Laser Equipment Shop | Replacement Parts & Accessories for CO₂ & Fibre Lasers

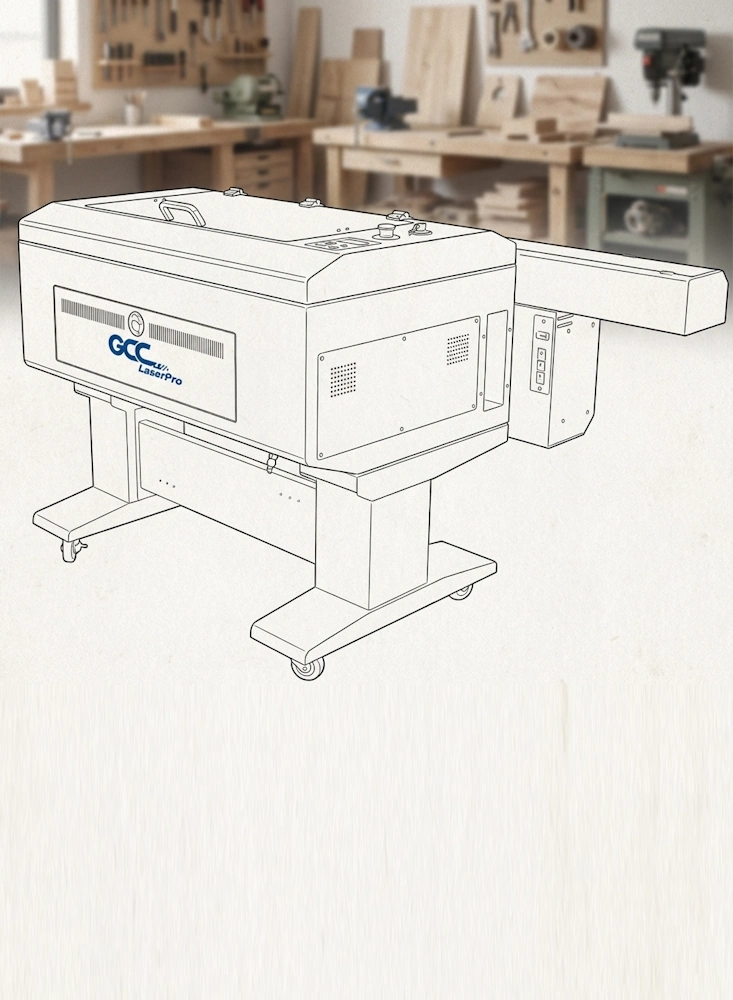

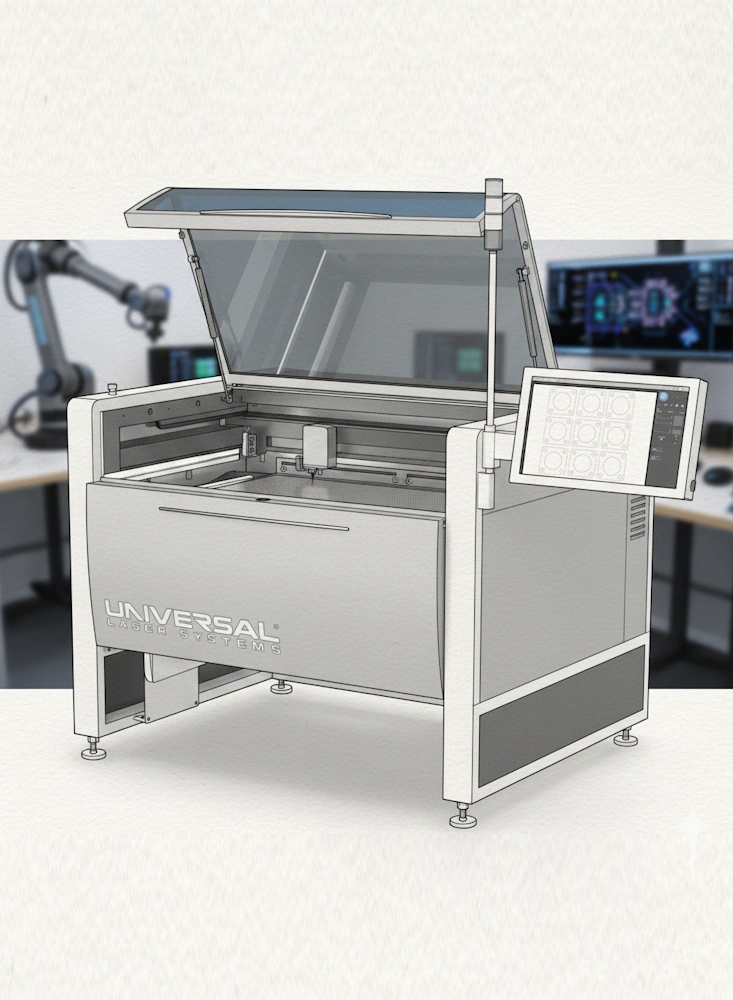

Our Laser Equipment Shop provides high-quality lenses, mirrors, power meters, and OEM-compatible replacement parts for CO₂ and fibre laser systems. The range supports leading machine platforms including Trotec, GCC LaserPro, Epilog, and Universal Laser Systems, as well as Ruida-based Chinese machines widely used in education, workshops, manufacturing, and light-industrial environments.

Every product in the catalogue is selected with a focus on reliability, optical performance, and long-term value in real-world cutting and engraving applications. Whether you are maintaining an existing system, improving cut quality, or upgrading a machine for greater process stability and repeatability, the store offers proven components that integrate easily into common laser architectures.

Typical applications include:

- Replacing worn or contaminated optics to restore cutting consistency

- Changing lens focal lengths to suit different materials and kerf requirements

- Improving beam delivery through higher-quality mirrors and mounts

- Verifying machine output using calibrated laser power measurement tools

- Supporting refurbishment, field service, and workshop-based maintenance activity

Many items are stocked and supplied directly from the UK, while additional product lines are dispatched from our fulfilment hub in China to support wider availability and competitive pricing. Technical support is available for schools, universities, commercial users, and research environments that require guidance on lens selection, machine compatibility, or optical configuration.

Browse the main product categories below to find compatible optics, upgrade components, and service-related accessories for your laser system. If you are working on performance optimisation or upgrading an older platform, the learning resources linked below may also help you understand how lens geometry, beam quality, and system design affect real cutting and engraving results.

For users working in regulated environments or formal workshop settings, further guidance on safe laser operation and optical system maintenance can be found in the HSE guidance on laser safety in the workplace (Optical radiation – including ultraviolet radiation and lasers – Lasers – HSE).

Popular Learning Resources

To support better decision-making around optics, upgrades, and machine performance, the following guides provide engineering-led explanations and practical demonstrations:

- Laser Cutting Myths — The Physics Behind Better Cutting

Evidence-based explanations of common laser cutting and engraving myths, including focal length behaviour, air-assist misconceptions, beam intensity, and real-world CO₂ laser physics. - Diode Lasers Explained — Under the Hood Guide

A deep technical guide to diode laser behaviour, covering optics, modulation, thermal limits, signal timing, and practical engraving performance.

→ - K40 Xtreeem Laser Cutter Upgrade Series

A structured upgrade path for K40-class CO₂ systems, explaining how changes in optics, mechanics, beam alignment, and electronics affect cutting accuracy and repeatability.

Using the right components — alongside accurate physics and measurement — allows laser machines to operate more predictably, with cleaner cuts, tighter tolerances, and improved reliability.

Epilog Laser Compatible Products

Trotec Laser

Laser Mirrors

RF Power Cable for Lasers

Compatible OEM Laser

Laser Power Meters

Laser Lenses

Coherent

GCC Laserpro

Universal Laser Systems

Performance Lens and Nozzle

Synrad