:18can see a little teeny-weeny little glitter on the surface there nothing now

16:25we know that glass is not affected because we’ve already tried this in a previous experiment this is what happens

16:31with a co2 laser on the surface we can etch on the surface here’s what happened

16:37when we tried to etch through glass onto a piece of material underneath it went

16:44straight through the glass but the material underneath was aluminium and

16:49because I was touching the aluminium at the time this laid directly on the

16:54surface of the aluminium look we have actually created a mark on the back of the glass it’s a durable work it’s not

17:01going to come off which leaves us thinking about another possibility

17:07although glass transmits looks like a hundred percent of the wavelength of light totally unaffected the material

17:15underneath is not so let’s try this so here what we’ve just marked using

17:21exactly the same settings as this what I’ve done I’ve put a piece of glass over

17:26the top of it this time I’ll do it in the middle so that the glass is sitting nice and flat on the material there

17:46when the aluminium is no longer white it’s um just quite a deep groove

Transcript for Fiber Laser Engraving: The Mysteries of 1 micron Wavelength Light (Cont…)

18:00difficult to say what that is I don’t know whether that’s a metal transfer on

18:06to the back there in other words whether we’ve vaporized the material and deposit it on the glass it certainly looks that

18:13way because now that I’ve scratched the back look I can scratch some of the material off so I’ve definitely

18:20vaporized the material and put it onto the back of the glass but at the same

18:25time I’ve done quite a lot of damage to the back of the glass as well so there must be a quite a large amount of heat

18:31that’s taking place there now some of it has bonded on and some of that I can

18:37scrape off interesting phenomena let’s try the same thing with copper see

18:46we’re getting sparks on top of the glass which is interesting because the surface of the glass is not being damaged Wow

18:53now that is pretty isn’t it

19:00how durable is that I wonder very

19:09durable okay let’s try brass now remember I’m

19:15not changing any of the settings these are all done with the one setting that

19:20we started out with I can see that that

19:28is not going to be whoops I can see that that’s not going to be as durable because as I catch it in the light you

19:33can see you can see the places where it hasn’t bonded properly it’s actually

19:45quite a nice effect I would just lightly clean that with a little industrial scouring pad just very lightly I don’t

19:53damage the glass

Transcript for Fiber Laser Engraving: The Mysteries of 1 micron Wavelength Light (Cont…)

20:02the brass has come up quite nice on this side the copper is perfect we’re now do

20:09stainless steel I suspect this is going to make a bit of a mess because we had a large amount of flamin splurge on this

20:17one if you remember okay

20:26and I have to say that’s a real surprise look at that that is it’s got a lovely silver outline round it but this is the

20:32backside again oh just just lightly scrub over the back of that with this

20:37industrial and break with this abrasive pad it’s certainly durable there’s no

20:43point in trying my oats too because if I if I try and put mild steel on there it’s only gonna go rusty

20:50okay now we’re going to try a completely different group of materials this is I

20:56think a real granite there’s a chance it

21:02might be man-made but I think this one looking at the way the break shows

21:08streaks rather than little spots I think this might be a real piece of granite so

21:16let’s give this a try

21:30well that’s done a pretty durable job of marking that I have to say it’s not bad

21:37at all now I know that this is a piece of manmade marble it’s it’s a quartz

21:45material which has been bound together with a binder of some sort probably an

21:52epoxy binder so we’ll give this a try and see what happens completely

21:59different

Transcript for Fiber Laser Engraving: The Mysteries of 1 micron Wavelength Light (Cont…)

22:06catch it in the light right and there’s just a hint of a mark on the surface maybe with some adjustment we might be

22:12able to get that to a better cut with a different pulse width but that’s not the purpose of this exercise the purpose of

22:18the exercise is to show you that with the same power in the same settings various materials absorb the energy in a

22:26completely different way now this is something I used on the co2 laser and it’s called a laser tile and it’s

22:33specifically designed for I think it’s a bit like a biscuit that’s been cooked first and then that

22:41that’s why it’s got a white glaze on it but then when you are subjected to really intense heat you can actually

22:48bring out the second phase of kiln glazing

23:02well that’s not bad it’s taking the surface off it hasn’t actually done what

23:08the co2 laser does which is to turn the background which is to turn the glaze

23:14black but that again could be just settings because I’ve got a lot of power

23:20going into this and I’ve actually taken the surface off of the glaze and now for

23:25a piece of slate

23:30[Music]

23:36[Music] well that worked just as well as the co2

23:42laser here we’ve got a piece of material called Parapan this is just a color filled acrylic resin now normally it

23:49would go straight through acrylic it’s totally unaffected but because this has got color on it that dye will actually

23:55react with the light and cause a heating effect so let’s give this a try well it

Transcript for Fiber Laser Engraving: The Mysteries of 1 micron Wavelength Light (Cont…)

24:01has left a mark it has just eaten into the surface maybe 10 microns cause the

24:08small amount of discoloration but not impressive but at least it shows that

24:13you can work with acrylic provided it’s got color in it and what we could do we

24:19could just quickly verify that I’ll find a piece of if you watched it watch here carefully you’ll see the height change

24:24when I select the the red mark there we

24:30go so just to assure you that I am changing the focus

24:47he’s doing something there we go it’s done absolutely nothing I have to assume

24:55that this Parapan has got something more than a dying it might have some filler in it as well it doesn’t feel heavy what

25:03else have we got to try well we’ve got this material here which I’m told can be

25:13marked but maybe not at these values but we’ll give it a try

25:18this is polycarbonate

25:33well that was a bit unexpected right so here we are in the daylight to have a

25:38look at this this is quite an interesting effect I mean first of all

25:45it’s turned black which is not what I was expecting but secondly it is raised by probably as much as nearly a

25:55millimeter it’s a very interesting

Transcript for Fiber Laser Engraving: The Mysteries of 1 micron Wavelength Light (Cont…)

26:02effect it’s bubbled up the surface I presume and created extra volume I can imagine

26:10that would be very useful this is a polypropylene cap off the end of a tube

26:15it’s just a piece of plastic cuz I happen to have now I’m always cautious about messing around with plastic

26:21especially soft plastics like this that will melt it’s going I’m fairly

26:26confident it’s going to produce some foams but from previous experience we should be able to watch here in the open because although this is open it’s quite

26:33a nice extractor system here and it’s pulling the area in very nicely and we should see the fumes drawing back I’ve

26:41also had to change the settings for this quite dramatically from those that were used for our first Wow because it was

26:49basically just melting it and I don’t want it to melt as such so now we’ve

26:55gone to 2,000 millimetres a second 100% power we’re still using two nanosecond

27:01pulse width but this time I think we’re using point zero three thirty micron

27:06spacing line pitch [Applause]

27:15so there we go now if you’ve forgotten to mold that into your plastic cap or you want to put your own trademark on it

27:22or something then yeah you can mess around with polypropylene but

27:30it’s not pretty it’s okay a few sessions

27:35ago I did the impossible and engraved on a piece of soft wood I did promise that

27:42an appropriate point in time like now while we’re busy investigating the hold of this subject of materials and how you

27:48mark them and how well they mark that I would bring this up and tell you exactly how I did it it’s both a simple and a

27:56complex process so let me just go through roughly how I got to this stage

Transcript for Fiber Laser Engraving: The Mysteries of 1 micron Wavelength Light (Cont…)

28:02in a previous session you’ve seen me black marking anodized aluminium and at

28:09that time I discovered that one of the chemicals that are used in the sealing

28:16process for anodizing was a material called nickel acetate as I was you as I was

28:24using this material and realized what it was doing it was only skin-deep and that I was converting this nickel

28:30acetate into a nickel oxide which is black I thought to myself hey if I paint

28:38that onto a piece of wood would I be able to do the same with wood that I can

28:44do with anodized aluminium and that’s where the idea came from it took

28:53something like about a month for this stuff to arrive from Poland I bought it on eBay and yeah it was I’ve got I’ve

29:03got about a hundred grams there which cost about fourteen pounds 100 grams is a lot because all I’ve done I’ve mixed

29:10up a very small amount into a solution there we’re gonna paint some of that on

29:16a piece of wood now I wouldn’t advise you get this on your fingers because it

29:22does claim on the packet that it’s both dangerous carcinogenic poisoners

29:29anything else you like to imagine which is dangerous it’s got it

29:36okay so having painted one layer on I’m now going to use my heat gun very

29:45quickly just dry it off and basically force it

29:53into the surface because it’s a fairly open grained wood guess

29:58okay so now the board is warm and damp it’s

Transcript for Fiber Laser Engraving: The Mysteries of 1 micron Wavelength Light (Cont…)

30:06going to take another coat easily just a

30:14thin coat you do the same again

30:23[Music]

30:29and from experience I found that I needed three coats as you can see it’s

30:37not exactly taking a long time to prepare this but it does require the

30:44three coats

30:57[Music] [Applause]

31:03okay so I’m gonna mark that one up as a

31:14now I’m going to take another piece of wood and this time I’m going to put

31:19solution a here we’ve got an a solution which is a different chemical

31:42and we do exactly the same treatment on it I’m going to remark that oops this

31:50chemical bee bee

Transcript for Fiber Laser Engraving: The Mysteries of 1 micron Wavelength Light (Cont…)

32:03then we got one final chemical to try and let’s call that one C and we’ll just

32:10do the same process with this one three coats

32:23now while I was playing with my heat gun I discovered something else and that’s

32:31this if I heat this your material up

32:44you watch very carefully you’ll see the surface beginning to change color

32:50forget about that brown mark on there that’s some residue from somewhere else

33:04just beginning to come in now look I’m scratching the surface

33:17it’s being careful about that

33:25okay suckle but you can probably see

33:34look I’ve just changed the color of the surface that was quite an interesting

33:40discovery because it maybe tells me how and why what we’re going to see is

33:46actually happening the only one of these that I’ve tried before is a and that’s

33:52the one that I demonstrated to you but there’s a good reason why I didn’t want to go ahead and tell you all about a to

33:59start with because excited as I was at finding a I felt there were other

34:05opportunities that were actually better than a when I demonstrated wood

34:10engraving before I had a particular set of settings the motto will see how these

34:17settings work on plain wood

34:24you could say that it is singularly unsuccessful

34:33[Applause] now we try the same settings on the

34:39Scorch side the career

34:49we’ve got a little bit of definition man you can’t see that fugly but I can just say a bit of definition yeah

34:55so let’s think I can improve that

35:05it’s not brilliant but it’s not okay

35:11a little bit further with Mike

35:28and now I thought it was done

35:42more power in there now

35:57right now I’m gonna stop at that point because you can see that it’s a little bit of a fiddly delicate balancing

36:03exercise waste basically what I’ve discovered here is that if you can

36:09remove the cellulose from the surface and basically by heating the surface up

36:15what I’d done was destroyed a lot of the cellulose in the surface and left quite

36:20a lot of the lignin in the wood coming up to the surface there which is what the brown stuff is now by having the

36:28lignin on the surface the lignin actually absorbs some of the light energy and as soon as you can start to

36:34absorb some of the light energy you start going into a burn mode within the wood and as soon as you burn the wood

36:41look what we’ve got here we’ve got carbon and as soon as you got carbon you have like massive absorption of the

36:50light energy it’s very difficult to get a balance between just breaking through

36:55and getting a burn and then like this we’ve got a lot of carbon here if I

37:02don’t let that burn more wicked I could probably burn right the way through this material once we get the burn going it’s

37:09great we’re going to try now the nickel acetate which is the demonstration that

37:15I performed earlier hopefully if this is a consistent process it will work just as well as it

37:22is the first time so here we go

37:34it’s not the strongest player but I could probably get a little bit darker by changing the settings

37:52this is not as dark as these this is

37:57carbon right and it’s out of control this is not carbon this is a

38:03modification of the chemical that I painted into the surface and it only goes as deep as the chemicals penetrated

38:10into the surface so when I change from 80 microns 70 to 60 micron line spacing

38:18in my hatching it doesn’t change the color but my only problem with this is

38:24it’s not a very nice chemical it’s dangerous it’s poisonous and you

38:32couldn’t really paint this onto something and sell it as a product

38:38unless you coated it afterwards with a varnish or something like that so

38:43because it’s a not very nice chemical so I’m not going to advise you use it to

38:48color engrave wood I’ve started to look around for viable alternatives or have

38:55not tested any of these alternatives until now so what we’re going to do now

39:00is first time testing because these are different chemicals that I’ve painted onto the surface in the same way that

39:08all metals are not the same all chemicals are not the same so we shall have to fiddle around to try and get the

39:15best parameter settings if we can find parameter settings at all and we’ll see what we get

39:26[Applause] so side by side that produces the darker

39:31result than this one and they’re both metal salts this one is a sodium salt

39:38and this one is a nickel salt hmm but

39:43this one’s not dangerous because you put that in food that’s baking soda this one

39:49well yeah great idea but I think we’re gonna have to push that down the list now

39:56okay let’s try surface treatment see

Transcript for Fiber Laser Engraving: The Mysteries of 1 micron Wavelength Light (Cont…)

40:13now that was a little fierce I think we

40:19could probably we’ve produced lots of smoke there that we might be able to

40:25tune that one up a little bit that’s the way in which I have discovered we can engrave on wood you need to treat the

40:33surface now there are many other things that we could try like I could wax the surface I could paint the surface with a

40:39spray there are all sorts of other opportunities that you’ve got now that you’ve got the idea

40:46but having seen all the things that I’ve tested what we need to remember is that

40:52when I turn these over and we take a look at the successful results a metal

41:01salt a metal salt a metal salt both of

41:08these are sodium and this one is nickel now there may be other salts that you

41:15could use these two we know to be very safe and the better one of the two turns

41:23out to be the safest one of the lot now

41:28having said safe I would caution I would still make sure you use your extraction

41:35because sodium chloride the chlorine element of it worries me a little bit

41:41I’m not a chemist as I’ve told you many times before so this may well be

41:48producing some nasty chlorine fumes when it gets burnt I shall have to do more

41:55investigation on that and that still leaves us with this one which is a

42:00carbon to sodium carbonate it’s a bicarbonate but it’s still sodium and

42:06carbon this one may eventually be the safest one to use even though this one

42:13may be the best one to use in terms of color density so here are the parameters

42:19for each of these I’m not going to show you the one for the nickel acetate because as I said

42:25I think that that is potentially a dangerous chemical now one further thing before I go that I’ve

42:31almost forgotten to show you MDF okay

42:38now MDF is not a wood it’s not a piece

42:46of material that requires any treatment at all you need to be careful with MDF

42:53when you burn it or cut it as we found out from our co2 laser days because it does produce a formaldehyde gas so you

43:00need to make sure your extraction is good we don’t have to fiddle with too much really nasty debris because we’re

43:07not cutting we’re only just marking the surface but let’s just test it and I’ll

43:14show you what the parameters are

43:32there we go now that is absolutely a superb mark

43:38we don’t need to do anything to the surface of that material at all all you need is the right parameters

43:50now I’ve got a very small block of acrylic here which has happened to be something that I cut out on my co2 laser

43:57because there’s got nice polished edges on it and we’re just going to do this little experiment which I think will

44:02probably be worth looking at closer in future we’ve already seen in this video that you can’t mark clear acrylic in

44:09fact you can’t mark critic acrylic at all unless it’s got some sort of substance inside it which will absorb

44:16the energy so the light passes right through this stuff let’s have a look to

44:22see with again we can do something that would appear to be impossible [Applause]

44:32[Applause]

44:40looking at my black background is not very interesting is it but this might be

44:45more interesting sure it was me that said you can’t do anything with acrylic wasn’t it

45:01first showing the light across the surface there there’s no damage to the surface on either side

45:14all the damages within pretty impressive

45:20hey now the main purpose of today was to show you some of the strange properties

45:26of one micron wavelength light they’re completely different to the properties that we see with the ten point six

45:33micron wavelength light from the co2 laser along the way we’ve seen and

45:40discovered several very interesting processes that we need to investigate a

45:45lot further in the future I’m quite excited about some of the things that we might be able to do with this machine

45:50thank you very much for your time again and I will catch up with you in the next session bye for now