The Concise RDWorks Learning Lab Series

Welcome to Module 4 of the new Concise RDWorks Learning Lab Series with Russ Sadler. Module 4 will build on the information learned in the previous modules and will be targeted on the process of laser cutting. Russ will explain the science behind the laser cutting process and go on to demonstrate the techniques needed to consistently achieve great laser cutting results across a variety of materials. So, Laser Beam Cutting? Where do we start?

In this Session, Russ explains why the current optical lens theory does not apply to laser cutting and explains in detail how the laser actually interacts with materials. He then goes on to explain the importance of intensity within a laser beam and why it has such a huge impact on laser cutting performance. Find out if your laser beam is “BLUNT” or “SHARP”!

Release Date: 11th February 2022

Over the last 6 years, Russ has built up a formidable YouTube following for his RDWorks Learning Lab series which currently has over 200 videos.

The original RDWorks Learning Lab series on his “Sarbar Multimedia” YouTube Channel, follows Russ as he tries to make sense of his new Chinese laser machine and to sort out the truths, half truths and outright misleading information that is available on the web.

Six years later with over 3 million YouTube Views under his belt, Russ has become the go to resource for everything related to the Chinese CO2 laser machine user or wannabe user.

In this new series, Russ has condensed his knowledge and experience of the last 6 years to provide valuable information and insights into the purchasing, understanding, use, repair and maintenance of the Chinese CO2 laser machines and their key component parts.

| Previous Video | Next Video | Series Menu |

Podcast Download for Laser Cutting: Where Do We Start?

You can download the audio file for this video here, just click on the three dots to the right of the player:

Video Resource Files for Laser Cutting: Where Do We Start?

There are no resource files associated with this video.

External Resource Links for Laser Cutting: Where Do We Start?

There are no external resource links associated with this video.

Transcript for Laser Cutting: Where Do We Start?

Click the “Show More” button to reveal the transcript, and use your browsers Find function to search for specific sections of interest.

Transcript for Laser Cutting: Where Do We Start?

1

00:00:06,090 –> 00:00:11,660

The Concise RDWorks Learning Lab with Russ Sadler.

2

00:00:11,660 –> 00:00:16,980

Session 31 Cutting: where do we start?

3

00:00:16,980 –> 00:00:25,890

Well, you’ve seen this before. It’s a lens! You’re very familiar with lenses now because you’ve been using them for all your engraving.

4

00:00:25,890 –> 00:00:31,300

We’re going to change the subject now. Because we’re going to talk about cutting. Now if you

5

00:00:31,300 –> 00:00:37,970

remember, way back in session 18, when we opened up the discussion about engraving.

6

00:00:37,970 –> 00:00:46,470

I said there was no such thing as an engraving lens all lenses are basically cutting lenses.

7

00:00:46,470 –> 00:00:55,130

Well. That is essentially true. But before we get to the lens, we’ve got the laser beam.

8

00:00:55,130 –> 00:01:00,740

It’s a very common term in computer language. Rubbish in equals rubbish out.

9

00:01:00,740 –> 00:01:10,500

Well, it equally applies to this. This is only an amplifying device for intensity, light intensity.

10

00:01:10,500 –> 00:01:14,850

If you put rubbish light intensity in, you’ll get more of it out.

11

00:01:14,850 –> 00:01:19,200

It’ll intensify it, but it won’t intensify it very much.

12

00:01:19,200 –> 00:01:23,430

You get out an amplification of what you put in.

13

00:01:23,430 –> 00:01:32,750

Now everybody knows what lenses do. You’ve seen this picture before back in session eighteen When we introduced you to lenses for engraving.

14

00:01:32,750 –> 00:01:38,220

And you may remember at that point, I said this picture is total rubbish.

15

00:01:38,220 –> 00:01:44,220

This is what the lens manufacturers would have you believe happens.

16

00:01:44,220 –> 00:01:50,220

Well, you’ve already seen that. We don’t need the focal point.

17

00:01:50,220 –> 00:01:57,990

We don’t need the intensity that they talk about here to do engraving. With engraving,

18

00:01:57,990 –> 00:02:02,400

we just want to damage the surface of the material. Most of the time.

Transcript for Laser Cutting: Where Do We Start? (Cont…)

19

00:02:02,400 –> 00:02:07,950

And so consequently, we’re not interested in this very, very fine focal point here.

20

00:02:07,950 –> 00:02:13,350

And the very high intensity that they claim for that focal point. You’ll notice

21

00:02:13,350 –> 00:02:21,150

the cynicism in my voice, because I’ve spent a long time trying to understand how lenses cut.

22

00:02:21,150 –> 00:02:27,420

And lenses do not cut the way that you believe.

23

00:02:27,420 –> 00:02:34,740

Let’s take a look at this one as a classic example look, the rays come in, they hit the focal point,

24

00:02:34,740 –> 00:02:44,840

which happens to be the surface of your material and you get huge intensity of light at that point to do damage to your material.

25

00:02:44,840 –> 00:02:56,540

What then happens to that light? It dissipates. Now you remember when we were trying to find the way to get a soft beam,

26

00:02:56,540 –> 00:03:02,990

that only damaged the surface of the material and did not cut into the surface of the material. We had a lot of trouble.

27

00:03:02,990 –> 00:03:09,760

This was an inch and a half lens that we were using and we had the power turned right down.

28

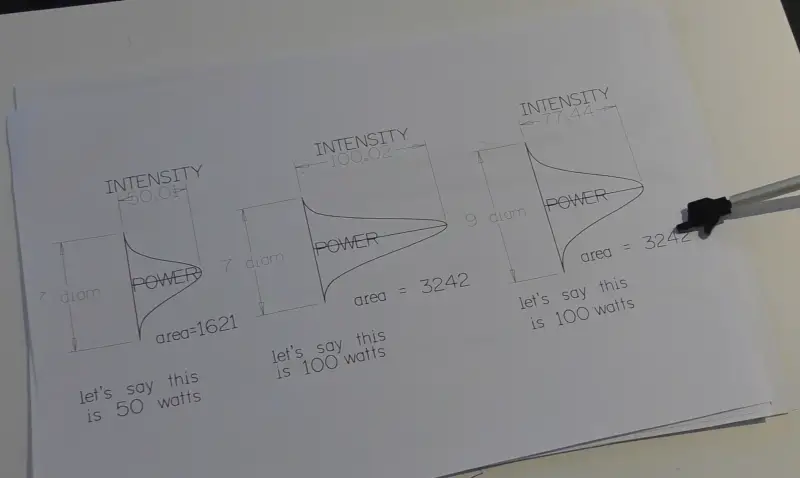

00:03:09,760 –> 00:03:14,770

But we still were penetrating into the surface here with this very deep cut.

29

00:03:14,770 –> 00:03:17,980

I mean, this is somewhere in the region of about two millimeters thick.

30

00:03:17,980 –> 00:03:25,690

This top layer of material on this plywood. When we turned the power up to 100 percent.

31

00:03:25,690 –> 00:03:32,470

That same lens was able to do this amount of damage to the material, it’s gone right through.

32

00:03:32,470 –> 00:03:37,330

Is that the sort of cut that you’d expect after the focal point?

33

00:03:37,330 –> 00:03:46,360

Look what’s happening to the beam after it passes through the focal point. Look, here it is, you can clearly see it comes to zero and then it grows again.

34

00:03:46,360 –> 00:03:51,130

The lens that I used for this job was focused onto the top surface of the material.

35

00:03:51,130 –> 00:03:58,050

So two questions arise; Number one. Why have we got a cut?

36

00:03:58,050 –> 00:04:01,750

And Number two; look at this.

Transcript for Laser Cutting: Where Do We Start? (Cont…)

37

00:04:01,750 –> 00:04:11,200

It’s not just a cut that passes through the material because I’ve increased the power, that should not be possible according to that drawing,

38

00:04:11,200 –> 00:04:15,970

because the intensity is now doing this.

39

00:04:15,970 –> 00:04:24,760

It’s diverging at an alarming rate and there’s no intensity there to actually cut through that material.

40

00:04:24,760 –> 00:04:28,870

Now I’ve approached, learned professors of physics.

41

00:04:28,870 –> 00:04:34,930

I’ve approached senior people in the laser industry that design these machines,

42

00:04:34,930 –> 00:04:42,880

and I’ve approached the lens manufacturers to ask them, can they explain why and how their lenses do this?

43

00:04:42,880 –> 00:04:47,920

As you might expect, the people in the lens industry basically tell me to go away.

44

00:04:47,920 –> 00:04:53,680

What happens after the focal point and how you use and apply the lens is basically your problem.

45

00:04:53,680 –> 00:05:01,240

People in the laser industry and learned professors come up with all sorts of maybes, things like; Well, you know,

46

00:05:01,240 –> 00:05:08,570

once you start producing a gas in here, the laser beam finds its way in somehow and it vaporizes or ionizes

47

00:05:08,570 –> 00:05:13,510

the gas inside there and it gradually finds its way through?

48

00:05:13,510 –> 00:05:18,100

Did you believe that? It sounded like Bullshit to me, to be honest.

49

00:05:18,100 –> 00:05:23,200

So the first thing that we must say is, you must throw away all your conceptions

50

00:05:23,200 –> 00:05:27,970

of how lenses work because they do not work the way that you think they work.

51

00:05:27,970 –> 00:05:32,350

Crude lens theory was around in the time of the Greeks. The Egyptians used it.

52

00:05:32,350 –> 00:05:39,280

Then we get as far as the Middle Ages, where people like Galileo started inventing the telescope and Kepler and people like that.

53

00:05:39,280 –> 00:05:46,390

So this lens theory? Tracing of rays like this.

54

00:05:46,390 –> 00:05:56,200

Look, we’ve got rays, we’ve got rays. That’s the outline of where people think the beam is. Lasers themselves,

Transcript for Laser Cutting: Where Do We Start? (Cont…)

55

00:05:56,200 –> 00:06:06,280

have only been around for about 60 years. Serious industrial application for cutting materials probably only about 30, maybe 35 years.

56

00:06:06,280 –> 00:06:12,280

So this is a very young technology. People that design these laser machines,

57

00:06:12,280 –> 00:06:17,170

they take their technology and put it through something that’s been existing for hundreds of years.

58

00:06:17,170 –> 00:06:20,830

It’s a proven technology. Why would you question it?

59

00:06:20,830 –> 00:06:25,030

Here’s how it works. Well, now I’m afraid it’s your misfortune that

60

00:06:25,030 –> 00:06:30,880

you’ve encountered somebody that does not believe any of this.

61

00:06:30,880 –> 00:06:36,680

Essentially, there’s nothing wrong with the lens theory.

62

00:06:36,680 –> 00:06:42,740

If you had a camera, a telescope, a microscope, a projector.

63

00:06:42,740 –> 00:06:54,920

This stuff works a 100%. It’s well proven, but when you throw a laser beam at a lens, that’s not the same as throwing an image,

64

00:06:54,920 –> 00:06:58,460

which has got fairly uniform light across the image.

65

00:06:58,460 –> 00:07:08,900

No, we’re interested in only one thing; light intensity. Light intensity is the thing that causes material damage.

66

00:07:08,900 –> 00:07:16,340

Remember how material damage happens, you’re busy shaking molecules and the more energy you can put to shake those molecules,

67

00:07:16,340 –> 00:07:27,950

the faster you will be able to create damage. We’ve created damage here, which tells us exactly what the profile of intensity is. Here,

68

00:07:27,950 –> 00:07:37,370

we’ve got a parallel beam which doesn’t really tell us what the profile of the intensity is, but it tells us where the intensity has passed through.

69

00:07:37,370 –> 00:07:44,870

And look, if we look just here, you will see down at the bottom here, we’ve got a hint of this taper.

70

00:07:44,870 –> 00:07:49,670

Yes, we’ve broken through the bottom, but we haven’t broken through with the beam fully.

71

00:07:49,670 –> 00:07:53,060

We’ve still got part of the tapered beam there.

72

00:07:53,060 –> 00:07:59,330

So in the instance of this cut, it’s very interesting to see that we’ve got two different types of material.

Transcript for Laser Cutting: Where Do We Start? (Cont…)

73

00:07:59,330 –> 00:08:02,270

We’ve got material which is this type.

74

00:08:02,270 –> 00:08:09,800

Then we’ve got a softer material, which, if you look, has got a little bit more damage taking place and then we’ve got this harder material again,

75

00:08:09,800 –> 00:08:14,150

and then we’ve got this softer material again, finishing up with the hard material.

76

00:08:14,150 –> 00:08:22,310

And you can see the slight difference in damage as the beam has passed through all of those different material structures.

77

00:08:22,310 –> 00:08:30,230

Now the other observation that I’d like you to make is the whole of this surface here has been cut with the laser beam.

78

00:08:30,230 –> 00:08:37,060

But you notice this is a different colour to this, but it’s all wood.

79

00:08:37,060 –> 00:08:41,140

This happens to be end grain. This happens to be long grain.

80

00:08:41,140 –> 00:08:45,460

So the grains are going in the opposite directions and you can see here, look,

81

00:08:45,460 –> 00:08:51,830

we have got a certain amount of dark brown in certain parts of this grain structure.

82

00:08:51,830 –> 00:08:59,690

But other parts are completely white, and uncharred. I said to you, that engraving was a complicated process.

83

00:08:59,690 –> 00:09:12,500

Cutting is actually simple. But just as complicated in different ways, because then you need to understand much more about the materials themselves,

84

00:09:12,500 –> 00:09:17,270

the damage that you caused to materials when you’re only trying to mark the surface.

85

00:09:17,270 –> 00:09:22,790

You’re not worried about penetration and rate of damage. In fact, if anything, we were trying to do exactly the opposite.

86

00:09:22,790 –> 00:09:29,600

We were trying to minimize the amount of damage that we put onto the surface and just produce this brown scorching.

87

00:09:29,600 –> 00:09:40,140

We found how difficult that was because look, this little cut here, even though it’s done with high intensity light, is not brown.

88

00:09:40,140 –> 00:09:45,930

Remember, we looked inside that and we saw that it was absolutely clean.

89

00:09:45,930 –> 00:09:53,460

What you saw from the top as a black line was, in fact, the occlusion of light, just the fact that it’s a deep groove.

90

00:09:53,460 –> 00:09:59,700

This has got some sort of charring, some sort of carbon surface that’s left behind.

Transcript for Laser Cutting: Where Do We Start? (Cont…)

91

00:09:59,700 –> 00:10:03,870

You can see from my little torch here that I’m shining on the surface.

92

00:10:03,870 –> 00:10:14,190

There is no real edge to that beam. It’s very, very bright in the centre and it sort of tapers away to almost nothing on the edge.

93

00:10:14,190 –> 00:10:19,290

Well, that’s the intensity of the light disappearing towards the edge.

94

00:10:19,290 –> 00:10:23,520

High intensity in the center. Low intensity at the edge.

95

00:10:23,520 –> 00:10:27,390

Well, that’s what that picture shows us.

96

00:10:27,390 –> 00:10:31,920

That’s exactly the situation happening within a laser beam.

97

00:10:31,920 –> 00:10:36,930

The perfect laser beam will have an intensity distribution. As per this curve.

98

00:10:36,930 –> 00:10:41,070

It’s a curve called a Gaussian distribution curve.

99

00:10:41,070 –> 00:10:44,940

Even though the proportions of it might change.

100

00:10:44,940 –> 00:10:51,990

The same mathematical formula is used to generate this curve, regardless of what the shape actually happens to be.

101

00:10:51,990 –> 00:10:57,120

Now what I’ll show you here is a beam that is seven millimeters diameter.

102

00:10:57,120 –> 00:11:05,010

I’ve just chosen some numbers here. They’re just numbers to show the relative differences and what happens within a laser beam.

103

00:11:05,010 –> 00:11:10,590

This curve represents two properties of the laser beam.

104

00:11:10,590 –> 00:11:17,340

On the one hand, the area underneath that curve is its power.

105

00:11:17,340 –> 00:11:25,680

Now, in this instance, we’ve made it 50 watts and the area is 1621 square millimetres under that curve.

106

00:11:25,680 –> 00:11:37,230

So 621 square millimetres represents 50 watts, and that happens to give us a curve, which is a height of 50mm.

107

00:11:37,230 –> 00:11:48,150

Now, if we keep the base dimension of this mathematical formula the same and we change to 100 watts.

108

00:11:48,150 –> 00:11:54,060

Well, if we go from 50 to 100 watch, we expect the area to go up by double.

Transcript for Laser Cutting: Where Do We Start? (Cont…)

109

00:11:54,060 –> 00:12:07,360

And sure enough, here is look 3242. But 3242 area with the same base has caused the curve to change to this shape.

110

00:12:07,360 –> 00:12:13,930

This is a sharper curve, then that one, let’s call that one blunt and this one sharp.

111

00:12:13,930 –> 00:12:24,510

If you buy a 100 watt tube. To replace the existing 50 watt that’s in your machine, you will get twice as much cutting power from it.

112

00:12:24,510 –> 00:12:26,460

Well, sorry, that isn’t the case.

113

00:12:26,460 –> 00:12:36,480

That isn’t the way it works because generally when you buy a more powerful tube, the diameter of the beam increases as well.

114

00:12:36,480 –> 00:12:47,850

And so now we’ve gone from 50 watts to 100 watts, so we’ve still got 3242 as our area.

115

00:12:47,850 –> 00:12:57,540

But because the diameter of the beam has increased. For the same amount of area under there, and you would expect the intensity to double.

116

00:12:57,540 –> 00:13:05,040

It’s only gone from 50 to 77, so it’s only a 50 percent increase in intensity for a doubling of the power.

117

00:13:05,040 –> 00:13:11,820

Now here you’ll see a block of, a little block of acrylic and I’m going to fire the laser beam at this block of acrylic.

118

00:13:11,820 –> 00:13:19,290

Now, just down at the bottom here, you’ll see that I’m blowing some air at where I’m going to fire it, because I don’t want it to catch fire.

119

00:13:19,290 –> 00:13:23,550

But this is about 70 watts of power on a

120

00:13:23,550 –> 00:13:30,620

probably what the manufacturer claims to be a five or six millimetre beam.

121

00:13:30,620 –> 00:13:36,670

Now, if you watch, you’ll see the centre of that beam growing at a much faster rate than the outside.

122

00:13:36,670 –> 00:13:40,400

The Outside is staying virtually the same diameter. And there we go.

123

00:13:40,400 –> 00:13:45,770

Let’s stop there. So that’s the outside diameter of the beam.

124

00:13:45,770 –> 00:13:52,550

And this is the centre of the beam, which has done a lot more damage to the material because of its higher intensity.

125

00:13:52,550 –> 00:13:57,230

This is not a focal point. There is no lens in this system.

126

00:13:57,230 –> 00:14:03,620

The sharp point on this burn is nothing to do with focus.

Transcript for Laser Cutting: Where Do We Start? (Cont…)

127

00:14:03,620 –> 00:14:08,390

It’s all to do with the intensity distribution within the beam itself.

128

00:14:08,390 –> 00:14:14,600

This part of the beam has got a much higher intensity, so it’s burning forward at a faster rate.

129

00:14:14,600 –> 00:14:22,100

This little demonstration is probably the most important demonstration that I can make to try and illustrate how cutting works.

130

00:14:22,100 –> 00:14:30,440

It took 10 seconds roughly for, say, a six millimeter beam to burn through 25 millimeters of acrylic.

131

00:14:30,440 –> 00:14:38,210

Now that’s just a gauge for you. But that is the shape that you’d expect from a cutting beam.

132

00:14:38,210 –> 00:14:46,850

Now I’ve turned the power right down to 15 percent. And here you’ll see what happens for the same 10 seconds of burn.

133

00:14:46,850 –> 00:14:59,270

So you will notice the bubbling that took place in there as the acrylic was boiling and then it vaporizes and turns to acrylic vapor at 200 degrees C.

134

00:14:59,270 –> 00:15:04,470

But look how relatively blunt the beam in.

135

00:15:04,470 –> 00:15:09,450

So there’s the sharp beam at the bottom with its 10 second burn.

136

00:15:09,450 –> 00:15:14,880

As I’ve illustrated here, 10 seconds of burn produces this sharp form.

137

00:15:14,880 –> 00:15:22,740

Here we’ve got a blunt beam because we’ve turned the power right the way down.

138

00:15:22,740 –> 00:15:33,600

OK, so it’s not doing the damage as quickly, so we can get both a sharp beam and a blunt beam out of my tube just by adjusting the power.

139

00:15:33,600 –> 00:15:38,340

We went all the way through a piece of 10 millimetre thick material with this shape of

140

00:15:38,340 –> 00:15:44,700

beam and this shape of beam was doing just the smallest amount of damage on the surface.

141

00:15:44,700 –> 00:15:50,850

The point I want to stress here is that the beam itself is very important to your ability to cut.

142

00:15:50,850 –> 00:15:55,380

Many of the tubes that you buy online are basically junk.

143

00:15:55,380 –> 00:15:59,640

They cannot perform this function here of a sharp beam.

Transcript for Laser Cutting: Where Do We Start? (Cont…)

144

00:15:59,640 –> 00:16:03,870

They will only be able to do something like this, fine for engraving.

145

00:16:03,870 –> 00:16:07,980

No good for cutting. Now this is a gaussian curve, which very conveniently,

146

00:16:07,980 –> 00:16:14,970

I’ve just made six millimetres diameter because look, we’ve got one millimetre, two millimetres, three millimetres either side of the centre line.

147

00:16:14,970 –> 00:16:22,890

The first central two millimeters of the beam contains about 70 percent of the power.

148

00:16:22,890 –> 00:16:30,420

The blue sections around the outside each contain about 10 percent and the remaining five percent each side

149

00:16:30,420 –> 00:16:35,490

here, is the remnant part of the power, right at the extreme edge of the beam.

150

00:16:35,490 –> 00:16:41,700

Power is not the same as intensity when we allow that beam to fire into a piece of

151

00:16:41,700 –> 00:16:47,040

material after one second, two, three, four, five, six, seven, eight, nine, 10 seconds.

152

00:16:47,040 –> 00:16:50,960

This is the shape that we will get, a nice sharp burn.

153

00:16:50,960 –> 00:16:58,500

Now it’s important to remember these three coloured zones. This red zone has got virtually no intensity in it.

154

00:16:58,500 –> 00:17:08,700

The blue zone? Well, it’s got some moderate intensity in it, but the real working zone of your tube is this high intensity part of the tube.

155

00:17:08,700 –> 00:17:14,940

So let’s move our attention away from the beam itself. Remember rubbish in, rubbish out.

156

00:17:14,940 –> 00:17:24,570

This is not rubbish. This is a good quality cutting beam, and we’re now going to talk about what happens when we pass it through this amplifier.

157

00:17:24,570 –> 00:17:27,510

This energy amplifier, which you call a lens.

158

00:17:27,510 –> 00:17:34,620

The most common lens that you’ll come across is something called a plano convex lens. Flat on one side, curved on the other.

159

00:17:34,620 –> 00:17:41,610

The way in which these lenses are designed, is for the light to come in, in a parallel manner.

160

00:17:41,610 –> 00:17:49,230

Parallel to the axis of the lens itself, and pass through the lens to something called the focal point.

161

00:17:49,230 –> 00:17:54,510

You can see that I’m pointing here at something which appears to be the focal point.

162

00:17:54,510 –> 00:18:03,960

But if we look at this a little bit more carefully, what you’ll see is that all the rays are not actually focusing at one single point.

Transcript for Laser Cutting: Where Do We Start? (Cont…)

163

00:18:03,960 –> 00:18:08,070

There is a range of focal points that’s happening here.

164

00:18:08,070 –> 00:18:16,440

It’s manufactured with a spherical surface, and that spherical surface has a property called spherical aberration.

165

00:18:16,440 –> 00:18:23,160

An aberration basically means that it doesn’t all finish up at one fixed focal point.

166

00:18:23,160 –> 00:18:31,060

If we look carefully, you’ll see that these rays from the outside are actually crossing over here.

167

00:18:31,060 –> 00:18:37,110

Whereas, the rays from the centre are crossing over here.

168

00:18:37,110 –> 00:18:44,550

So there’s a difference between the focal points across different diameters of the lens.

169

00:18:44,550 –> 00:18:52,800

So it is incredibly difficult to get a decent single focal point out of a plano

170

00:18:52,800 –> 00:19:02,280

convex lens. If we use the lens the wrong way round and we put our parallel rays of light onto the flat surface of the lens,

171

00:19:02,280 –> 00:19:07,320

aberration becomes absolutely ridiculous.

172

00:19:07,320 –> 00:19:14,370

This is an exaggerated picture. It demonstrates exactly what happens when you flip a lens over. These rays from the

173

00:19:14,370 –> 00:19:20,190

outside focus at an even earlier point than they did when it was used the right way round.

174

00:19:20,190 –> 00:19:25,020

And look at these. Look at the discrepancy between the focal points of all

175

00:19:25,020 –> 00:19:31,050

these various rays that are coming in from these disparate parts of the lens.

176

00:19:31,050 –> 00:19:39,330

And let’s have a look what happens to these red rays from this low intensity region of the beam?

177

00:19:39,330 –> 00:19:45,780

So here are these red rays. And we’ve got another one here.

178

00:19:45,780 –> 00:19:52,130

So there’s our red zone. Hitting the material, there’s not much intensity there.

179

00:19:52,130 –> 00:19:56,240

Let’s take a look at these rays that are coming in from the blue zone.

180

00:19:56,240 –> 00:20:03,650

So there we are. Look, we’ve got our blue zone coming in and it looks as though our blue zone is actually focusing onto the surface.

Transcript for Laser Cutting: Where Do We Start? (Cont…)

181

00:20:03,650 –> 00:20:14,210

It is very small, so we have still only got around about 10 or 15 per cent of the available intensity that we’re applying to that surface there.

182

00:20:14,210 –> 00:20:19,520

Now this yellow zone is not focusing until we get down to here,

183

00:20:19,520 –> 00:20:26,210

and it’s only at that point that we get a true central focus onto the surface in the material.

184

00:20:26,210 –> 00:20:32,450

Most of you guys will be using your lens this way round. You will get moderately good cutting if you use the lens this way round. Because

185

00:20:32,450 –> 00:20:37,640

there is sufficient aberration in here to still create this filtering effect.

186

00:20:37,640 –> 00:20:46,160

Now these learned professors and these lens people don’t happen to have one of these machines tucked away in their shed in their back garden.

187

00:20:46,160 –> 00:20:51,350

So they’ve got no idea of how their lens actually work,

188

00:20:51,350 –> 00:20:59,810

when we ask it to cut material. But my study of the way in which lenses and laser beams work together start to reveal

189

00:20:59,810 –> 00:21:05,360

this strange mechanism, the filtering mechanism that’s caused by lens aberration.

190

00:21:05,360 –> 00:21:13,560

Lens aberration? That’s the last thing that you must talk about when you speak to a lens manufacturer. Aberration is our friend, not our enemy.

191

00:21:13,560 –> 00:21:18,350

Now, as I’ve said, it’s taken me a long time to decode how cutting works.

192

00:21:18,350 –> 00:21:26,750

But one of the interesting stages in that progression was this experiment here that I carried out.

193

00:21:26,750 –> 00:21:36,950

You can see that we’ve got parallel rays of light coming from our laser beam, which has got variable intensity firing at a piece of material.

194

00:21:36,950 –> 00:21:44,810

Now you’ve seen this experiment, 10 seconds fired into that material produced a point at the end of the acrylic block.

195

00:21:44,810 –> 00:21:55,760

There is no lens in that system. That point was all to do with the intensity difference between the outside and the inside centre part of the beam.

196

00:21:55,760 –> 00:22:03,200

Here we’ve got a lens which I’ve put into this system. It was a very, very long, focused lens.

Transcript for Laser Cutting: Where Do We Start? (Cont…)

197

00:22:03,200 –> 00:22:07,490

It started off here at, say, six millimeters diameter,

198

00:22:07,490 –> 00:22:17,450

but at the time it got down to here it was maybe five millimeters diameter because the lens had already started to decrease the diameter of the beam.

199

00:22:17,450 –> 00:22:21,320

But look, I produced exactly the same sort of pointed burn,

200

00:22:21,320 –> 00:22:31,160

but this time it only took three seconds to pass through the 25mm block, not the 10 seconds that it did before.

201

00:22:31,160 –> 00:22:36,530

And here are those two results. This was the one that took 10 seconds.

202

00:22:36,530 –> 00:22:39,170

And this is the one that took three seconds.

203

00:22:39,170 –> 00:22:47,240

Now you may or may not be able to see that there is a significant difference in the diameter of this one compared to this one.

204

00:22:47,240 –> 00:22:52,340

A much smaller beam and a higher concentration of intensity.

205

00:22:52,340 –> 00:22:59,840

And that is why we were able to burn through quicker. This is still not focused because the focus is down here.

206

00:22:59,840 –> 00:23:04,010

It’s just a smaller diameter start point.

207

00:23:04,010 –> 00:23:09,740

And that really is the whole essence of what cutting is about.

208

00:23:09,740 –> 00:23:18,770

And then when we change the focus and reduce the diameter of the beam to an even smaller entry wound.

209

00:23:18,770 –> 00:23:25,050

Look how quickly it runs in. And now we move the focal point even closer.

210

00:23:25,050 –> 00:23:31,780

Now you can clearly see the difference in the diameter of the entry points of these beams.

211

00:23:31,780 –> 00:23:38,920

Slow. Faster. Very fast. Okay, now look you can see what we’ve got here.

212

00:23:38,920 –> 00:23:44,190

We’re getting more of a parallel beam.

213

00:23:44,190 –> 00:23:49,440

It’s tapered here, very tapered here. But here we’ve got a parallel beam.

214

00:23:49,440 –> 00:23:57,840

This is beginning to get much closer to what we see with a deep cut, a parallel cut.

Transcript for Laser Cutting: Where Do We Start? (Cont…)

215

00:23:57,840 –> 00:24:07,740

Look what we’ve got at the top here, though. You see, that’s the effect of the blue zone creating a cone at the entry to the cut.

216

00:24:07,740 –> 00:24:11,730

So we got some of our medium power doing damage.

217

00:24:11,730 –> 00:24:20,580

The higher the intensity, the faster the damage can be done. And here is a classic example of that. The speed at which damage is being done,

218

00:24:20,580 –> 00:24:29,370

is all to do with the concentration of that energy by the lens. Decreasing the diameter of the beam through a lens towards

219

00:24:29,370 –> 00:24:38,310

its focal point, gradually reduces the diameter of the beam and increases the intensity at the centre of the beam.

220

00:24:38,310 –> 00:24:47,940

We started off before the lens with this nice Gaussian distribution, we start putting these various intensities of light through the lens,

221

00:24:47,940 –> 00:24:56,190

and all of a sudden we get some sort of strange filtering effect down here, as you can see as we get closer to the focal point.

222

00:24:56,190 –> 00:24:59,340

Now, this is not a focal point of image.

223

00:24:59,340 –> 00:25:08,400

This is a focal point of intensity because we’ve got lots of different intensity focal points sitting in this beam. When we sample across

224

00:25:08,400 –> 00:25:13,740

there, is no longer a nice Gaussian distribution.

225

00:25:13,740 –> 00:25:23,600

Effectively, what we’ve done there, we’ve pushed the yellow up here like this because it’s intensified.

226

00:25:23,600 –> 00:25:28,730

The red beam is out here somewhere.

227

00:25:28,730 –> 00:25:34,400

Virtually useless and the blue beam, we’ve will actually change the shape of that

228

00:25:34,400 –> 00:25:41,270

gaussian intensity to something completely different than what it was when it started out.

229

00:25:41,270 –> 00:25:51,740

We’ve actually intensified the centre part of the beam itself, and we have filtered out or decreased the useless part of the beam.

230

00:25:51,740 –> 00:25:56,570

That’s what this lens has actually done with the aberration effect.

231

00:25:56,570 –> 00:26:00,830

So let’s take a look at what’s actually happening just here.

Transcript for Laser Cutting: Where Do We Start? (Cont…)

232

00:26:00,830 –> 00:26:01,490

Because remember,

233

00:26:01,490 –> 00:26:14,420

the yellow zone is not not just a zone. It is an area where the intensity is gradually going up and up and up towards the centre of the beam.

234

00:26:14,420 –> 00:26:20,270

Like that, so the center of the laser beam is still much, much higher than the edge of the yellow zone.

235

00:26:20,270 –> 00:26:25,430

This is the entry point. This may be only 0.2 of a millimetre diameter.

236

00:26:25,430 –> 00:26:30,680

The beam is coming in here, but this is effectively the intensity zone.

237

00:26:30,680 –> 00:26:35,830

The yellow intensity zone of that beam, which has been grossly amplified.

238

00:26:35,830 –> 00:26:39,830

Now outside this zone, we’ve got our blue zone.

239

00:26:39,830 –> 00:26:44,590

And outside that. We’ve got our red zone. Now our

240

00:26:44,590 –> 00:26:54,460

red zone is going to have no effect on our material because it’s such a low power to start with and it’s diverging and becoming even lower.

241

00:26:54,460 –> 00:27:03,280

So it’s intensity is unimaginably small. It’s never going to exceed the damage threshold of the material. The blue zone,

242

00:27:03,280 –> 00:27:08,830

well, given enough time. It may well have an effect.

243

00:27:08,830 –> 00:27:18,670

But the first effect that’s going to happen. Remember back to the pictures a few moments ago, the smaller we make the entry wound, the faster

244

00:27:18,670 –> 00:27:25,780

the damage will occur. So we’ve decreased this damage zone to very, very small proportions.

245

00:27:25,780 –> 00:27:36,920

So any intensity that happens to exist at that point is going to have a very, very rapid effect at damaging the material.

246

00:27:36,920 –> 00:27:40,290

And so consequently, what we’re going to get, we’re going to get the beam,

247

00:27:40,290 –> 00:27:47,070

which remember has still got a Gaussian distribution because we’ve not messed around with the yellow part of the beam specifically.

248

00:27:47,070 –> 00:27:52,140

That is still going to have a very high intensity path to the centre of that beam.

249

00:27:52,140 –> 00:28:01,590

Which is immediately going to rapidly grow down into and through a piece of material.

Transcript for Laser Cutting: Where Do We Start? (Cont…)

250

00:28:01,590 –> 00:28:12,020

So the only part of the laser beam that is going to have an effect is the bit that can get through the hole that’s made in the material.

251

00:28:12,020 –> 00:28:21,560

So the material is actually going to be a filter for all this other crap that you normally imagine is going to have an effect on your hole.

252

00:28:21,560 –> 00:28:28,670

No, it’s never going to get through the hole. It’s going to be filtered out by the surface of the material itself.

253

00:28:28,670 –> 00:28:35,690

OK, so this beam that you imagine happening below the focal point is never going to get there.

254

00:28:35,690 –> 00:28:43,160

The only thing that’s going to get below the focal point is what gets through the damage hole that you create on the surface.

255

00:28:43,160 –> 00:28:50,530

And the smaller the damage hole, the faster the material will erode.

256

00:28:50,530 –> 00:28:59,170

So this damage, technically this damage could only ever be as big as this beam.

257

00:28:59,170 –> 00:29:05,650

So the front of the beam might be pointed. But actually, if you give it enough time.

258

00:29:05,650 –> 00:29:12,490

The whole of that beam will produce a parallel hole.

259

00:29:12,490 –> 00:29:20,800

And if you stop the beam just before the material has finished, you will see that the front of the beam will still have a small taper on it.

260

00:29:20,800 –> 00:29:27,240

And that’s what we saw when we looked at our piece of, when we looked at the cut passing through our 10 millimetre material.

261

00:29:27,240 –> 00:29:34,260

Just at the bottom of the cut, we could see evidence where the beam had not quite passed through the material.

262

00:29:34,260 –> 00:29:40,510

We needed to give it a few more parts of a second to allow it to pass through cleanly.

263

00:29:40,510 –> 00:29:45,510

Now, by the time, you give it enough time to pass through the material,

264

00:29:45,510 –> 00:29:51,210

what will have happened is, some of this blue will have had an effect at the top here.

265

00:29:51,210 –> 00:29:57,510

Okay. And what will happen is this blue will effectively be doing this.

266

00:29:57,510 –> 00:30:02,930

It will erode. The top of the cut.

Transcript for Laser Cutting: Where Do We Start? (Cont…)

267

00:30:02,930 –> 00:30:11,120

So there’s your cut profile now. It’s a mixture of a little bit of blue beam with a lot of yellow beam,

268

00:30:11,120 –> 00:30:16,670

which has produced a parallel hole as it’s wandered through the material.

269

00:30:16,670 –> 00:30:25,590

So that’s how cutting, that’s what the cutting mechanism is. And your imagination about what’s happening below the focal point…

270

00:30:25,590 –> 00:30:29,160

It’s just totally misleading you.

271

00:30:29,160 –> 00:30:36,030

Now you can go and have a look at a lot of these tests that I’ve carried out, a lot of these experiments on my RDWorks learning lab channel.

272

00:30:36,030 –> 00:30:41,490

Now I carried out lots and lots of tests with lenses to try and establish what was going on.

273

00:30:41,490 –> 00:30:47,610

And one of the tests that I carried out was here. It was, it was basically a, what I call a speed test.

274

00:30:47,610 –> 00:30:57,630

It’s characterizing the beam itself. What we did, we put a thirty eight point one lens correctly focused onto the surface.

275

00:30:57,630 –> 00:31:10,680

And here we’ve got a two millisecond burst of power at 100 percent. Four, six, eight, 10 milliseconds. 12, 14, all the way up to about 30 milliseconds.

276

00:31:10,680 –> 00:31:17,040

As the exposure time was increased, you could see the rate at which the beam was growing.

277

00:31:17,040 –> 00:31:24,090

But if you look carefully, you’ll see that across here. There seems to be almost like a neck.

278

00:31:24,090 –> 00:31:30,780

But we’ve also got this strange ballooning effect which gets greater, more ballooning as time goes on.

279

00:31:30,780 –> 00:31:39,450

This is not uniform intensity, even at 0.2 diameter, and we’ve still got rays that are coming in.

280

00:31:39,450 –> 00:31:47,830

Like this? And like this.

281

00:31:47,830 –> 00:31:52,600

OK, they’re still not absolutely parallel to the axis.

282

00:31:52,600 –> 00:32:01,930

There are rays that are very slightly off axis, and they’re still passing through this 0.2mm diameter entry hole.

Transcript for Laser Cutting: Where Do We Start? (Cont…)

283

00:32:01,930 –> 00:32:09,460

OK, so the bore that’s been left behind by the major part of the yellow beam is being scoured

284

00:32:09,460 –> 00:32:17,890

by some more rays that are able to get into this hole through the entry diameter.

285

00:32:17,890 –> 00:32:28,990

These are rays that are very, very close to the centre and will come down here like this and they will produce a sort of a scouring effect.

286

00:32:28,990 –> 00:32:35,440

Which the more time you allow, the more effect they will have.

287

00:32:35,440 –> 00:32:38,860

Who said cutting was simple? Did I say that earlier on?

288

00:32:38,860 –> 00:32:43,600

That is the way that cutting takes place. That has got nothing to do with your imagination,

289

00:32:43,600 –> 00:32:51,280

which is dragged around in all directions by these pictures that have been out there for many, many years.

290

00:32:51,280 –> 00:32:55,690

These do not take into account the intensity of the beam.

291

00:32:55,690 –> 00:33:03,760

These just are rays and as I have shown you, these rays are totally ineffective.

292

00:33:03,760 –> 00:33:09,310

They don’t do anything at all. The only bit that works is the central part of the beam.

293

00:33:09,310 –> 00:33:13,420

Now it took me a long time to work out how lenses work,

294

00:33:13,420 –> 00:33:20,770

and I spent a great deal of time doing tests with lenses to try and reverse engineer what was happening to the beam.

295

00:33:20,770 –> 00:33:25,850

Acrylic is a fantastic material that leaves footprints in the sand.

296

00:33:25,850 –> 00:33:30,230

Can I read those footprints in the sand and find out what’s actually happening?

297

00:33:30,230 –> 00:33:35,690

Well, the answer is finally, yes. And I’ve tried to describe that process in this session.

298

00:33:35,690 –> 00:33:44,550

All the test data that I’ve collected about various types of lenses are included in this very, very long PDF document.

299

00:33:44,550 –> 00:33:53,000

It’s 109 pages long. Now, that isn’t 109 pages of reading, because although there’s a little bit of text there, we’ve got summary graphs.

300

00:33:53,000 –> 00:34:01,490

So we’ve got a whole range of lenses, a whole range of different set up configurations that I’ve used for the following tests.

Transcript for Laser Cutting: Where Do We Start? (Cont…)

301

00:34:01,490 –> 00:34:08,480

Now, although, as you can see from the crosses, it’s a pretty comprehensive spread of testing for lenses.

302

00:34:08,480 –> 00:34:15,290

Not every lens is in there. Now, as I pointed out to you earlier on, there is no such thing as a focal point.

303

00:34:15,290 –> 00:34:21,390

The focal point depends on the speed. It depends on the power and one of the things that surprises people.

304

00:34:21,390 –> 00:34:28,100

It also depends on material. So we’ve got a whole range of material here and a whole range of different focal

305

00:34:28,100 –> 00:34:32,720

points that happen to have the best focal points for different materials.

306

00:34:32,720 –> 00:34:42,440

OK, now it clearly says in this that these are tests using acrylic. Now acrylic cuts fairly slowly.

307

00:34:42,440 –> 00:34:51,890

If you want to cut MDF or HDF, the speeds are about the same as the speeds that acrylic cuts at.

308

00:34:51,890 –> 00:34:58,520

The only other materials that you can really cut are organic materials, which are the woods, the real woods, not the plastics.

309

00:34:58,520 –> 00:35:03,890

So real wood will cut at about twice the speed of acrylic.

310

00:35:03,890 –> 00:35:07,610

This one, which is a gallium arsenide meniscus lens.

311

00:35:07,610 –> 00:35:14,320

It takes two four six eight, maybe 10.

312

00:35:14,320 –> 00:35:20,880

And yet when we turn it the wrong way round. Two, four, six eight.

313

00:35:20,880 –> 00:35:32,700

It’s faster. So that’s the sort of information that you can read in this, immense set of data that I’ve produced.

314

00:35:32,700 –> 00:35:39,060

So there’s a huge amount of data that you can find out from this document. Look, here we’ve got a thirty eight point one CVD.

Transcript for Laser Cutting: Where Do We Start? (Cont…)

315

00:35:39,060 –> 00:35:44,010

Look how thin the entry is, it’s deep as well.

316

00:35:44,010 –> 00:35:48,960

So this is a very good lens for cutting deep and producing thin lines.

317

00:35:48,960 –> 00:35:56,600

Because if we take a look here, look, the lines on the surface are bigger, even though the cut is smaller.

318

00:35:56,600 –> 00:36:07,220

All right, so it looks like a thirty eight point one CVD lens has really got the best cut, the deepest cut and the thinnest entry.

319

00:36:07,220 –> 00:36:11,990

So the thinnest line, so you will be able to download this from the website.

320

00:36:11,990 –> 00:36:17,580

Well, that’s as much as I can tell you about cutting at the moment. We’ll get on and do some real cutting in the next session.

Transcript for Laser Cutting: Where Do We Start?

Disclaimer

Last updated August 26, 2021

WEBSITE DISCLAIMER

The information provided by n-Deavor Limited, trading as Laseruser.com (“we,” “us” , or “our”) on (the “Site”) is for general informational purposes only. All information on the Site is provided in good faith, however we make no representation or warranty of any kind, express or implied, regarding the accuracy, adequacy, validity, reliability, availability or completeness of any information on the Site.

UNDER NO CIRCUMSTANCE SHALL WE HAVE ANY LIABILITY TO YOU FOR ANY LOSS OR DAMAGE OF ANY KIND INCURRED AS A RESULT OF THE USE OF THE SITE OR RELIANCE ON ANY INFORMATION PROVIDED ON

THE SITE. YOUR USE OF THE SITE AND YOUR RELIANCE ON ANY INFORMATION ON THE SITE IS SOLELY AT YOUR OWN RISK.

EXTERNAL LINKS DISCLAIMER

The Site may contain (or you may be sent through the Site) links to other websites or content belonging to or originating from third parties or links to websites and features in banners or other advertising. Such external links are not investigated, monitored, or checked for accuracy, adequacy, validity, reliability, availability or completeness by us.

WE DO NOT WARRANT, ENDORSE, GUARANTEE, OR ASSUME RESPONSIBILITY FOR THE ACCURACY OR RELIABILITY OF ANY INFORMATION OFFERED BY THIRD-PARTY WEBSITES LINKED THROUGH THE SITE OR ANY WEBSITE OR FEATURE LINKED IN ANY BANNER OR OTHER ADVERTISING.

WE WILL NOT BE A PARTY TO OR IN ANY WAY BE RESPONSIBLE FOR MONITORING ANY TRANSACTION BETWEEN YOU AND THIRD-PARTY PROVIDERS OF PRODUCTS OR SERVICES.

AFFILIATES DISCLAIMER

The Site may contain links to affiliate websites, and we receive an affiliate commission for any purchases made by you on the affiliate website using such links. Our affiliates include the following:

- makeCNC who provide Downloadable Patterns, Software, Hardware and other content for Laser Cutters, CNC Routers, Plasma, WaterJets, CNC Milling Machines, and other Robotic Tools. They also provide Pattern Files in PDF format for Scroll Saw Users. They are known for their Friendly and Efficient Customer Service and have a comprehensive back catalogue as well as continually providing New Patterns and Content.

- Cloudray Laser: a world-leading laser parts and solutions provider, has established a whole series of laser product lines, range from CO2 engraving & cutting machine parts, fiber cutting machine parts and laser marking machine parts.