When I first used a CO2 laser cutter, little did I realise just how flexible a tool it could be! Ideal for both industrial and home hobby applications. So what is a CO2 laser cutter?

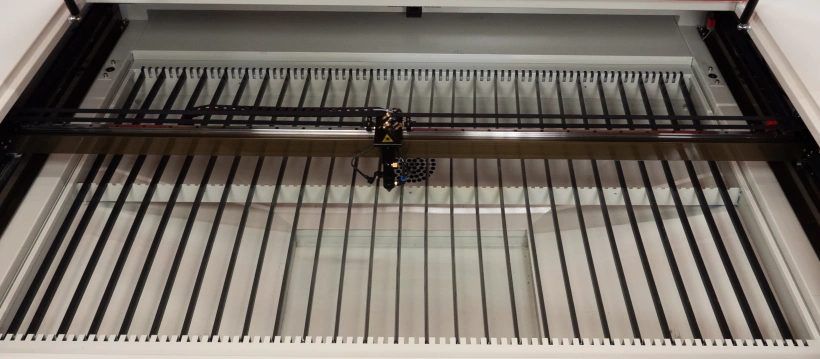

The commonest type of CO2 laser cutter is the Flatbed or CNC style laser cutter. This can be found in a multitude of shapes, sizes and power outputs. It’s a highly versatile tool that uses a laser beam to cut and engrave a variety of substrates.

At lower power outputs (<150W) this is typically restricted to non-metallic materials. Higher powered CO2 lasers can cut metals, although an Oxygen assist may be needed.

However, that’s just the basics, if you continue reading you will discover the key components that make up all but the most basic affordable CO2 laser cutter systems.

CO2 Laser Source

The laser source is the engine of the laser cutter, higher power allows for thicker material to be cut or for thinner materials to be cut quicker. There are two main types of laser sources;

- The water-cooled Glass (DC – Direct Current) laser tube is the main laser source used in the low to mid-range laser cutting and engraving systems with a typical power output range of between 25 ~ 150 watts. They are relatively inexpensive and can be classed as a consumable due to their limited lifespan. Warranties range from 3 ~ 12 months from manufacture but it’s not unusual for the better brands of glass laser tubes to last 18~36 months. Check out this post on how to prolong the life of your laser tube. Quick Tip: RECI, EFR and SPT are three of the better brands of glass CO2 laser tubes. But take care where you purchase the RECI tubes as there are forgeries in the market.

- A Metal (RF – Radio Frequency) laser tube is generally used in the high end / high price industrial laser systems. They have a longer working life than the glass tube, lasting between 4 and 8 years. However, they cost significantly more (10 to 20 times more) than the equivalent glass laser tube. It is generally believed that they offer better engraving performance due to their smaller beam diameter. However, recent testing by Russ Sadler seems to have disproved this belief.

Diode Lasers are also available but are usually supplied in the 405 ~ 1064nm wavelength zone, as opposed to the 10,600nm wavelength of a CO2 laser source. This means they can fall in the visible spectrum (380~700nm) and output a visible colour. These laser diode modules generally range from just 2~7 watts and tend to be used for engraving purposes and limited cutting of very thin substrates. Please Note: because of the differing wavelengths, diode laser modules will have different interactions with materials compared to CO2 lasers and shouldn’t be considered as just low powered CO2 laser sources.

High Voltage Laser Power Supply

The High voltage laser power supply (HV-PSU) is a discrete power supply that runs off the mains voltage supply. It’s main job is to step up the mains voltage (110V / 230V) up to a high enough voltage to run the laser tube. This voltage is typically in the range of 12,000 ~22,000 volts. The higher the power of the laser tube, the higher the voltage that is required. The current supplied by the HV-PSU is very low, typically just 20~35mA.

The HV-PSU can be wired up so that it can be automatically paused / powered off, should there be safety issue such as a door being opened or the water coolant flow being interrupted.

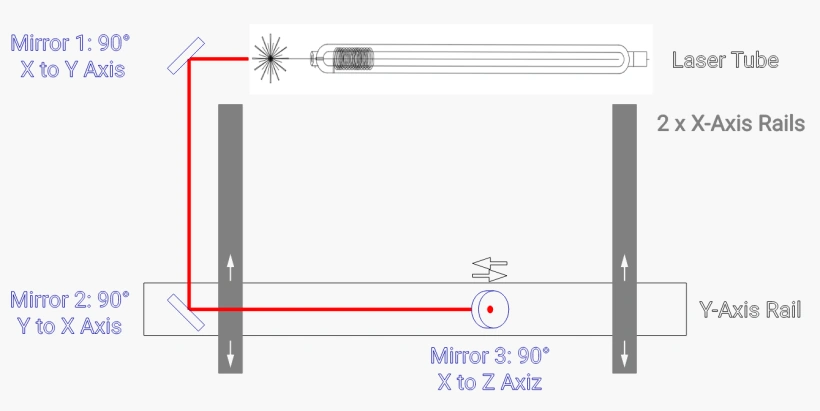

Optical system

Each laser needs an optical system to direct the laser beam from the laser source to the material being cut. This usually consists of three mirrors, each reflecting the laser beam through 90 degrees. Consisting of 180 degrees in the horizontal plane and 90 degrees in the vertical plane. After the third mirror, there is a lens to focus the beam down onto the work surface. The final mirror and lens are generally housed within the laser head assembly.

Depending on the laser cutter, there may be a red diode pointer that gives an approximation as to where the invisible laser beam is likely to hit the material surface.

X-Y axis and cutting bed

The optical system allows us to redirect and focus the beam onto the surface of the material to be cut. The X-Y axis is a gantry system that moves the laser head over a given area. This method of moving the laser head is similar to that used on CNC machines, hence the term “CNC laser cutter”.

The area that the head can move is known as the bed size and can range from as little as 200 x 300mm (8″ x 12″) to 2.5m x 1.5m (98″ x 59″) or even larger. The material is processed in sheet form and is laid flat on a cutting bed. Types of bed available are; metal sheet, slat bed or honeycomb bed. Each has its own benefits and drawbacks.

On many machines, there is also a Z-Axis which allows for the cutting bed to be raised and lowered to accommodate different thicknesses of sheets or objects for cutting or engraving. Machines with a powered Z-axis may also have an auto-focus system allowing for quick and easy set-ups.

Safety system

The safety system is there to keep you safe during normal operation of the laser. It is vitally important that any laser system you purchase has a secure and robust safety system. The laser beam is invisible and can burn or blind you if suitable precautions are not taken. You should be looking for machines that have either Class I or Class II certification, anything else (Class III or Class IV) requires Personal Protection Equipment (PPE) when in use.

Doors to the laser chamber should be interlocked so that if opened when a job is running, it will switch off the laser beam. Any panels that open into the laser chamber should have either key locks or have fittings that require a tool to remove. There should be no direct line of sight to the laser nozzle or the surface of the laser bed when the laser door is closed.

Fume extraction

When laser cutting or engraving materials, fumes or particulates will be given off. Many if not most of these fumes are toxic or carcinogenic. If you have a Class I or Class II laser system, then breathing in fumes from your laser processing offers the greatest risk to your long-term health. (see Safety Systems) Some laser users opt to extract the fumes outside through an open window or doorway. This is not recommended as there is a risk of the fumes blowing back into the room and building up slowly over time.

A fume extraction unit extracts the fumes and particulates from the laser chamber and returns the clean air (99.997%) back into the room. You will just need to periodically change the filters.

Water Chiller

If you are using a CO2 Laser cutter with a glass laser tube (see CO2 Laser Source) you will need some form of water cooler or chiller. In temperate climates, a water cooler should be sufficient for glass tubes up to 80W power output. A water chiller is necessary for laser power outputs of 100W plus.

At the lower end of the scale, you will find that some companies will just provide an aquarium pump and a sealed water container. The best solution is using a dedicated water cooler/chiller that has some over-temperature/flow detection as an over-heated tube will quickly fail.

Quick tips: only use distilled/purified water in your cooling circuit. Do not use de-ionised water or tap water. Also, it is not recommended to use anti-freeze in the water. If there is a risk of freezing, it is best to drain the laser tube. You could also consider some way of heating the water if the temperature falls below 6C.

As with the RECI tubes, be careful where you buy your water coolers/water chillers from as there are a number of forgeries in the market. I would suggest getting the S&A CW3000 Water Cooler for up to 80W laser tubes and the S&A CW5200 Water Chiller for up to 150W laser tubes.

An added bonus when using this type of Water Chiller is that they usually come with an audible alarm should the water flow stop. They can also be wired up in order to automatically pause the laser if the water flow is insufficient.

Air Assist

The air assist system on a laser cutter normally consists of a small, oil-free pump. This pump constantly blows air out through the nozzle on the laser head. It has two main uses;

- The air flow at the nozzle minimises fumes and debris coming in contact with the lens. Meaning the lens stays cleaner for longer.

- The air flow also blows away the smoke at the material surface allowing the laser beam to cut deeper into the material.

Don’t be tempted to use a shop air supply instead of the supplied air pump. A shop air supply runs the risk of contaminating the lens with oil or water. There is also the risk of the shop air supply failing / reservoir running low meaning you may accidently run the laser without air assist. This can cause damage to your lens, or even start a fire as the fumes generated can ignite.

Software for Your CO2 Laser Cutter

There are a wide variety of software packages for CO2 laser cutting machines. Apart from one or two packages, the software supplied is the only software that will work with your laser system. In most cases, the software supplied is just a glorified printer driver with limited graphics capabilities. Most project design work is carried out on true CAD packages with the files imported for printing.

I use RDWorks, Lightburn, Gimp, Inkscape and Paint.net with my laser projects.

So there you are, these are the key components associated with a CO2 laser cutting machine. Hopefully, that has cleared up some of the confusion you may have had.

Frequently Asked Questions

What is a Hobby Laser Cutter?

The hobby laser cutter tends to be a smaller variant of the CO2 laser cutter. Bed sizes are up to around 400 x 600mm / 16″ x 24″ with laser power output between 25 to 60 watts. A 60-watt laser tube should still be able to cut up to 12.5mm / 0.5″ of acrylic. The main limitation with a hobby laser is that it usually has to be able to pass through a standard single doorway. Desktop units tend to be very popular as they generally have at least one dimension smaller than 600mm.

What is a CNC Laser Cutting Machine?

The CNC laser cutting machine is just another name for the CO2 Flatbed laser cutter. It’s a highly versatile tool for cutting and engraving materials that uses a laser head mounted onto a CNC X-Y axis gantry. This gantry is used to move the laser head around the work area, which in turn directs the laser beam onto the work surface.

What is an Industrial Laser Cutter?

The industrial laser cutter typically covers CO2 laser cutting machines with bed sizes larger than 600 x 900mm / 24″ x 36″. Laser power output 80 watts or greater. The very largest machines can cut a full 4′ x 8′ / 1200 x 2400mm sheet of 18mm / 0.7″ thick plywood.

What Next?

Did you enjoy this post? Why not check out some of our other posts:

Disclaimer

Last updated April 25, 2024

WEBSITE DISCLAIMER

The information provided by n-Deavor Limited, trading as Laseruser.com (“we,” “us” , or “our”) on (the “Site”) is for general informational purposes only. All information on the Site is provided in good faith, however we make no representation or warranty of any kind, express or implied, regarding the accuracy, adequacy, validity, reliability, availability or completeness of any information on the Site.

UNDER NO CIRCUMSTANCE SHALL WE HAVE ANY LIABILITY TO YOU FOR ANY LOSS OR DAMAGE OF ANY KIND INCURRED AS A RESULT OF THE USE OF THE SITE OR RELIANCE ON ANY INFORMATION PROVIDED ON THE SITE. YOUR USE OF THE SITE AND YOUR RELIANCE ON ANY INFORMATION ON THE SITE IS SOLELY AT YOUR OWN RISK.

EXTERNAL LINKS DISCLAIMER

The Site may contain (or you may be sent through the Site) links to other websites or content belonging to or originating from third parties or links to websites and features in banners or other advertising. Such external links are not investigated, monitored, or checked for accuracy, adequacy, validity, reliability, availability or completeness by us.

WE DO NOT WARRANT, ENDORSE, GUARANTEE, OR ASSUME RESPONSIBILITY FOR THE ACCURACY OR RELIABILITY OF ANY INFORMATION OFFERED BY THIRD-PARTY WEBSITES LINKED THROUGH THE SITE OR ANY WEBSITE OR FEATURE LINKED IN ANY BANNER OR OTHER ADVERTISING.

WE WILL NOT BE A PARTY TO OR IN ANY WAY BE RESPONSIBLE FOR MONITORING ANY TRANSACTION BETWEEN YOU AND THIRD-PARTY PROVIDERS OF PRODUCTS OR SERVICES.

AFFILIATES DISCLAIMER

The Site may contain links to affiliate websites, and we receive an affiliate commission for any purchases made by you on the affiliate website using such links. Our affiliates include the following:

- makeCNC who provide Downloadable Patterns, Software, Hardware and other content for Laser Cutters, CNC Routers, Plasma, WaterJets, CNC Milling Machines, and other Robotic Tools. They also provide Pattern Files in PDF format for Scroll Saw Users. They are known for their Friendly and Efficient Customer Service and have a comprehensive back catalogue as well as continually providing New Patterns and Content.

- Cloudray Laser: a world-leading laser parts and solutions provider, has established a whole series of laser product lines, range from CO2 engraving & cutting machine parts, fiber cutting machine parts and laser marking machine parts.