The Concise RDWorks Learning Lab Series

Welcome to Module 2 of the new Concise RDWorks Learning Lab Series with Russ Sadler. Module 2 will build on the information learned in Module 1 and will provide practical machine set-up sessions as well as more detailed subject material. So let’s learn all about laser cutting machine parameters and loading files.

In this Session, Russ covers the machine parameters such as calibrating the X and Y axis, machine speed, etc. RDWorks discussed and backing up the machine settings through the Vendor Settings. Individual parameters are explained. User Parameters Settings in the software are explained and backed up. Layer Parameters explained for cutting. Communicating with the laser machine.

Release Date: 12th October 2021

Over the last 6 years, Russ has built up a formidable YouTube following for his RDWorks Learning Lab series which currently has over 200 videos.

The original RDWorks Learning Lab series on his “Sarbar Multimedia” YouTube Channel, follows Russ as he tries to make sense of his new Chinese laser machine and to sort out the truths, half truths and outright misleading information that is available on the web.

Six years later with over 3 million YouTube Views under his belt, Russ has become the go to resource for everything related to the Chinese CO2 laser machine user or wannabe user.

In this new series, Russ has condensed his knowledge and experience of the last 6 years to provide valuable information and insights into the purchasing, understanding, use, repair and maintenance of the Chinese CO2 laser machines and their key component parts.

Podcast Download

You can download the audio file for this video here, just click on the three dots to the right of the player:

Video Resource Files

There are no resource files associated with this video.

External Resource Links

There are no external resource links associated with this video.

Transcript for Laser Cutting Machine Parameters and Loading Files

Click the “Show More” button to reveal the transcript, and use your browsers Find function to search for specific sections of interest.

1

00:00:06,440 –> 00:00:19,150

The Concise RDWorks Learning Lab with Russ Sadler. Session 13: Machine Parameters and Loading Files. Now in the previous session.

2

00:00:19,150 –> 00:00:25,580

We managed to get the machine started and you saw that there was an automatic started routine built into the brain,

3

00:00:25,580 –> 00:00:32,510

into the controller that enabled it to find zero zero for its work area.

4

00:00:32,510 –> 00:00:41,210

Now, there are many other parameters the machine needs to carry out its work, before we even put a program anywhere near the machine,

5

00:00:41,210 –> 00:00:49,340

for example, is 20 millimeters, 20 millimeters of movement on the stepper motors.

6

00:00:49,340 –> 00:00:59,510

Somehow they have to be calibrated so that the stepper motor or the brain knows what our 20 millimeters or two inches or 10 inches looks like.

7

00:00:59,510 –> 00:01:04,910

So we have to make that calibration accurate, how fast are we are allowed to run the stepper motors.

8

00:01:04,910 –> 00:01:10,970

We can’t run them too fast because if we do, the motors will do that horrible noise that we spoke about last time.

9

00:01:10,970 –> 00:01:17,730

Cogging. We should lose steps and steps are most important when you’ve got an open loop system.

10

00:01:17,730 –> 00:01:24,650

Remember that the controller is sending out pulses, but it’s not keeping an eye on what the stepper motor is doing.

11

00:01:24,650 –> 00:01:27,680

All it’s doing is sending signals to the stepper motor.

12

00:01:27,680 –> 00:01:34,190

If we get an interruption because I put my finger in the way, as I showed you last time, everything goes to pot.

13

00:01:34,190 –> 00:01:38,600

There are all sorts of parameters that need to be set in this machine.

14

00:01:38,600 –> 00:01:45,320

And when you receive your machine, those parameters will already be preset by the manufacturer.

15

00:01:45,320 –> 00:01:55,550

One of the things that you must do when you first start your machine up, is to save those manufacturer parameters.

16

00:01:55,550 –> 00:02:00,020

Now, the software that we’re going to talk about later gives an impression that the

Transcript for Laser Cutting Machine Parameters and Loading Files (Cont…)

17

00:02:00,020 –> 00:02:07,550

manufacturer has already saved those parameters into a manufacturer’s parameter file.

18

00:02:07,550 –> 00:02:12,950

I wouldn’t trust that at all, because I’ve known too many people lose the parameters for their machine as

19

00:02:12,950 –> 00:02:20,960

they’re messing around and they preload the factory parameters, only to find their machine is totally junk.

20

00:02:20,960 –> 00:02:26,420

And they have to start from square one and beg, steal and borrow parameter files from somebody else.

21

00:02:26,420 –> 00:02:34,680

So listen to other people’s mistakes and the first thing you must do is what I’m going to show you now.

22

00:02:34,680 –> 00:02:44,610

Now, all Ruide controllers are supplied with a piece of free software called RDWorks, and that’s what I’m running here.

23

00:02:44,610 –> 00:02:48,330

There are other pieces of software which I shall talk about later,

24

00:02:48,330 –> 00:02:54,000

which are probably substantially better than RDWorks, but you have to pay for them.

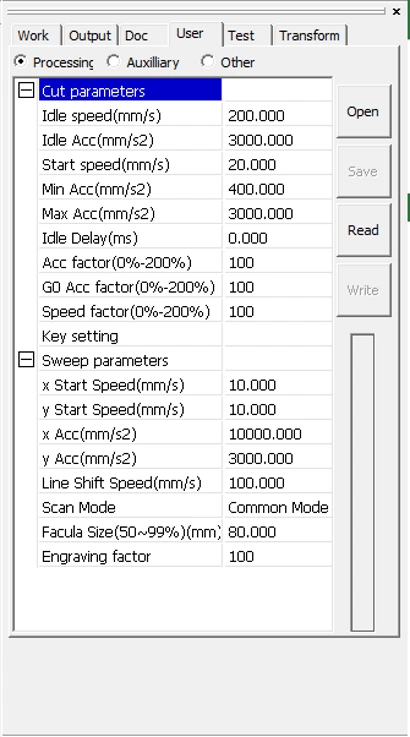

25

00:02:54,000 –> 00:02:59,620

This is free and for free. It’s very good,

26

00:02:59,620 –> 00:03:03,370

but clunky. This software only runs on a Windows machine,

27

00:03:03,370 –> 00:03:10,810

whereas other software’s run on Linux, OS as well as Windows machines, and they’ve got many more features in them.

28

00:03:10,810 –> 00:03:17,120

But we’ll talk about them, a program called Lightburn. Oh, did I say that in a future session.

29

00:03:17,120 –> 00:03:22,780

Now, what Ruida supply on this machine is a digital controller.

30

00:03:22,780 –> 00:03:30,490

There are many other machines around which still use what I call old school type controllers, which are analog controllers.

31

00:03:30,490 –> 00:03:35,890

They do not have anywhere near the power and the flexibility of the digital controllers.

32

00:03:35,890 –> 00:03:36,280

Now Ruida

33

00:03:36,280 –> 00:03:46,540

are not the only people that make digital controllers, but most machines use Ruida controllers because they have become an industry standard.

34

00:03:46,540 –> 00:03:51,860

And as I mentioned just now, this software only runs on Ruida controllers.

35

00:03:51,860 –> 00:04:00,520

So if you have a different controller, it may look similar and it may perform many of the same features, but it won’t be exactly the same as this.

Transcript for Laser Cutting Machine Parameters and Loading Files (Cont…)

36

00:04:00,520 –> 00:04:13,650

The other software that I just mentioned in passing, Lightburn. Is an amazing piece of work, because not only does it run on Windows, Linux and OS,

37

00:04:13,650 –> 00:04:18,750

it encompasses many of the other digital controllers that are out there.

38

00:04:18,750 –> 00:04:24,840

So you can have a standard software that runs all these other digital controllers.

39

00:04:24,840 –> 00:04:29,670

Lightburn is an amazing piece of software, which I said we will get onto at a later date.

40

00:04:29,670 –> 00:04:36,510

But for the time being, I’m going to show you the software that you are probably supplied with, with your machine for free.

41

00:04:36,510 –> 00:04:43,620

I would suggest, in all seriousness, that you use RDWwork’s if it comes with,

42

00:04:43,620 –> 00:04:51,270

if it comes with your machine and you use it for two or three months to find out just how it works,

43

00:04:51,270 –> 00:05:01,410

and then you can download the free version of Lightburn and you’ll see that there’s a completely different universe out there to be experienced.

44

00:05:01,410 –> 00:05:07,330

But become familiar with your machine with this software.

45

00:05:07,330 –> 00:05:15,370

Now, the first thing that I’m going to show you is how to protect your software, not against thieves, but for yourself.

46

00:05:15,370 –> 00:05:22,930

Now up in the top left hand corner here, we shall find file, and down here we shall find vendor settings.

47

00:05:22,930 –> 00:05:29,750

So we click on vendor settings. And the first thing it says is, give me a password.

48

00:05:29,750 –> 00:05:37,420

They didn’t supply you with a password when they supplied this software, but to get into your machine, you need to put in the password.

49

00:05:37,420 –> 00:05:41,380

RD8888. One, two, three, four.

50

00:05:41,380 –> 00:05:49,210

So I’ve got a USB male connector into the laptop and we have a USB male connector into the machine.

51

00:05:49,210 –> 00:05:58,210

And there are two ports on this machine. One of them will say USB or Udisk and the other one will probably say something like disk interface.

Transcript for Laser Cutting Machine Parameters and Loading Files (Cont…)

52

00:05:58,210 –> 00:06:06,110

At this stage the are the RD8888 only sends us to this page in RDWorks.

53

00:06:06,110 –> 00:06:11,110

It’s not talking to the machine at the moment at all. There are several pages that we can scan through.

54

00:06:11,110 –> 00:06:15,100

But before you go anywhere else, what we need to do is to read.

55

00:06:15,100 –> 00:06:22,660

We press the read button and what that’s going to do, it’s going to make this piece of software connect to the machine.

56

00:06:22,660 –> 00:06:27,940

And there we go. You can see that it’s reading in the data and what it’s done.

57

00:06:27,940 –> 00:06:32,920

It’s put the data from the machine into this panel here.

58

00:06:32,920 –> 00:06:38,950

So it tells me all the factors that the manufacturer has put into these panels.

59

00:06:38,950 –> 00:06:43,450

So you’ll have some you have some parameters up here to do with the motor control.

60

00:06:43,450 –> 00:06:50,470

And then you’ll have this thing here, called Breadth. Well, look, this machine is a 600 wide machine.

61

00:06:50,470 –> 00:06:55,180

As I told you before, the machine already knows the size of the table.

62

00:06:55,180 –> 00:07:01,840

What it doesn’t know is where it starts. So here’s the six hundred width of my table there.

63

00:07:01,840 –> 00:07:08,780

And then we’ve got these things here. Look, Jump-Off speed. Well, basically, that’s the speed at which the head will start taking off at.

64

00:07:08,780 –> 00:07:17,680

It can immediately start offf at a speed of 50 millimeters a second and then we’ve got a maximum speed of a thousand millimeters a second.

65

00:07:17,680 –> 00:07:22,600

And then we’ve got acceleration factors here. And then down at the bottom, we’ve got something called keying.

66

00:07:22,600 –> 00:07:27,400

Well, basically, remember the arrow keys that we showed you last time where you can move ahead around?

67

00:07:27,400 –> 00:07:29,440

Well, that’s what these do.

68

00:07:29,440 –> 00:07:38,230

It tells you the jump off speed for keying is only one millimeter a second in this instance, but the acceleration is four thousand five hundred.

69

00:07:38,230 –> 00:07:43,330

OK, so you’ve got the opportunity to change the settings and then we’ve got things like the laser.

70

00:07:43,330 –> 00:07:50,830

Now, the laser is quite important because, you know, in this instance, you can choose glass tube.

71

00:07:50,830 –> 00:07:55,030

Or there’s an RF combination there that you can use.

72

00:07:55,030 –> 00:08:03,220

Well, we’re not using RF on this machine, we’re using glass tube. So there are some settings in here which I’m not going to go through all these settings.

Transcript for Laser Cutting Machine Parameters and Loading Files (Cont…)

73

00:08:03,220 –> 00:08:11,920

And then you’ve got others and soft p.l.c., which is all to do with the red lights, the lamps that you can have on the side of a production machine.

74

00:08:11,920 –> 00:08:15,220

So we’ve got all our settings in there. We can check the X, Y, Z.

75

00:08:15,220 –> 00:08:19,780

This is one of the pre-features I was telling you about, which is the distance calibration.

76

00:08:19,780 –> 00:08:29,890

The distance calibration allows you to set 20 millimeters real dimension to be 20 millimeters of stepper motor movement.

77

00:08:29,890 –> 00:08:35,950

Most of the settings in here are maximum allowable values.

78

00:08:35,950 –> 00:08:41,330

Like you used to say, to your kids, you will be home by 12 o’clock. You set a deadline, you set a limit.

79

00:08:41,330 –> 00:08:44,050

Well, that’s what these are. These are limits.

80

00:08:44,050 –> 00:08:54,160

They’re not necessarily the values that the machine runs at, but these are limits in some instances that are preset for you.

81

00:08:54,160 –> 00:09:04,330

So you can’t exceed safe limits. If we change any of these, we will go back and we will write them back to the machine.

82

00:09:04,330 –> 00:09:09,940

OK, so now we’ve sent those values back to the machine down our USB cable.

83

00:09:09,940 –> 00:09:18,040

That doesn’t make your parameter safe. Remember what we’ve just done? We’ve pulled the parameters up from the machine into this panel.

84

00:09:18,040 –> 00:09:23,950

Now, what we’ve got to do is save them into an external file. You can call it whatever you want.

85

00:09:23,950 –> 00:09:28,180

RussLB21 save parameter success.

86

00:09:28,180 –> 00:09:35,180

OK, just remember where you’ve saved them to, of course, because one of these days you might need to come back in and open them.

87

00:09:35,180 –> 00:09:42,010

It will open them up into here and then you’ll have to write them back to the machine.

88

00:09:42,010 –> 00:09:49,990

And then all of a sudden the parameters that you’ve screwed up will be corrected again to those original ones that were supplied with the machine.

89

00:09:49,990 –> 00:09:57,370

Now, as well as the vendor parameters, up here we’ve got some tabs. And one of those tabs is user.

Transcript for Laser Cutting Machine Parameters and Loading Files (Cont…)

90

00:09:57,370 –> 00:10:02,980

And we’ve got a whole load of parameters in here which are user parameters.

91

00:10:02,980 –> 00:10:10,660

So, for instance, we saw that the maximum speed of X was a thousand millimeters a second.

92

00:10:10,660 –> 00:10:14,200

So let’s have a look in here and see what the maximum speed is.

93

00:10:14,200 –> 00:10:23,110

We’ve got cut parameters, idle speed. Six hundred these settings in here, it says six hundred.

94

00:10:23,110 –> 00:10:33,460

Do I believe that? Let’s read. Now it says five hundred, right, those settings in there with some sort of default.

95

00:10:33,460 –> 00:10:42,190

They weren’t the settings, that are the machine settings. So the machine also stores your user settings as well.

96

00:10:42,190 –> 00:10:50,320

And so you will read your user settings into here and then you will also save them.

97

00:10:50,320 –> 00:10:54,970

OK, if you want to modify them, you write them back to the machine.

98

00:10:54,970 –> 00:10:59,230

But at this point, the one thing that you must do is save them.

99

00:10:59,230 –> 00:11:05,380

And again, you’ll save them to an external file, save parameter success.

100

00:11:05,380 –> 00:11:14,140

That’s the very first message I want to impart to you, the importance of saving the machine parameters that are supplied with your machine.

101

00:11:14,140 –> 00:11:18,460

Remember the menu hiding behind the Z/U button?

102

00:11:18,460 –> 00:11:25,650

There are two things in here. One is called set default parameters.

103

00:11:25,650 –> 00:11:28,530

Set factory parameters.

104

00:11:28,530 –> 00:11:38,250

I would advise you to stay away from those settings because there is no escape from those, once you go into them, you automatically select them.

105

00:11:38,250 –> 00:11:47,100

There isn’t a choice to choose or escape. These parameters here are not quite as dangerous as I’m implying.

106

00:11:47,100 –> 00:11:53,010

They do require a password. I’m not going to tell you the password yet.

107

00:11:53,010 –> 00:11:57,870

I’ve got no intention in this series to show you how to use these pieces of software.

Transcript for Laser Cutting Machine Parameters and Loading Files (Cont…)

108

00:11:57,870 –> 00:12:05,350

I’m going to jump in and out of them and I’m going to do certain things to show you and illustrate what can be done.

109

00:12:05,350 –> 00:12:07,320

But you’re going to have to learn this software on your own.

110

00:12:07,320 –> 00:12:17,910

There is my series, RDWorks Learning Lab on YouTube, which takes you through all the basic commands associated within the first few lessons.

111

00:12:17,910 –> 00:12:22,980

Now, all I’m going to do at the moment is do something very simple. I’m going to draw a square.

112

00:12:22,980 –> 00:12:27,780

OK, so I’ve got myself a 25 millimeter square there. Now I’m going to come up here to the tab

113

00:12:27,780 –> 00:12:32,670

called work. As I said, I’m not trying to teach you how to use this software.

114

00:12:32,670 –> 00:12:40,470

I’m just going to show you one or two key things. Now, at the moment, we’re using this black layer and if we double check on it, click, click.

115

00:12:40,470 –> 00:12:45,090

We’ve got a black layer there. We’ve got a question.

116

00:12:45,090 –> 00:12:49,140

Is output: Yes. And there’s another option in there.

117

00:12:49,140 –> 00:12:56,520

No, we choose Yes. we want the program to go from here down to the machine.

118

00:12:56,520 –> 00:13:01,620

OK, we do want an output for that square because we want to do something with it.

119

00:13:01,620 –> 00:13:09,210

We may possibly have another shape there as well that is on a different layer that we do not want to cut or engrave.

120

00:13:09,210 –> 00:13:14,070

And we can suppress that with the answer: No. Speed?

121

00:13:14,070 –> 00:13:19,230

Well we are we going to make this layer, a cut layer? So 20 millimeters a second.

122

00:13:19,230 –> 00:13:23,400

Yeah. From experience that’s going to do me. If Blowing.

123

00:13:23,400 –> 00:13:27,420

Well, the choices there are, yes or no, to be honest,

124

00:13:27,420 –> 00:13:34,260

it will make no difference to most of your machines because you won’t have the opportunity for being able to turn the air assist on or off,

125

00:13:34,260 –> 00:13:41,580

which is basically what that is. Programable air assist. That’s an advanced feature, which we’ll talk about later.

126

00:13:41,580 –> 00:13:47,410

Processing mode. Well, at the moment it’s set to something called dot, I don’t want dot.

127

00:13:47,410 –> 00:13:51,360

I don’t want to scan. I want to cut. So I’m going to choose cut mode.

128

00:13:51,360 –> 00:13:54,270

Now, automatically, it changes some of the parameters over here

129

00:13:54,270 –> 00:14:00,420

if you note. Let’s just go back to scan mode and you’ll see we get a completely different set of parameters over here.

Transcript for Laser Cutting Machine Parameters and Loading Files (Cont…)

130

00:14:00,420 –> 00:14:05,250

I’ve only got one laser tube in this machine, so forget about the rest.

131

00:14:05,250 –> 00:14:10,470

Even if I put ticks beside all of these, it isn’t going to make any difference because I’ve only got one tube.

132

00:14:10,470 –> 00:14:15,300

These numbers here. You must ignore my numbers because I know what I’m doing.

133

00:14:15,300 –> 00:14:17,430

I’m going to put these at ninety five percent power.

134

00:14:17,430 –> 00:14:25,170

You may well have to use your machine at something like a maximum of maybe 65 or 70 percent power, sometimes 80 percent power.

135

00:14:25,170 –> 00:14:32,430

But there is a limit beyond which you cannot go, which I described to you in the laser tube video.

136

00:14:32,430 –> 00:14:38,910

If you drive the tube with too much current, you will quickly destroy its capability.

137

00:14:38,910 –> 00:14:44,070

You need to find out what the maximum current rating for your tube that the manufacturer allows

138

00:14:44,070 –> 00:14:51,690

and then what the maximum percent power is that matches that current and don’t tick default.

139

00:14:51,690 –> 00:14:56,100

I’ll mention default at a later stage. And in general for cutting.

140

00:14:56,100 –> 00:15:03,840

Keep the numbers exactly the same. There are special situations where you can modify those numbers, but that’s rather advanced stuff.

141

00:15:03,840 –> 00:15:11,870

Anything down here don’t put anything in. Laser through mode: would generally be ticked, untick it, you don’t need it.

142

00:15:11,870 –> 00:15:16,190

So this power here will not have any effect if that power is not ticked.

143

00:15:16,190 –> 00:15:24,170

OK, leave these open and closed delays set to zero so you don’t do anything down here and you don’t tick anything down there.

144

00:15:24,170 –> 00:15:33,080

So now we can say, OK, there are four ways that you can communicate with your machine and tell it that you want to cut that square.

145

00:15:33,080 –> 00:15:36,920

I’m going to show you three of them because I don’t have the fourth one connected up.

146

00:15:36,920 –> 00:15:40,830

The first one is to press this start button here. RDWorks

147

00:15:40,830 –> 00:15:47,750

software will convert your square into a special machine code instructions and it will

148

00:15:47,750 –> 00:15:55,100

send it down the USB line to the machine into a piece of temporary memory in the machine.

Transcript for Laser Cutting Machine Parameters and Loading Files (Cont…)

149

00:15:55,100 –> 00:16:05,760

And then it will automatically run the square and cut it.

150

00:16:05,760 –> 00:16:16,890

Now very crudely, I’m just putting little pulses down and I’m changing the position of the head here to get the smallest dot that I can find,

151

00:16:16,890 –> 00:16:25,440

it’s not far off the correct dimension there. Now this is not the way you’d normally set the focus.

152

00:16:25,440 –> 00:16:32,350

But I’m doing this very quickly and crudely just to show you what’s possible. There we go.

153

00:16:32,350 –> 00:16:37,320

Now, this is really not the right nozzle that I’ve got on here for doing the job.

154

00:16:37,320 –> 00:16:43,350

And you’ll hear that I’ve got some air coming out of the nozzle as well.

155

00:16:43,350 –> 00:16:48,450

Air assist. Again, I’m not going to explain all this technical detail to you at the moment.

156

00:16:48,450 –> 00:16:55,620

Those are for later sessions. All I’m trying to do at the moment is to show you how we get a program down to the machine.

157

00:16:55,620 –> 00:17:00,810

Now, remember, one other thing that comes back to the science that we spoke about in the first sessions.

158

00:17:00,810 –> 00:17:13,020

This stuff reflects. So when I burn through this, I’m going to be firing the laser energy right through the slot at this table.

159

00:17:13,020 –> 00:17:21,600

This table is only about 60 or 70 percent reflective. So it’s going to bounce off this very surface and it’s going to scatter very slightly.

160

00:17:21,600 –> 00:17:28,350

Now, at the moment, I’ve got 10 millimeter spacers under here so that when the light does reflect,

161

00:17:28,350 –> 00:17:34,290

it is going to probably mark the back of the product. It just depends how I’ve got the power set.

162

00:17:34,290 –> 00:17:40,200

If I’ve got the power set just right, then I will just make a cut without too much damage at the back.

163

00:17:40,200 –> 00:17:43,710

If I’ve got too much power, the power will stay on,

164

00:17:43,710 –> 00:17:49,920

it will reflect and it will damage the back of the cut. So we shall see what happens when I do this.

165

00:17:49,920 –> 00:17:55,860

So the first thing I’m going to do on the keyboard is an origin button, and the origin basically means I’m going to start the

166

00:17:55,860 –> 00:18:00,260

head there. And that’s where my shape is going to start.

Transcript for Laser Cutting Machine Parameters and Loading Files (Cont…)

167

00:18:00,260 –> 00:18:05,970

When we look at our program square, you’ll notice that there is a little green dot in the top right hand corner.

168

00:18:05,970 –> 00:18:09,660

That is where the program is going to start from.

169

00:18:09,660 –> 00:18:24,430

I’m not going to put extraction on at the moment. We’re going to produce some smoke. So I’m going to press the start button on the screen here.

170

00:18:24,430 –> 00:18:33,970

OK, look, it’s a cut. It’s cut it out wonderfully well and surprisingly enough, it’s not too bad on the back.

171

00:18:33,970 –> 00:18:41,680

That’s one way that I can get the program to cut. You can see in here it says temp file.

172

00:18:41,680 –> 00:18:45,190

Well, that’s because I’ve loaded that program into a temporary file.

173

00:18:45,190 –> 00:18:53,320

It hasn’t given it a name, but it has temporarily stored that program in the machine in a piece of temporary memory.

174

00:18:53,320 –> 00:18:59,490

So if I want to rerun that again, I can move the head across to there.

175

00:18:59,490 –> 00:19:07,590

With the keypad, with the Arrow keys, I can press origin and you hear it go pip and what that’s done, that’s now made that point

176

00:19:07,590 –> 00:19:14,490

there, the start of a new program. I don’t have to load that same program again,

177

00:19:14,490 –> 00:19:20,550

if I’m not making any changes. I can just do a repeat by pressing the start button here.

178

00:19:20,550 –> 00:19:28,470

And if I press that start button as opposed to the one on the PC screen.

179

00:19:28,470 –> 00:19:40,920

It’ll run exactly the same program again. There’s another way that you can make that program appear on your machine to be cut, and that is to download it.

180

00:19:40,920 –> 00:19:42,000

Now, there was what we’re going to do,

181

00:19:42,000 –> 00:19:49,560

we’re going to use our USB cable and we’re going to physically download the program onto the machine, not into temporary memory,

182

00:19:49,560 –> 00:19:55,230

but into permanent memory this time so that you can use the program again and again and again.

183

00:19:55,230 –> 00:19:59,940

As I’ve just produced there, a one inch, one inch file for cutting to test the cutting speed.

Transcript for Laser Cutting Machine Parameters and Loading Files (Cont…)

184

00:19:59,940 –> 00:20:03,670

Those are the sorts of things that you need to have in your machine,

185

00:20:03,670 –> 00:20:09,900

little test programs that when you want to find the focus or when you want to find a cutting speed for a material,

186

00:20:09,900 –> 00:20:14,910

you can just call up your one inch square and you can fiddle with the parameters on the machine itself,

187

00:20:14,910 –> 00:20:18,930

which I’ll show you how to do in a moment. We’ll go to here this time, I’m going to download it.

188

00:20:18,930 –> 00:20:24,030

Now it’s going to ask me to give it a name. This is a very old operating system.

189

00:20:24,030 –> 00:20:31,570

You can only use eight characters, 25TSQ Test Square.

190

00:20:31,570 –> 00:20:36,550

OK, download success. We press the file button.

191

00:20:36,550 –> 00:20:46,530

And now we shall find a list of programs that are in the machine. Program number 42 says 25TSQ.

192

00:20:46,530 –> 00:20:56,320

And we now select that one, then we’ll press the enter key, there it is, look you can see the square is drawn on there. Now that we’ve got into here.

193

00:20:56,320 –> 00:21:01,330

We’ve got something called frame button here. And I’ll show you what frame button does.

194

00:21:01,330 –> 00:21:10,270

I’ll move the head across, press the origin button and out there, press the frame button.

195

00:21:10,270 –> 00:21:16,740

And there we go, it’s just drawing a quick frame for me to show me where the program will cut.

196

00:21:16,740 –> 00:21:24,170

So I’ll now press the start button on the keypad here.

197

00:21:24,170 –> 00:21:31,040

And it’s now running the same program, but from memory, so I can choose any other program that I want, run it,

198

00:21:31,040 –> 00:21:37,700

and then I can come back to that and run it again. So I could always have that program in memory. When I look at these.

199

00:21:37,700 –> 00:21:49,160

They’re quite nice. Pale brown colour. On the back, not bad, I think I could run that a bit faster. Back to the keyboard, we can press enter.

200

00:21:49,160 –> 00:21:55,350

Bear in mind we’ve got the program there already, Enter, enter.

201

00:21:55,350 –> 00:21:59,880

And now what we get the opportunity to do, is to play with the parameters.

202

00:21:59,880 –> 00:22:06,230

The power is what it is. Ninety five percent. But what I can do is run the job a little bit faster.

Transcript for Laser Cutting Machine Parameters and Loading Files (Cont…)

203

00:22:06,230 –> 00:22:08,390

So if I press the Z/U bitton,

204

00:22:08,390 –> 00:22:22,840

it’ll bring me down to that blue pane there where it says 20 millimeters a second and I can change that to 30 millimeters a second, and press enter, enter.

205

00:22:22,840 –> 00:22:28,760

I’m now ready to run. So I’ve now modified that program to 30 millimeters a second, and that’s what it will be whenever I run it.

206

00:22:28,760 –> 00:22:33,560

It won’t go back to the 20 that I originally sent it down as, it’s now a modified program.

207

00:22:33,560 –> 00:22:38,120

So Origin, checkewith the frame. There we go.

208

00:22:38,120 –> 00:22:46,490

And now we’re running it at 30 millimeters a second. And it still works.

209

00:22:46,490 –> 00:22:52,640

You can see that the one on the right is actually lighter and cleaner than the one on the left,

210

00:22:52,640 –> 00:22:58,040

and that’s just one of the properties of cutting at the right speed. You get less burning on the edge of the cut.

211

00:22:58,040 –> 00:23:02,420

We’ve now found two ways to cut that program.

212

00:23:02,420 –> 00:23:07,520

We can either run it from the PC or we can run it from a program in the machine.

213

00:23:07,520 –> 00:23:12,940

Now, there is a third way. I’m going to disconnect the PC.

214

00:23:12,940 –> 00:23:20,210

I’m now going to show you the third way because in the winter months, this is an unheated workshop and I don’t want to stand in here at

215

00:23:20,210 –> 00:23:28,340

freezing temperatures, programing bits and pieces. So I take my laptop into the warm office and I program my job in the warm office.

216

00:23:28,340 –> 00:23:32,690

I do not have an Internet connection between here and the machine.

217

00:23:32,690 –> 00:23:38,780

You could set up an ethernet connection between the two, but I don’t have that.

218

00:23:38,780 –> 00:23:45,710

So what I can do, I can load my program, instead of via this cable,

219

00:23:45,710 –> 00:23:50,240

I can load it onto a memory stick. So down at the bottom right hand corner.

220

00:23:50,240 –> 00:23:53,840

I’ve got the option here to save Ufile.

221

00:23:53,840 –> 00:23:57,890

Instead of sending the machine code program down the wire to the machine,

Transcript for Laser Cutting Machine Parameters and Loading Files (Cont…)

222

00:23:57,890 –> 00:24:03,830

it’s going to send a machine code program onto a memory stick for me. Save to Ufile.

223

00:24:03,830 –> 00:24:11,570

What do you want to call it? I’m going to save it to the right place, which is a memory stick, which is there.

224

00:24:11,570 –> 00:24:19,550

And then I’m going to save this as 25SQX21to make it different than the file that I’ve already downloaded.

225

00:24:19,550 –> 00:24:25,040

Now when you’ve downloaded it onto the memory stick, it comes up with this gobbledygook.

226

00:24:25,040 –> 00:24:35,460

Who knows what it says. Have a nice day in Chinese I suppose. Anyway, when you see this it basically means you’ve saved the file to your memory stick.

227

00:24:35,460 –> 00:24:42,950

We’ve got two USB ports, this one is the USB wire connection to the PC and this one on top here,

228

00:24:42,950 –> 00:24:49,610

which normally says Udisk disk or USB is the connection into which you put your memory stick.

229

00:24:49,610 –> 00:24:57,920

We now come to the machine again and we can press file button. And what we should find in here is read memory file No.

230

00:24:57,920 –> 00:25:04,250

Second one down is Udisk. So that’s what we want. We want it, because that’s what we’ve plugged in, Udisk.collected you disk.

231

00:25:04,250 –> 00:25:08,990

So we’ll move to Udisk, and press, enter and then we get some more choices.

232

00:25:08,990 –> 00:25:18,980

Read the Udisk file. Well, we’ve got to know what we want to load, so we better read the file. Enter.

233

00:25:18,980 –> 00:25:28,700

And now it tells me all the files that are on that Udisk and the one that we just put on there was no four, 25SQX21.

234

00:25:28,700 –> 00:25:37,510

So we’ll move down to that one and then we get the chance to copy to memory.

235

00:25:37,510 –> 00:25:44,790

Enter. Copy, successful. Enter.

236

00:25:44,790 –> 00:25:51,080

Escape. And now when I go looking for the file on here

237

00:25:51,080 –> 00:25:58,610

Number forty three is 25SQX21, the number of times I’ve run it is zero,

Transcript for Laser Cutting Machine Parameters and Loading Files (Cont…)

238

00:25:58,610 –> 00:26:03,650

so it’s highlighted there so I can press enter and there we go.

239

00:26:03,650 –> 00:26:06,830

Now we’re when I check the parameters this time, remember,

240

00:26:06,830 –> 00:26:14,690

I’ve downloaded the incorrect parameters off of the original PC program. So Enter, Enter and we shall find that

241

00:26:14,690 –> 00:26:17,300

they still say twenty.

242

00:26:17,300 –> 00:26:28,570

OK, so I want to change that so I can now press the Z/U button to move the panel down and we’ll change that this time to forty.

243

00:26:28,570 –> 00:26:35,720

See, I’m extremely daring aren’t I? 40 mm a second, Enter.

244

00:26:35,720 –> 00:26:51,740

Enter. Now, we’re going to run that program at 40 millimeters a second. So we’ll move the head to a new position, there. We’ll press the origin button.

245

00:26:51,740 –> 00:27:07,220

And we just run it from the start key. Forty millimeters a second looked as though it didn’t quite work, it did more or less just look not quite.

246

00:27:07,220 –> 00:27:12,380

So what we can do now, remember, is to edit the program. Enter, Enter.

247

00:27:12,380 –> 00:27:16,920

And we change that to 35. Z/U

248

00:27:16,920 –> 00:27:33,090

Take it down to three, at thirty five millimeters a second, Enter, Enter. Let’s move the head. Press the origin button, press the start button.

249

00:27:33,090 –> 00:27:38,790

Well, it didn’t drop out, but look, it’s actually cut and there we go.

250

00:27:38,790 –> 00:27:46,800

That’s a wonderfully clean cut. Now, I’m just showing you a little bit of a trick there as to how I find the best cutting speed.

251

00:27:46,800 –> 00:27:53,940

Maximum power, and then gradually increase the speed until it doesn’t fall out and then back off a little bit.

252

00:27:53,940 –> 00:28:01,440

And once you get a nice clean cut like that, well, I mustn’t teach you too many tricks, otherwise you become expert too quickly.

Transcript for Laser Cutting Machine Parameters and Loading Files (Cont…)

253

00:28:01,440 –> 00:28:08,980

Now, I want to do one more thing. Remember, we started off at 20 millimeters a second and we’ve now found that we could run at 35.

254

00:28:08,980 –> 00:28:14,400

I’m going to change the speed to 10 millimeters a second, 10 millimeters a second.

255

00:28:14,400 –> 00:28:18,900

Very, very slow, excessively slow for this particular material.

256

00:28:18,900 –> 00:28:24,410

See, the mess that I’m making on the surface and all the smoke coming out underneath.

257

00:28:24,410 –> 00:28:32,450

The burning around the edge. Remember, that is the reflection off of the metal surface underneath, look how bad that is.

258

00:28:32,450 –> 00:28:41,870

That’s the difference between right and wrong cutting. Now, I can reduce that reflection quite considerably by raising the work away from this table.

259

00:28:41,870 –> 00:28:50,540

So if I put it 25 or 30 millimeters above the table, I wouldn’t get anywhere near as much damage as that.

260

00:28:50,540 –> 00:28:52,610

I might get a little bit, but not as much.

261

00:28:52,610 –> 00:29:06,752

With that very simple display of cutting and how we download programs in different ways onto this machine. I think we’ll conclude this session.

Transcript for Laser Cutting Machine Parameters and Loading Files

Disclaimer

Last updated August 26, 2021

WEBSITE DISCLAIMER

The information provided by n-Deavor Limited, trading as Laseruser.com (“we,” “us” , or “our”) on (the “Site”) is for general informational purposes only. All information on the Site is provided in good faith, however we make no representation or warranty of any kind, express or implied, regarding the accuracy, adequacy, validity, reliability, availability or completeness of any information on the Site.

UNDER NO CIRCUMSTANCE SHALL WE HAVE ANY LIABILITY TO YOU FOR ANY LOSS OR DAMAGE OF ANY KIND INCURRED AS A RESULT OF THE USE OF THE SITE OR RELIANCE ON ANY INFORMATION PROVIDED ON

THE SITE. YOUR USE OF THE SITE AND YOUR RELIANCE ON ANY INFORMATION ON THE SITE IS SOLELY AT YOUR OWN RISK.

EXTERNAL LINKS DISCLAIMER

The Site may contain (or you may be sent through the Site) links to other websites or content belonging to or originating from third parties or links to websites and features in banners or other advertising. Such external links are not investigated, monitored, or checked for accuracy, adequacy, validity, reliability, availability or completeness by us.

WE DO NOT WARRANT, ENDORSE, GUARANTEE, OR ASSUME RESPONSIBILITY FOR THE ACCURACY OR RELIABILITY OF ANY INFORMATION OFFERED BY THIRD-PARTY WEBSITES LINKED THROUGH THE SITE OR ANY WEBSITE OR FEATURE LINKED IN ANY BANNER OR OTHER ADVERTISING.

WE WILL NOT BE A PARTY TO OR IN ANY WAY BE RESPONSIBLE FOR MONITORING ANY TRANSACTION BETWEEN YOU AND THIRD-PARTY PROVIDERS OF PRODUCTS OR SERVICES.

AFFILIATES DISCLAIMER

The Site may contain links to affiliate websites, and we receive an affiliate commission for any purchases made by you on the affiliate website using such links. Our affiliates include the following:

- makeCNC who provide Downloadable Patterns, Software, Hardware and other content for Laser Cutters, CNC Routers, Plasma, WaterJets, CNC Milling Machines, and other Robotic Tools. They also provide Pattern Files in PDF format for Scroll Saw Users. They are known for their Friendly and Efficient Customer Service and have a comprehensive back catalogue as well as continually providing New Patterns and Content.

- Cloudray Laser: a world-leading laser parts and solutions provider, has established a whole series of laser product lines, range from CO2 engraving & cutting machine parts, fiber cutting machine parts and laser marking machine parts.