Although the glass CO2 laser tube used in many laser cutting and engraving machines are classed as consumables. There are a number of ways to prolong the life of the tube and get more “bang for your buck”. So, how to get a longer life from your laser tube? You need to consider a number of factors such as:

- Use a quality brand of laser tube tube. e.g. SPT or EFR

- The maximum current rating for the tube (this must not be exceeded).

- Using a reputable supplier.

- Maintenance of the optical path (cleaning mirrors and lens).

- Effective cooling of the laser tube.

However, even if you get these correct from the start. It will only help towards, not guarantee a long tube life.

Running costs on a laser cutting and engraving machines are relatively low. However, the biggest consumable cost you will be faced with is replacing the laser tube. Get it wrong and you could be looking at replacing tubes every 3 months. With a little bit of planning, preparation and preventative maintenance you can generally prolong the lifespan of your tube significantly. These tips will help guide you to getting a decent tube and then to keep it in peak condition for as long as possible.

9 Tips On How To Get A Longer Life From Your Laser Tube

1. Your First Laser Tube:

If you are buying a new laser cutting and engraving machine, make sure you ask for the make, model number and physical dimensions of the tube supplied with the machine. It is not unusual for machine suppliers to exaggerate the laser power output of a laser tube, promising 50 watts and supplying a 40-watt tube (50 watts is the Max power and 40 Watts is the rated power) for example. I have also heard of instances where a machine was sold as a 100-watt system but actually contained a 60-watt laser tube.

- A quick rule of thumb for the narrow tubes; (50mm / 2″ diameter) is 5 Watts per 100mm of tube length.

- Fat body tubes; (80mm / 3.15″ diameter) are typically 7~8 Watts per 100mm of tube length

2. Laser Brand:

The highest rated Glass CO2 laser tube manufacturer is most probably RECI. Followed by EFR and SPT with honourable mentions to Tongli and Yongli. Just be aware that RECI’s lowest power laser tube is the W1 @ 75 watts. So if you have a 60-watt or lower tube, I would suggest trying to specify EFR or SPT. Making sure you have a recognised brand fitted to your machine will save you time and money in the future.

3. Buying a replacement tube:

In this scenario, it is the supplier that you need to consider carefully. Many people buy directly from China and unfortunately, there are already claims that the RECI tubes are being counterfeited. I have seen reports of people trying to buy EFR tubes and the Chinese supplier claiming there are production problems at EFR (there are not) and trying to push the probably counterfeited RECI tube instead. If you are going to buy your laser tube directly from a Chinese supplier, I would suggest taking the EFR product every time.

4. Correct Laser Power:

Check that the specified power actually reflects the tube you are expecting to arrive, it is easy to check the manufacturer’s websites for information on a particular tube.

5. Fit a Milliammeter:

If your laser machine does not have a milliammeter fitted, it is highly recommended that you fit one yourself. You need to make sure that you do not drive the tube (overdrive) beyond the manufacturers recommended maximum operating current (mA) as this will prematurely age the tube and shorten it’s working life.

- With a Milliammeter fitted you can work out at what percentage power your laser tube operates at its recommended maximum operating current and set this as a limit for all jobs. Many laser software packages will allow you to set this limit within the machine settings.

6. Buy a Laser Power Meter:

I would suggest you buy yourself a low-cost laser power meter and regularly check the output of your laser tube. It’s also a great tool for troubleshooting problems. For the majority of users, it is not worth purchasing a professional laser power meter at several hundred $ £ € as you are looking for an indicative value rather than a precise value. As laser tubes gradually degrade over time, a laser power meter will help you to decide when the time is right to start getting a replacement.

7. Manufactured Date:

Each tube will have a date of manufacture printed on the main label. Ideally, this needs to be as close to the current date as possible, but it’s not unusual for this to be up to two months old. This is important as the manufacturer’s warranty starts from the date of manufacture, not the date of delivery.

8. Maintenance of the Optical Path:

It is important to keep your mirrors clean as well as your lens. On a perfectly aligned and clean optical path, it is not uncommon to lose between 10~12% power, dirty optics will increase this significantly. You should be checking and cleaning your mirrors on a weekly basis, your lens should be checked and cleaned on a daily basis. Running the machine with dirty optics means you will need to either increase the power or decrease the speed to maintain a cut, either way, the laser is working harder or longer than necessary.

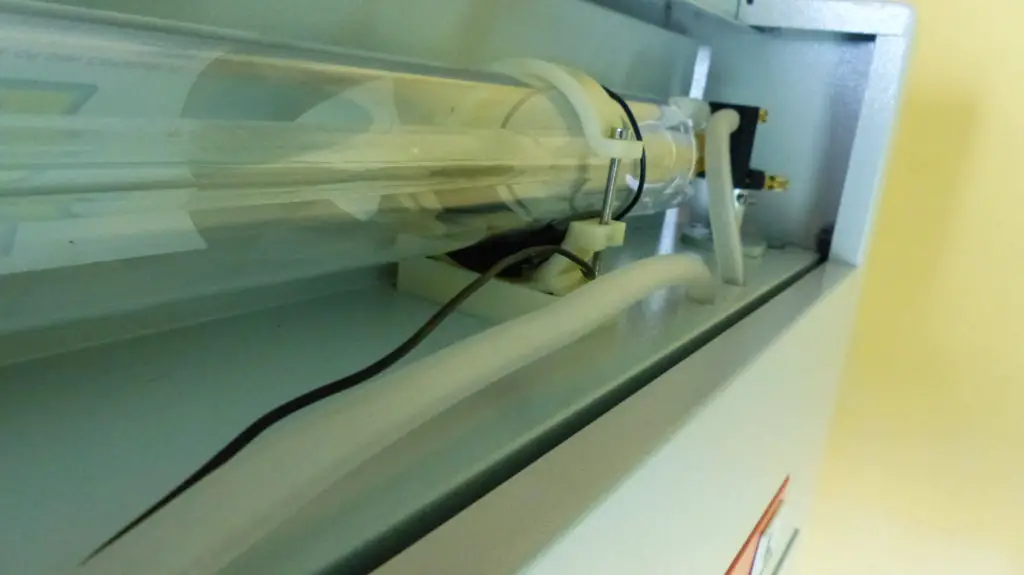

9. Laser cooling system:

If you are able, it is always best to use a fully enclosed cooler or chiller unit. One which measures both temperature and water flow. This unit should not only give an alarm if there is a problem but stop the laser from operating without sufficient cooling. It only takes a couple of minutes to ruin a tube through overheating. Typically a laser tube should be running at between 15C and 25C, as the temperature rises the efficiency of the tube decreases, resulting in a lower power output.

- However, excessive chilling of the water is not usually recommended as the dew point is typically 5C below the ambient temperature. If you chill the water by more than 5C you run the risk of condensation on the glass. Since one end of the tube could be at 15~20KV there is an increased chance of arcing occurring which can damage sensitive electronics if the grounding circuit is not sufficiently robust.

Why Does A Glass Co2 Laser Tube Degrade?

So, why does a glass CO2 laser tube degrade? All glass CO2 laser tubes degrade over time with lifespans ranging from as little as 3 months to 5 or more years. Basically, the CO2 inside the tube breaks down into Carbon Monoxide and Oxygen with use. If you overdrive the tube, it just accelerates this process and reduces the working life.

As the tube degrades, the power output gradually decreases which leads to the user either increasing the power or slowing the cutting speed. Resulting in the tube running harder or longer than necessary. Some tubes contain a catalyst that recombines the Carbon Monoxide and Oxygen, replenishing the lost CO2, but some of the free oxygen can collect on the cathode (the low voltage end of the tube) giving it a yellow tint. This is how manufacturers can determine if the tube has been overdriven and refuse any warranty claim.

A correctly rated laser tube (rated power not max power) will typically have around 10 ~ 15% more power than the actual rating, this additional power allows the manufacturers some headroom when it comes to warranty claims. So it’s not unusual for a 60-watt laser tube for example, to output 66 watts or more.

What Is The Warranty On A Glass CO2 Laser Tube?

So what is the warranty on a glass CO2 laser tube? This varies significantly between manufacturers, the diameter of the tube and the rated laser power. One constant is the warranty starts from the manufactured date, not from when it was first used. Typically the tube fails if it falls below 80% of the rated power within the warranty period.

This is why it is so important to ensure you are being given the rated power of the tube and not the max power. For example, if we look at the EFR CL800 tube; this is 800mm / 31.5″ long, 50mm / 2″ in diameter, has a rated value of 40 watts and a max power of 50 watts. The tube is only classed as a warranty failure if its output power falls below 32 watts in the warranty period of 180 days. So you believe you are buying a 50-watt machine, yet the laser tube could be outputting as little as 33 watts and still be within the manufacturer’s specification. Let’s not forget the 10~12% loss across the optics, leaving you with just 30 watts at the work surface.

This is in no way the fault of the tube manufacturers. They usually specify a rated power and operating current for their tubes. It’s just a marketing ploy of the resellers to use the max power when describing the tubes and an excuse for them to charge you more.

Glowforge Lifespan

While the Glowforge Laser system is a US designed and US built laser system it has a 40 or 45 watt glass DC laser tube which is most likely manufactured in China. Glowforge state it’s a custom tube, but do not give a lot of information about the tube itself.

Without knowing the brand of the tube, it’s a little difficult to estimate it’s working life. However, I have seen reports that it’s not unusual for Glowforge machines to overheat due to insufficient cooling which can have a detrimental effect on the life of the tube. Basically, as the tube heats up it becomes less efficient. Prompting users to start increasing the power, or slowing down the cutting speed. Meaning the laser is working harder for longer under stressful conditions.

I’ve seen reports that the tubes are rated for 1000 or 2000 hours (I assume working hours). If the tubes are decent quality and you don’t overdrive them (see point 5 above) or overheat them, they should last much longer. The tubes appear to be 850mm long and are likely to comply with the stated 40~45 Watt power output.

What Next?

Did you enjoy this post? Why not check out some of our other posts:

Disclaimer

Last updated April 25, 2024

WEBSITE DISCLAIMER

The information provided by n-Deavor Limited, trading as Laseruser.com (“we,” “us” , or “our”) on (the “Site”) is for general informational purposes only. All information on the Site is provided in good faith, however we make no representation or warranty of any kind, express or implied, regarding the accuracy, adequacy, validity, reliability, availability or completeness of any information on the Site.

UNDER NO CIRCUMSTANCE SHALL WE HAVE ANY LIABILITY TO YOU FOR ANY LOSS OR DAMAGE OF ANY KIND INCURRED AS A RESULT OF THE USE OF THE SITE OR RELIANCE ON ANY INFORMATION PROVIDED ON THE SITE. YOUR USE OF THE SITE AND YOUR RELIANCE ON ANY INFORMATION ON THE SITE IS SOLELY AT YOUR OWN RISK.

EXTERNAL LINKS DISCLAIMER

The Site may contain (or you may be sent through the Site) links to other websites or content belonging to or originating from third parties or links to websites and features in banners or other advertising. Such external links are not investigated, monitored, or checked for accuracy, adequacy, validity, reliability, availability or completeness by us.

WE DO NOT WARRANT, ENDORSE, GUARANTEE, OR ASSUME RESPONSIBILITY FOR THE ACCURACY OR RELIABILITY OF ANY INFORMATION OFFERED BY THIRD-PARTY WEBSITES LINKED THROUGH THE SITE OR ANY WEBSITE OR FEATURE LINKED IN ANY BANNER OR OTHER ADVERTISING.

WE WILL NOT BE A PARTY TO OR IN ANY WAY BE RESPONSIBLE FOR MONITORING ANY TRANSACTION BETWEEN YOU AND THIRD-PARTY PROVIDERS OF PRODUCTS OR SERVICES.

AFFILIATES DISCLAIMER

The Site may contain links to affiliate websites, and we receive an affiliate commission for any purchases made by you on the affiliate website using such links. Our affiliates include the following:

- makeCNC who provide Downloadable Patterns, Software, Hardware and other content for Laser Cutters, CNC Routers, Plasma, WaterJets, CNC Milling Machines, and other Robotic Tools. They also provide Pattern Files in PDF format for Scroll Saw Users. They are known for their Friendly and Efficient Customer Service and have a comprehensive back catalogue as well as continually providing New Patterns and Content.

- Cloudray Laser: a world-leading laser parts and solutions provider, has established a whole series of laser product lines, range from CO2 engraving & cutting machine parts, fiber cutting machine parts and laser marking machine parts.