0:00 welcome back to another Rdworks

0:03 Learning Lab today I’ve been distracted

0:06 onto a slightly different subject it’s

0:08 all to do with etching but it’s not real

0:11 edging because we can’t do any edging on

0:14 this machine we can’t cut or scratch the

0:18 surface of metal because there’s just

0:20 not enough power so this is this is

0:23 proper laser etching where you’re able

0:26 to cut into the surface of stainless

0:28 steel but you need a very powerful

0:31 machine to do this now this has been

0:33 done with a nitrogen assist gas which

0:36 means that you get a nice clean finish

0:39 oxygen will burn that surface and make

0:41 it into a black edging now we can’t do

0:44 that on this machine hmm but what we can

0:47 do is a sort of a pseudo etch I’m

0:50 reluctant to call it itching or

0:52 engraving because it’s certainly not

0:53 that what we’re really going to do is to

0:56 paint a substance onto the surface of

0:59 the stainless steel so we’re using the

1:01 heat of the laser and the CNC element of

1:05 the laser to produce the very accurate

1:07 shapes to produce a bonding action

1:10 between the steel and the chemical that

1:12 we’re putting onto the surface so it’s

1:14 not really itching and it’s certainly

1:16 not engraving but at the end result we

1:20 get quite a nice finish now this is just

1:23 a couple of experiments that I did

1:25 earlier just to test out something that

1:28 I had I’ve not done in the test work

1:31 with this product apart from these two

1:33 little test items which I’ve checked

1:35 I’ve done some fairly serious scratching

1:37 on this part here I mean here we’ve got

1:40 a piece of stainless steel

1:49 and as you can see it’s well and truly

1:52 Bandhu on that surface and it isn’t

1:54 going to come off so I don’t think we’ve

1:56 got any problem with durability we’re

1:58 just going to find out now what sort of

1:59 powers that we need and what sort of

Transcript for Laser Marking Metal (Cont…)

2:01 problems we’re going to come across when

2:03 we did carry out this process now told

2:05 my client yes I can get hold of this

2:07 this marketing product it’s not that

2:09 expensive until I start to checking it

2:12 out and what I found was that here in

2:14 the UK a can of this stuff is going to

2:17 cost me over 140 pound that’s $200

2:20 whereas if I bought it in the US with

2:23 shipping and I lived in the US it would

2:26 cost me half that price about $100 so

2:28 still quite an expensive product this

2:30 spray-can product has got some flammable

2:33 chemicals in it and consequently that’s

2:36 part of the reason for this excessive

2:38 cost here it has to be carried as a

2:40 hazardous chemical via an aeroplane so

2:44 shipping costs an arm and a lake to get

2:46 it to the UK it’s still expensive in the

2:49 States because it has to go UPS or

2:51 something like that as a hazardous

2:53 chemical so I checked up I checked up on

2:55 the website and found that they make a

2:57 non hazardous chemical version now which

3:01 is basically a water-based version of

3:03 the same product which you can ship as a

3:06 non hazardous material and this is an LM

3:09 m60 60 after I’d ordered this material I

3:13 did a little bit more research and found

3:16 out from various sources that you can in

3:20 fact achieve nearly the same result a

3:23 much cheaper way this is the cheaper way

3:28 it’s a molybdenum disulfide dry

3:32 lubricant

3:33 this has got some ceramic material in it

3:37 which is why it’s called sir mark but

3:39 having said that a lot of the material

3:42 in this product is molybdenum and of

3:46 course the main product in this is

3:48 molybdenum as well so we stand these

3:53 side-by-side and we find that this one

3:58 even shipped to me now I bought that for

Transcript for Laser Marking Metal (Cont…)

4:01 around about 60 pounds courtesy of a

4:05 friend in the States and I bought this

4:07 of my local eBay for 12 pounds about $17

4:13 for less than a tenth of the price

4:15 I’ve probably got 10 times more material

4:17 here and what we’re going to do today is

4:19 to carry out a comparison test between

4:23 these two products because this is an

4:24 aerosol can we should take a quick look

4:26 at the safety precautions there are no

4:29 specific safety precautions or chemical

4:31 hazards in here apart from those that

4:33 you would normally expect to find on a

4:35 spray can because it’s got a propellant

4:36 in it it has done do not expose to

4:38 temperatures exceeding 50 degrees C may

4:41 cause irritation to skin and eyes

4:43 repeated exposure may cause skin dryness

4:46 and cracking wear suitable gloves okay

4:51 well I’ve now read the very very very

4:55 small print on the bottom of the bottle

4:57 here and decided I ought to probably

5:00 take a few precautions because I’m not

5:03 allowed to swallow it I’m not allowed to

5:05 snort it oh inhale it sorry and I’ve got

5:09 to protect my clothing and I must keep

5:11 it off my skin it could give me lung

5:15 cancer it may affect my liver hmm I’m

5:21 just wondering whether I should even

5:22 open the bottle and this is the safe

5:24 product

5:31 I think it’s all American legislation so

5:35 let’s throw caution to the wind as you

5:44 can see in here this is a very gloopy

5:46 solution which I’ve stirred up now and

5:48 I’ve put a small amount in there and in

5:51 the ratio of about three or four to one

5:54 I’ve put some acetone solution in there

5:57 and given it a jolly good mix up with a

5:59 paintbrush

Transcript for Laser Marking Metal (Cont…)

6:00 now they recommend that you use a foam

6:02 brush rather than a head paint brush but

6:05 I don’t have a foam brush so we have to

6:08 make do with what I’ve got what I’ve

6:09 also done now has laid on a fairly thick

6:13 coating as even as I can with a

6:15 paintbrush it’s not totally even but I’m

6:19 sure it will work and now we’ve got to

6:21 leave that for around about 20 minutes

6:23 half an hour to dry I’m still not dead

6:26 so we put the cap on

6:27 I’m not even dizzy and we’ll put this

6:30 very dangerous chemical away now because

6:32 we painted this surface here with an

6:34 acetone mixture it’s already sort of

6:37 self cleaned itself just in case there’s

6:40 any risk of contamination on this

6:43 surface here I would just make sure I

6:44 clean the surface with acetone and in my

6:52 carefully constructed spray booth which

6:56 will try product number two number two

7:00 just like paint it needs to be well and

7:02 truly shaken because it has it has it

7:05 does settle out so this product is much

7:11 easier to

7:14 apply just a thin coat everywhere okay

7:24 here are the two products now bear in

7:25 mind we mustn’t expose this one to heat

7:27 so it says I’m highly flammable but what

7:33 the hell rules are made to be broken

7:41 and I think you can say at a glance this

7:44 one is already ready to use it’s dry

7:47 this one not yet

7:53 okay that’s more or less drying now and

7:56 so what we’ll do we’ll do it we’ll do it

7:58 the wrong way around will we use this

Transcript for Laser Marking Metal (Cont…)

8:00 one first and this one has now got a

8:03 little bit of heat in the metal so I’ll

8:06 leave that to carry on baking nice and

8:08 dry but that one is I do

8:12 just check the focus on that which i

8:14 think is about right that’s not far out

8:15 and we’ll run a program now I’m going to

8:20 be very careful about throwing the fumes

8:22 outside and we’ll just start the program

8:25 off like this and then unusually for me

8:28 I’m going to close the lid

8:33 so as you can see it’s very unexcited

8:37 even though the fumes are being

8:39 extracted backwards I can still smell

8:41 here just a little bit a strange almost

8:46 like burning matches smell it’s

8:48 something different but it’s that sort

8:50 of smelly get when you strike matches

8:53 when I did my first number two samples

8:56 that you saw I got a bit of a hint of

9:00 this strange smell and I decided that I

9:03 really ought to check out what happens

9:06 when you burn molybdenum because bearing

9:10 in mind this is a molybdenum spray that

9:12 we’re testing at the moment and the

9:14 other product even though it doesn’t say

9:16 on the label when I look at the contents

9:18 of it on the website there’s a fairly

9:21 high molybdenum content and what happens

9:24 is when you heat molybdenum it produces

9:27 something called molybdenum trioxide

9:30 because the molybdenum combines with the

9:32 oxygen that’s in the air now molybdenum

9:35 dye trioxide is actually a hazardous

9:38 substance if I can point you towards the

9:40 New Jersey Department of Health and

9:43 their hazardous substance fact sheet

9:45 about molybdenum trioxide you can see

9:49 for yourself just why I’m being a little

9:51 bit cautious I don’t want to breathe any

9:55 of this stuff because it says it can

9:57 affect you when breathed in eye and skin

Transcript for Laser Marking Metal (Cont…)

10:00 contact can cause irritation the dust or

10:03 mist can irritate the nose throat and

10:04 lungs causing cough and or tightness in

10:07 the chest

10:08 molybdenum trioxide can cause weight

10:10 loss or I could do with some of that

10:12 diarrhea for muscle coordination while

10:15 I’ve already got that headache and

10:18 muscle or joint aching repeated exposure

10:21 can reduce red blood cell count anemia

10:24 and molybdenum trioxide can affect the

10:28 liver and kidneys

10:29 bear in mind whether you’re using the

10:32 cheap or the expensive version of this

10:34 product I urge you to take adequate

10:37 ventilation precautions I know I might

10:40 have joked about the safety aspect of it

10:42 to start with but this part of it is not

10:45 something to be joked about I don’t

10:46 think now I’m going to lift the lid just

10:49 for a moment so we can see what’s going

10:50 on because look at that doing very much

10:53 it’s just burning the bone in the

10:55 chemical off the surface by the look

11:00 now I would suppose it’s fairly

11:02 excusable why there’s no warnings on

11:04 here about burning this product because

11:08 it was never designed to be used in the

11:11 way that we’re using it but I’m not so

11:13 sure about that product I’m fairly sure

11:16 there should be some warnings on there

11:18 but when this product is burnt it could

11:20 produce further have hazardous chemicals

11:23 or gases I’ll leave you to make up your

11:25 own mind we’re yet to find out whether

11:27 or not these two stack up against each

11:29 other this might be cheaper nasty this

11:32 might be expensive and fantastic

11:33 well here’s our end product we’ll just

11:38 get our other panel underway

11:43 so let’s set that panel going now we’ll

11:47 take a a look this is like magic

11:50 painting in Reverse because hopefully

11:52 what this will tell us

11:55 how good various speeds are and feeds

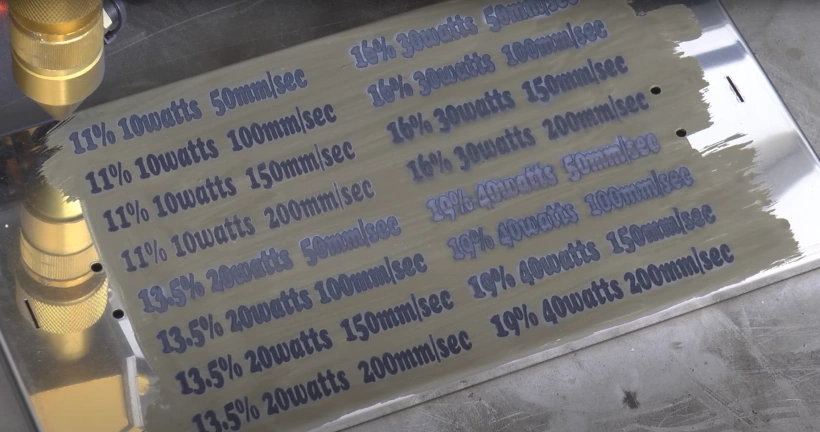

11:59 what you can see on here I’ve got four

Transcript for Laser Marking Metal (Cont…)

12:02 and eleven percent power which is ten

12:04 watts for at 13.5 percent which is 20

12:09 watts for at

12:12 30 watts and for at forty watts

12:17 and each one of these watts I’ve got

12:20 fifty hundred hundred and fifty and two

12:22 hundred millimeters a second so we’ve

12:24 got a good matrix of data here that we

12:28 can play with and this is what I hope I

12:31 should be able to do with it

12:34 with some acetone

12:40 we should be able to get this stuff off

12:43 and then what we should be left with

12:49 for the parameters that work 50

12:51 millimeters a second that one is just

12:54 barely etched into the surface this one

12:57 at 20 watts has marked the surface but

13:01 it’s not very black this one at 30 watts

13:04 has done a good job at 50 millimeters a

13:07 second but once you start getting up to

13:10 100 millimeters a second it’s not very

13:12 good and this one at 40 watts is good as

13:16 well and even at 100 millimetres second

13:19 it’s starting to drop off so whichever

13:21 way you look at it it would appear that

13:23 speed is the controlling factor and that

13:27 makes sense because I’ve got a one and a

13:30 half inch lens on here which has got a

13:33 very powerful hit very powerful amount

13:37 of energy density but provided I keep

13:39 the high energy in one spot for long

13:41 enough it will burn this chemical into

13:43 the surface but as soon as I start

13:45 moving across quickly there’s not enough

13:47 time to build up any heat to burn the

13:50 chemical into the surface so this makes

13:53 perfectly logical sense that we need to

13:55 run at a reasonably medium to high power

13:58 30 40 50 watts but in a fairly slow

Transcript for Laser Marking Metal (Cont…)

14:01 speed that’s an entirely acceptable

14:04 black mark and the end result of our

14:07 expensive product I think we should do

14:09 the same thing again we’ll take it off

14:10 with acetone

14:19 well let’s take them out for a proper

14:21 daylight comparison I think you can see

14:25 you get what you pay for

14:28 there’s obviously a sweet spot here for

14:30 the cheap product which I think you’ll

14:39 agree it’s still very very durable and

14:41 if you get this one at about the right

14:44 speed then yes it works extremely well

14:48 and that was 30 watts 50 millimeters a

14:51 second that was definitely the best one

14:52 because when you start going 40 watts

14:55 for some reason or other there’s not the

14:58 buildup and there’s a bit more

15:04 distortion in the surface this one has

15:08 got a small amount of distortion in the

15:11 surface these have got the same sort of

15:18 thing because we’re running at the same

15:19 speed it’s actually causing a slight

15:21 distortion in this one point two

15:23 millimeter thick stainless whereas in

15:25 fact when we start running a bit faster

15:27 at 30 Watts hundred millimetres a second

15:32 100 millimetres 150 millimetres a second

15:35 that’s still not bad we’re losing it a

15:38 little bit here for some reason over but

15:42 this has got more of a buildup on the

15:43 surface you can see as I’m scratching it

15:45 off but it still leaves a nice mark

15:50 behind even if it scratched off what can

15:52 I say if I had the choice I would

15:56 probably still go for this product here

15:58 because at that sweet spot it gives a

Transcript for Laser Marking Metal (Cont…)

16:01 good result if I have a very delicate

16:04 product to mark then this is undoubtedly

16:08 the right product to go for because look

16:10 with as little as 10 10 watts and 50

16:13 millimeters a second you get a good

16:17 H on the surface without causing any

16:21 distortion to the product in the

16:23 background so with this product we’ve

16:26 only got one good sweet spot whereas

16:31 this one there are quite a few sweet

16:33 spots depending on what thickness of

16:35 material you’re working on but generally

16:37 that one there is the best well I can’t

16:42 tell you any more than that other than

16:43 whichever one of these products you use

16:46 be careful with the ventilation you pays

16:49 your money and you takes your pick thank

16:54 you very much for watching