The Lightblade Learning Lab with Russ Sadler

The Lightblade Learning Lab is a series of videos that Russ did for Thinklaser Limited based on using the Lightblade 4060 Laser Cutting and Engraving Machine. Thinklasers Lightblade 4060 has a 400 x 600mm bed size and was supplied with a 60W EFR laser tube. In this video, Russ discusses the often underused RDWorks Software Feature of setting the processing order. When used correctly, this RDWorks Software feature can save you both time and money.

Contents

- (This video makes use of the Lightblade Reference Beam design, a device for creating a visible reference beam)

- Doing a complete project (after the design has been done)

- User of layers for different types of cut

- Cutting speeds for small text

- Order of cutting

- Handle/Cut optimise

- Preview/Simulation to check the order of the cutting

- Path optimise (un-checking it)

- Edit Cut Properties to set order of cutting, using groups to simplify this, techniques in selecting objects.

- Saving the file

- Residues caused by cutting acrylic – difficult to clean off honeycomb

- Use of steel bed and magnets

- Airflow

- Cleaning bed with acetone or white vinegar

- Assembling the device that has been made

- Acrylic cement

- Mounting the device on the laser cutter

My thanks go out to Tom at Thinklaser for giving permission to embed these videos on this site. If you are looking for a new laser machine from a quality supplier, then I would suggest you check out their website: www.thinklaser.com.

Video Resource Files For RDWorks Software Feature

There are no resource files associated with this video.

What Software Is Used for Laser Cutting

Two of the most commonly used laser cutting software packages for Chinese manufactured laser cutting and engraving machines are:

- RDWorks: Because it’s based on the popular Ruida Controllers and comes free with laser machines using this controller, and

- LightBurn: Because it’s an excellent laser cutting software package that covers a large variety of laser machines and types of controllers.

External Resource Links For RDWorks Software Feature

There are no more external resource links associated with this video.

Transcript For RDWorks Software Feature

Click the “Show More” button to reveal the transcript, and use your browsers Find function to search for specific sections of interest.

00:15

welcome to another session of lightblade

00:17

learning lab and today we’re going

00:20

to do a complete project we’re going to

00:24

start off with a drawing that I have

00:26

already created in another program and

00:28

as I’ve already mentioned to you this

00:30

program rdworks is not a CAD program

00:34

it’s not a drawing program it’s an

00:35

interface program so you will need to do

00:38

design work elsewhere and then import

00:41

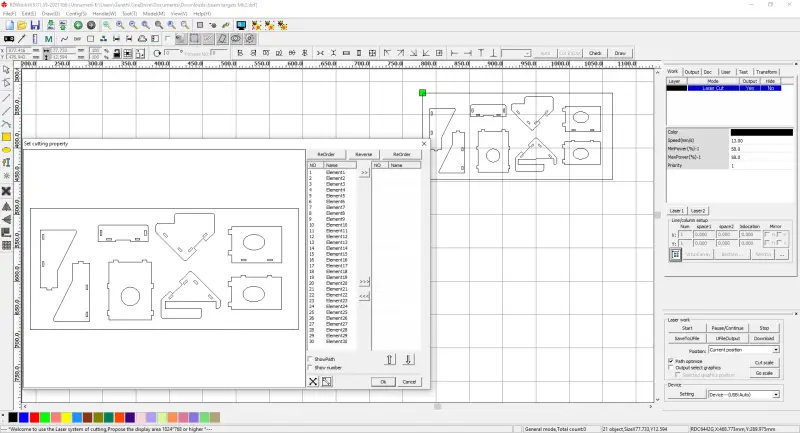

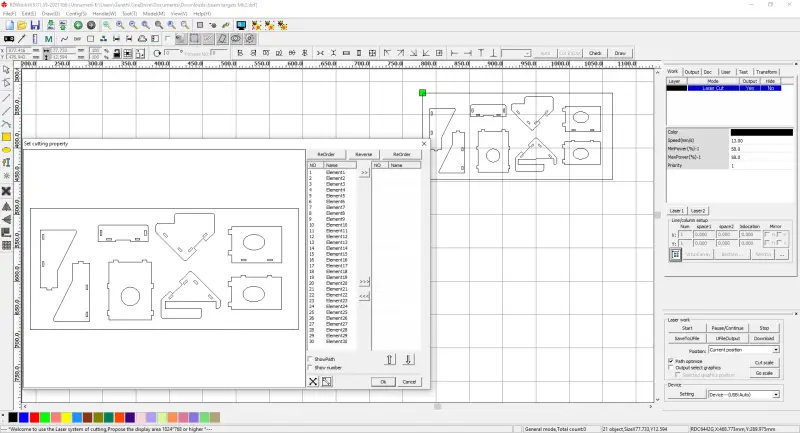

your file now I’ve imported my file here

00:44

series of parts which when we look at

00:48

them you see that they’ve got outside

00:49

shapes they’ve got holes in and we’ve

00:53

got some text now this text was created

00:56

in my cad program and it’s been

00:58

specially created as a single line text

01:01

i purposely haven’t used the sort of

01:05

texts that you would normally think of

01:06

which has got some with to it and some

01:10

character to it

01:11

the reason I’ve done that is because I

01:15

want to keep this session as simple as

01:16

possible and we can actually cut this

01:19

text as opposed to engraving it or

01:21

catching it now engraving is a subject

01:24

all on its own which we will tackle in

01:26

another session so I’m not wanting to

01:29

complicate this session too much because

01:30

we’ve got enough to deal with any way

01:32

we’re going to be cutting the text and

01:35

we’re going to be cutting the outside in

01:37

the shapes but we don’t want the text to

01:40

go right the way through so we’ve got to

01:43

use a different power a different speed

01:46

we’ve got to process the text

01:48

differently to the rest of the items on

01:50

this page to do that we’re going to have

01:53

to put it onto a different layer

01:56

let’s go through how we do that to start

01:58

with first of all we will remove the

Transcript For RDWorks Software Feature (Cont…)

02:00

handles that happen to be defaulted when

02:02

you import it and now we need to mark

02:04

this text now you need to be very

02:07

careful because we’ve got to put a

02:09

little marquee round each piece of it on

02:13

its own so we’ve got lightblade there

02:15

and you’ll notice that is turned rate

02:17

that’s fine that means we’ve captured it

02:19

now we must press the shift key on the

02:22

keyboard without catching any other

02:25

complete object and you’ll see that i

02:28

can start off outside the outside shape

02:31

steer clear of the whole i can go across

02:35

steer clear of that hole on the right

02:37

hand side and steer clear of these that

02:39

all slots at the bottom and I can

02:44

collect that one as well so now i’ve

02:47

added all of these pieces together into

02:50

a little group we haven’t actually

02:51

defined them as a group but they have

02:53

just been marked as a group we will now

02:56

go down to the bottom left-hand corner

02:58

here and we will select any one of these

03:01

colors but let’s just check the select

03:03

the blue layer because we’ve already got

03:04

a black layer on the page

03:05

ok so now our text has become blue and

03:10

you’ll notice up at the top right hand

03:12

corner here we’ve got a blue layer

03:14

that’s been added

03:15

let’s just take a quick look at that

03:17

blue layer by double clicking on the

03:19

blue patch

03:20

ok so how do we go about selecting the

03:23

speed and the power

03:25

well it all comes down to experience in

03:27

a way thinklaser have supplied you with

03:30

a little memory stick with this machine

03:32

now I only suggest that you go in and

03:35

take a look at that memory stick because

03:36

you’ll find data on their referring to

03:39

speeds and feeds for your machine they

03:42

will be typical but they’re at least a

03:45

start

03:46

I’ve got some experience which i will

03:49

call upon and point out to you one or

03:52

two things first of all we’re cutting

03:54

small characters remember the background

03:58

grid on this picture is only five

Transcript For RDWorks Software Feature (Cont…)

04:00

millimetres so that means these

04:02

characters only three millimetres tall

04:04

now

04:06

how fast can the Machine accelerate

04:09

can’t get up to a hundred millimetres a

04:12

second and back down to nothing in three

04:14

millimeters

04:15

I doubt it so the chances are this these

04:20

characters are going to be speed

04:23

controlled by the machine itself not by

04:26

you

04:27

so even if you put 500 millimeters a

04:30

second in there it’s going to make no

04:32

difference told to the speed at which

04:34

these letters are going to be cut so you

04:36

might as well plant something reasonable

04:38

in there hundred millimeters a second is

04:40

still unlikely to be achieved by the

04:42

machine but we don’t want the machine to

04:45

cut all the way through so we need to

04:48

keep the speed fast so that it stays as

04:51

fast as the machine can go the next

04:54

issue is the power we’re going to be

04:55

using three millimeter thick acrylic to

04:58

do this job and even if we were to apply

05:02

maximum power the full 60 watts of my

05:04

machine we would not be able to cut

05:06

through this material at hundred

05:08

millimeters a second

05:10

so therefore it really doesn’t matter

05:13

but what we’re going to do is back the

05:15

power right down to something like

05:17

thirty percent so that we can make sure

05:20

that we scratch the surface rather than

05:23

go deeply in and now we’ll go to the

05:28

black layer which is the cutting liar

05:30

and we’re going to choose some

05:32

parameters for cutting well as i did

05:35

mention to you were using three

05:37

millimeter acrylic on this job from

05:40

experience I would know that cutting

05:42

three millimeter acrylic with probably a

05:44

one-and-a-half inch lens which is a

05:46

quite a powerful cutting lens i would be

05:50

able to probably get up to maybe 20

05:52

maybe even 25 millimeters a second but

05:56

we’re going to be using a

05:57

two-and-a-half-inch maybe 2-inch lens

05:59

which means that its power density is

Transcript For RDWorks Software Feature (Cont…)

06:02

less that’s a completely different

06:03

subject but it does mean to say that i’m

06:05

going to choose a very conservative

06:07

number here and I think 12 probably 12

06:10

is ok maybe even 10 let’s settle with 12

06:14

we can always check it out on the

06:16

machine if we get it wrong we can modify

06:19

the parameters on the machine and power

06:22

well we want the power its maximum now

06:25

you may remember the previous session we

06:27

established that the maximum power I can

06:29

use with my 60 what to buy this machine

06:30

is sixty-seven percent if i run anymore

06:34

than that i will be over driving to tube

06:37

and shortening its life i’m just being a

06:40

good boy and I’m sticking to the 67%

06:42

cutting yes blowing yes output yes job

06:50

done when we cut the first program we

06:53

use the honeycomb paid now i’m going to

06:57

use a slightly different approach this

07:00

time and it means the parts are going to

07:03

physically drop out

07:05

it’s a good way to remember that you

07:09

must ensure that you do your engraving

07:11

or you’re cutting first you must do your

07:16

holes first before you cut your outside

07:20

shapes because once the part has been

07:22

cut it will fall out and you’ve got no

07:25

chance of coming back to cut the holes

07:28

so cut your holes before you cut your

07:31

outside shape so that does mean to say

07:34

that we’ve got to put some logic into

07:36

the way that we order the cuts the

07:40

processes and we talked about how you

07:43

would do that in a previous session and

07:45

we looked at this thing here called

07:48

handle

07:49

and we had something called cut

07:51

optimized if you remember we would have

07:53

order of layer and then we would cut

07:56

inside to outside the order of land

07:58

meant that we could do the blue layer

07:59

first and then we could do the black

Transcript For RDWorks Software Feature (Cont…)

08:02

layer second which is fine but then we

08:07

had a further control within the black

08:09

clay which said that we could cut inside

08:11

to outside on single objects so that

08:15

meant that we would cut all the holes

08:17

before we cut the outside shape all the

08:19

holes before we cut the outside check

08:21

which was perfect that’s exactly what we

08:23

wanted start cut optimized start point

08:27

optimized well yeah you can have it or

08:29

not have it it really isn’t a big issue

08:32

with a small job like this so we could

08:35

say okay let’s see what we’ve just

08:38

created before we go anywhere near the

08:40

machine will go to the previous screen

08:42

we do a simulation and we’ll put that to

08:44

half speed so that we can watch it

08:46

working and sure enough it’s going to

08:49

create the text first weekend no speed

08:53

it up because we don’t sit around here

08:54

too long

08:55

oh it’s doing some outside shapes now

08:57

that’s fine

08:58

now it’s doing some holes first and then

09:01

it’s going to yes it does do the outside

09:03

shape so it’s did behaving itself well

09:05

we could say at that stage

09:07

let’s go to the machine that process

09:10

works most of the time I’ve come across

09:13

quite a few drawings where despite

09:16

setting those features it doesn’t behave

09:19

in the way in which you would predict

09:21

and so consequently I don’t rely on cut

09:25

optimized at all i remove

09:29

these features I on tick every box in

09:33

here and i’m happy to leave that is a

09:35

nothing box and I come down here to the

09:39

right-hand corner and there’s something

09:41

down here called path optimized now that

09:45

could be ticked by default

09:48

make sure you uncheck it ok so now I’ve

09:53

got complete control over how I want

09:56

these pieces cut

09:58

ok so what’s the alternative well

Transcript For RDWorks Software Feature (Cont…)

10:01

there’s a very powerful alternative that

10:03

we can use and that’s a feature up here

10:05

called edit cut property click on that

10:10

and we open up this lovely box let’s

10:13

just move that out the way a minute

10:15

because what we’ve got here is every

10:18

single element on this drawing has got

10:21

its own cutting command and the order in

10:25

which it’s cut is defined by this list

10:28

let’s just take a look for example at

10:32

that outside shape there which are just

10:35

highlighted oh look there it is very

10:38

conveniently on this list its item 20

10:41

what about holes that hole there that’s

10:46

item 19 mm okay so that means that hole

10:50

will be cut before the outside shape but

10:53

hey we don’t want to go around in order

10:55

let’s have a look how many items we’ve

10:57

got on this list we’ve got hundred

10:59

elements on this list that’s a hell of a

11:00

lot of items to rearrange in the order

11:03

in which we want them arranged

11:05

we’re not going to do that we are going

11:07

to use this edit cut property box but

11:10

before we start going in there

11:11

what we’re going to do is we’re going to

11:13

organize yourself into a much smaller

11:17

group of parts and the keyword in that

11:20

sentence was group

11:23

let me just explain we’re going to first

11:26

of all pick up these four holes across

11:28

the bottom here for example and we’ve

11:31

put them into a little selected group

11:34

now we’re going to change them into a

11:36

real group and I keep reinforcing the

11:39

word group because it’s a very powerful

11:41

word so we got here to this command we

11:44

click group so now if we look I can

11:47

click on this one item here and it will

11:50

mark the whole of the group so I’ve got

11:56

to be a little bit smarter with my

11:58

marquee this time because what I’m going

Transcript For RDWorks Software Feature (Cont…)

12:00

to do I’m going to use my market to

12:02

select just four of those external

12:04

shapes but i haven’t selected the

12:08

complete group of holes and so

12:11

consequently the group of holes remains

12:12

black but the outside shapes have gone

12:15

rate i’m not going to press down my

12:17

shift key and it doesn’t matter i could

12:21

for instance come back to hear and I

12:24

could now select

12:27

doesn’t matter them riesel ecting the

12:30

red group but what I haven’t done

12:32

selected the whole of the black group

12:34

and now I’ve managed to capture the

12:36

whole of the group that I wanted which

12:38

is the external shapes along the bottom

12:40

there and I’m going to put those into a

12:42

group now if it had been smart about it

12:46

when I selected these parts to go onto

12:50

this blue layer at the same time I would

12:54

have also put them into a group now I

12:58

didn’t want to preempt this grouping

13:01

technique at that early stage but just

13:05

remember when you’re selecting parts for

13:07

a layer

13:08

it’s very good to group them as well so

13:10

that you’ve already got that job done so

13:14

let’s go back and select my blue parts

13:16

shift key down

13:25

check they’re all rate and we put them

13:28

into a group job done

13:32

ok now I no need to select the holes on

13:35

this part as a group I could start at

13:39

the top here with my marquee and I could

13:42

drag it right towards the bottom here

13:44

and i’ve captured the l of lightblade

13:49

as well so if i leave the l out I should

13:54

just capture the holes which I have done

13:58

shift key down and we’ll capture the

Transcript For RDWorks Software Feature (Cont…)

14:02

rest of the holes so we put all the

14:04

holes on that pattern there as a group

14:06

click group now I don’t have to worry

14:12

about the outside shape at the moment

14:13

because we’re not going to put that into

14:15

a group so now we can put this group of

14:18

holes here into a group and there will

14:24

capture very carefully with a marquee

14:26

not capturing the outside shape the

14:29

holes for that group and the same for

14:34

that group

14:38

I could have captured all of those holes

14:41

and put them into a group not a good

14:45

idea generally in this instance I don’t

14:50

think it would have made any difference

14:51

at all because it’s a very small project

14:55

but in general try and cut your outside

14:59

shape as soon as you cut your holes that

15:03

way you’ll have no miss registration

15:05

possibility between the outside shape

15:08

and your holes if i move if i do this

15:13

pattern here and then move off and do

15:14

all sorts of other things

15:16

there’s always a risk a very low risk

15:19

but there’s always a risk that by the

15:21

time I come back to cut this shape the

15:24

holes may well have moved very slightly

15:26

most of the time it doesn’t matter but

15:28

in certain key jobs like this one it

15:31

would matter so as a general practice i

15:34

would advise cut the holes first and

15:36

immediately cut your outside shape right

15:40

now that we’ve done a grouping process

15:41

let’s go and have a look see what effect

15:43

its had on our cut list edit cut

15:46

property

15:47

well there we go from a hundred elements

15:50

we now down to 11 elements that’s a much

15:53

more manageable list for us to edit so

15:56

we will start off by clicking on the

15:59

part that we want to run first which are

Transcript For RDWorks Software Feature (Cont…)

16:01

the holes and you’ll notice they have

16:03

highlighted and we can see in this list

16:07

that element number five we don’t need

16:09

to click on that because it’s already

16:10

highlighted for us we can just go to the

16:12

double arrows at the top of the list and

16:14

do click and it will transfer that item

16:17

to a new list as number one in the list

16:20

and then we’ll do the outside shape

16:24

click

16:26

then we’ll do the text here click then

16:30

we’ll do the holes click outside shape

16:36

make sure you highlight the outside

16:39

shape then we’ll get the whole highlight

16:41

outside shape missed it outside shape

16:49

holes

16:55

actually shape

17:00

holds

17:04

actually shape

17:07

and there we go there’s our well ordered

17:09

list so we can now say okay and to be

17:16

honest once you organize that list like

17:19

that you don’t ever need to go up here

17:23

to preview again because you could be

17:26

totally confident that the machine will

17:28

do what you want it to do

17:30

we’ll just go and have a look to prove

17:32

the point of making the simulation will

17:34

be perfect

17:35

trust me holds outside shapes along the

17:40

bottom text next holes next outside

17:44

shape inside holes outside shape and an

17:52

outside shape at the moment we’re still

17:54

programming remotely we’re not on the

17:56

machine if we’re on the machine we would

17:59

be doing a download but because we’re

Transcript For RDWorks Software Feature (Cont…)

18:02

not on the machine we’re saving the file

18:04

to a memory stick

18:05

so we need to go to save to you file i

18:10

would advise you as a general practice

18:12

go here first file save as

18:18

now if you’ve started to on a very

18:20

complicated program i was just that you

18:23

go and save as at a very early stage and

18:27

we’ll save this as beam ref now this get

18:32

saved as a a dot rld file which means

18:35

that it is readable by rdworks again

18:38

and again whereas when we go to save to

18:42

you file what it does it creates a

18:45

machine code program which you cannot

18:48

open and you cannot read so don’t try

18:52

and open in rd file in here because you

18:55

won’t succeed

18:57

although rdworks is fairly bulletproof

19:01

there are times when you can get it to

19:03

crash

19:05

and if your part way through your

19:06

programming and it may be a big program

19:09

and the program crisis you are going to

19:12

be a little bit frustrated now you

19:17

notice how just zoomed out there with my

19:20

scroll if we took take a look up at the

19:22

top left hand corner we should find that

19:25

this is the eight dot 0 1 dot 18 thats

19:29

issue 18 there have been lots of issues

19:31

of this program and something which has

19:36

been fixed and hasn’t been fixed and if

19:39

I scroll down far enough

19:41

completely Oh

19:48

I can’t scroll back again program has

19:51

crashed close the program that’s the

19:53

only choice we’ve got so if we haven’t

19:55

saved we’re going to be a bit upset

19:58

fortunately we saved it before we

Transcript For RDWorks Software Feature (Cont…)

20:01

crashed it so i can now open this file

20:04

as beam reference this Honey Can bed

20:07

it’s it’s better than I expected it to

20:10

be but it’s still got some problems

20:12

which I foresee for the future and I

20:15

don’t want to make this bait sticky one

20:21

of the problems with acrylic is it

20:23

changed to produce a watery residue a

20:27

bit like steam that condenses into a

20:30

sticky goo around the place it can go

20:33

into your filters it can go into here

20:36

and it would make this sticky which

20:39

further attracts dust i use a still play

20:45

now the steel plate is got several

20:47

advantages first water on here look I

20:50

can I can stick to magnets so we can

20:53

support put the support right on the

20:55

corner so they’re not likely to be cat

20:57

for we don’t have to worry about it and

21:00

we’ll just check where that one goes in

21:03

relation to the program but i think it’s

21:06

going to be clear of the program and as

21:08

it’s working i would explain why i’ve

21:10

done that so it’s about it’s about 10 or

21:13

12 millimeters clearance underneath

21:14

there now i’m going to make sure that

21:19

the magnets are sitting in the corner

21:21

somewhere away from the work itself in

21:24

other words where I’m going to cut the

21:26

program but it’s

21:29

I think I put one in the middle there

21:37

yep that’s that’s quite nicely supported

21:40

their first task autofocus so we will

21:46

drive onto the job

21:49

check that wilfully up with her head

21:59

okay so it’s not making the autofocus

Transcript For RDWorks Software Feature (Cont…)

22:01

sensor

22:07

what that means is we’ve got to gently

22:12

drop the probe down and so it just about

22:16

but not quite touches the surface which

22:19

is lifting attach it and lift it off and

22:22

now we press autofocus again

22:45

right now the other thing that I’m going

22:46

to do is to ask you to look carefully at

22:49

the flow of the smoke that’s coming out

22:53

underneath the fumes and because what

22:56

I’m going to do at the moment i’m

22:58

running this machine with the lead open

23:00

where I’m going to do is to close the

23:03

lid and we’re going to look at the

23:04

difference between the air flow with the

23:07

lead open and the lead closed i’m going

23:10

to turn the extraction system on the

23:13

program

23:20

you can see the smoke puffing away

23:26

and redrawn nicely at the back of the

23:29

machine but

23:31

I suspect that’s going to get a lot

23:32

better

23:37

I think it proves the point the FBI was

23:39

actually better with the lid open

23:41

it’s just the airflow is being strangled

23:45

by the holes in the league

23:49

with the lid closed the fumes were

23:51

egging up in the case not waiting up

23:54

here

Transcript For RDWorks Software Feature (Cont…)

24:00

but if you notice the film is underneath

24:20

ok so there’s the job cut quite often

24:22

when you’re cutting acrylic you will get

24:24

a watery residue left on the surface

24:28

here and it’s very sticky if there is

24:33

just hate it there

24:36

although on this occasion I’ve not

24:40

created the sticky it’s a little bit but

24:42

i haven’t created the sticky goo that

24:45

often happens when you’re cutting

24:46

acrylic but what I’d normally do is I

24:50

would use then acetone 20 yes it’s

24:55

definitely sticky and how to fill this

24:57

dragging i would put use it with use

25:00

acetone to clean them off but recently

25:02

somebody said to me why use a dangerous

25:04

chemical when all you really need is

25:06

white vinegar and that does a superb job

25:09

my argument really is if it’s condensing

25:13

on here and I can wipe it away it’s not

25:16

going down into the machine or into the

25:18

extraction system now there is one more

25:20

obvious advantage of housekeeping

25:22

advantage over using the honeycomb bait

25:24

then there is this

25:31

all our pieces now with the film

25:34

stripped off and we’re going to need as

25:39

an assortment of parts which I would

25:41

describe as we go along but there will

25:43

also be a listing of this and probably

25:46

on the thing place of website now the

25:49

one thing that won’t be fined is this

25:53

now I defy anybody to say they haven’t

25:56

got at least half a dozen of these click

25:58

pens around in there draw that either

Transcript For RDWorks Software Feature (Cont…)

26:00

don’t work or that they don’t need well

26:02

now you’ve got a use for them because

26:04

inside here is a valuable resource and

26:10

there it is

26:10

we’ll need two of those Springs if you

26:18

can find a matching pair

26:19

briggen if they don’t match don’t get

26:22

too upset

26:24

ok now the first item we’re going to

26:26

pick up as the this one with all that

26:29

because in the middle and if you look

26:32

carefully you’ll see that around about

26:33

ten o’clock here we’ve got a little hole

26:36

3 millimeter hold now we need to pick up

26:40

this piece as well and again you’ll find

26:43

that you cannot put this one on and

26:46

match the holes up unless you put on the

26:48

right way so that sits in front of their

26:51

want that then you turn them over one of

26:58

those and then two of these

27:00

ok now the moment I’ve got my hole down

27:02

here at about five o’clock or six

27:05

o’clock to slide this place off for a

27:07

moment and we’re going to put the one

27:10

with the hexagon in front of the one

27:12

with the Holy and then we’re going to

27:17

put those tons into that hole there so

27:22

the hexagon is facing this center hole

27:26

and then we’re going to take this piece

27:28

i’m going to drop it over

27:35

they’re like that and that should sit in

27:37

there and that should all look in there

27:40

nicely now like a little corner

27:42

reference angle now we’re going to do

27:50

exactly the opposite over this corner

27:51

here this little piece here will drop

27:54

over and cross lap with that one and

27:58

plug into the matchup a hole in here

Transcript For RDWorks Software Feature (Cont…)

28:00

with the whole in here and we’re going

28:03

to slip this one over the top

28:06

technically it doesn’t need glowing at

28:09

all because everything is nice and snug

28:12

in there but i would advise you to glue

28:16

it going to use this bond right cement

28:18

again which technically as I keep

28:20

telling you should be acrylic cement

28:22

this is petg well cement which will

28:26

perform satisfactory on a critic who

28:28

drops to the bottom of that ball that’s

28:30

enough to do the job I would suggest

28:32

whenever you’re using this stuff you do

28:33

it over or on a piece of kitchen towel

28:37

because it is quite aggressive two

28:40

surfaces and also you don’t really want

28:43

running anywhere so it does if there’s

28:45

any excess go through to the other side

28:46

it will automatically soak up in here

28:48

now the light may or may not be right

28:51

for you to see this when i pop that in

28:53

there and tip it up i should be able to

28:57

get a little bead to run down there and

29:00

i’ll get a little bit to run down there

29:02

as well and one down here

29:11

one down here now feel is already run

29:17

through the back onto my fingers so just

29:19

like the back off the next place

29:22

involves these llamas they look like

29:24

llamas or reindeer is if you look

29:28

carefully you’ll see that three of them

29:31

have got noses and one of them doesn’t

29:36

so the one that doesn’t have a nose on

29:40

it

29:41

topic 2 aside for a minute now if you

29:44

can read that text then right about here

29:47

at about eight o’clock time you’ll see

29:48

there’s a small hole

29:52

it should be a matching hole in the disk

29:55

so you should be able to line them up

29:58

but the reason why I’m asking you to do

Transcript For RDWorks Software Feature (Cont…)

30:01

this is because these have got to go on

30:04

the back of this so we turn it over and

30:10

one of those with the nose on going to

30:12

very carefully try to get it through

30:16

both thicknesses that could be quite

30:22

stiff we’re not rely on anything other

30:25

than friction to hold this together so

30:28

it is not if it’s not a snug fit then

30:32

realistically we’ve got to go back and

30:35

we’ve got to remake these holes here to

30:39

make this snow fit now that’s a

30:42

completely different design exercise

30:44

which I need to go through with you at

30:45

some future date how you’re going to

30:47

design parts to fit because it depends

30:51

on the lanes that you’re using and

30:53

various other things about the material

30:55

that you using the 50 you’re going to

30:57

get now what we need is this little

31:01

thing here now this is only a few paints

31:04

off of ebay and it is in fact a laser

31:08

diode so pretty came through the whole

31:11

to start with and then very gently

31:15

because these cables here are delicate

31:18

that should

31:20

sit snugly between the reindeers the

31:28

nose of the reindeer should fit in a

31:30

slot that’s round here and that will

31:33

lock that in place so this needs to be

31:35

pushed in

31:35

make sure you’ve got the nose or the

31:37

reindeers pushed in

31:39

then we need the reindeer or the llama

31:41

without the nose on as the last one now

31:45

before you put that one in if you take a

31:48

look your savings it was circuit board

31:50

on there make sure that that circuit

31:51

board is not projecting anywhere to get

31:53

in the way of the llamas that should be

31:55

sitting between somewhere between the

31:58

lovers if these little pigs sufficiently

Transcript For RDWorks Software Feature (Cont…)

32:01

stuck in these holes they should be

32:04

completely solid in here and knock

32:06

around at all

32:07

now if you really need to you can glue

32:11

the bottom there and you can even put a

32:13

blob of glue down against the data gets

32:17

the laser diode as well the point is the

32:21

diode must not move

32:23

it’s got to be rock solid now in normal

32:27

engineering circumstances I would

32:30

suggest you drove her out where we put a

32:32

hole through there and I would

32:33

physically be tapping putting attack

32:35

through there but understand that

32:37

probably most of you guys might not have

32:38

tapping facilities and what I’ve done

32:41

I’ve arranged to put a nut in their

32:44

in-state for attack toll

32:47

ok so we put a nut in there and we put

32:50

one of these long one each plastic

32:53

screws through there

33:00

but make sure that it doesn’t stick out

33:02

about this surface with the two screws

33:05

at the top and the lightblade

33:09

description sitting the right way round

33:12

you will see that this little piece of

33:16

the back here if you look carefully

33:20

you’ll see that is greatest

33:22

it’s curved and it sits in these little

33:27

slots here and if you rock it around

33:32

you’ll find that it rocks around very

33:39

easily into planes now the idea of that

33:42

mechanism is at the front face of the

33:47

LED always remains in the same position

33:51

in space is the back end of the LED

33:54

which is swinging around not the front

33:57

and now the next part of the assembly I

33:59

need you to make sure they go together

34:00

like this with the holes lining up with

Transcript For RDWorks Software Feature (Cont…)

34:03

each other and before you start using

34:07

these springs which we cut down so

34:11

they’re probably 15 about 15 mil longer

34:14

springs but then I want you to get hold

34:16

of the end of the spring where you cut

34:18

it and physically just bend it out like

34:26

that

34:27

can you see that so that sticks out

34:29

about three millimeters

34:31

now the reason you’re doing that is

34:34

because the spring will actually sit

34:36

down and jam inside the hole and we

34:40

don’t want that to happen at three

34:41

o’clock we’re gonna go any three screw

34:43

through and then we’re going to put the

34:45

spring on with its tail against the

34:48

plastic and then you’re going to put the

34:51

nut on as you can see the spring is

34:53

about the same length as the screw

34:56

itself so that’s an ideal guy just how

Transcript For RDWorks Software Feature (Cont…)

35:00

long the spring has got to be cut down

35:01

and then we need to wind and not on so

35:04

that it’s just flush with the screw the

35:07

one that’s at six o’clock we need to do

35:09

the same tingly

35:10

ok now if you

35:11

grab hold of these two holes opposite

35:14

the springs you should find the whole

35:18

thing will flex up and down and you’ve

35:22

got a nice little sort of fancy

35:24

compression flexi sisters your other 2m4

35:28

nuts and put those behind there there is

35:33

a there is a cavity behind there to take

35:35

the nut house in the cavity and put your

35:39

screw through from the front

35:40

ok so hopefully we’ve now got a nice

35:43

gift nice little game board led pointer

35:48

now I’m just gonna go with my soul

35:50

during iron and attached some extension

35:52

leads to these here we’ve got a cheap

35:56

battery box with a couple of AAA

35:58

batteries in it with a switch on it so

36:02

it’s a nice convenient portable tool you

Transcript For RDWorks Software Feature (Cont…)

36:06

could buy these as a fireball diode and

36:10

you could probably hook it up to your US

36:13

based system somewhere but i thought

36:16

that the 3 volt version would work

36:19

better with a battery box but here i

36:22

have about a meter and a half away from

36:27

the war we’re projecting this onto and

36:29

I’ve got a spot there is about probably

36:32

four millimeters diameter as i close in

36:39

to what six inches it might have dropped

36:43

three millimeters it’s not changing

36:45

significantly the flare pattern or the

36:48

interference pattern around the outside

36:49

is changing but the actual dot itself is

36:52

not changing

36:53

let’s see where it goes and what we’re

36:55

going to be able to do with it right

36:59

here is going to be able to drop their

37:00

in there like that make sure i’m not

37:03

support back into the slots know that

37:06

should be flat back of the front face of

37:08

the water jacket

37:11

no we can turn it on

37:14

and you may remember in one of our

37:18

earlier sessions now that we made this

37:20

is our first project and this is a

37:24

little target holder if we open up the

37:26

side door of the Machine a little target

37:28

holder sits on top of that mirror plate

37:33

there make sure it sits tight against

37:35

the plate at the bottom so they’re

37:37

sitting back nice and flat is the

37:41

beamline up on center one way and now

37:45

i’m adjusting screws the line-up on

37:46

centre the other way now move that one

37:51

out of the way or we can leave it in

37:52

place and just remove the target because

37:55

the beam is designed to pass through

37:57

there so we could leave that in place

37:58

like that and here we have the other

Transcript For RDWorks Software Feature (Cont…)

38:02

target holder that you made and that

38:04

fits snugly over this mirror number

38:08

three fit snugly back against it we can

38:14

hit the target in the top there and

38:24

we can see how we lined up on that one

38:26

so that immediately tells me that

38:30

there’s some sort of problem with the

38:32

alignment of the mirrors on this machine

38:33

which I’m gonna have to look at sooner

38:37

rather than later so maybe that will be

38:40

the next session now that we’ve got this

38:42

tool i could tweak it up coming to the

38:47

right place because the fact that i’ve

38:52

said it correct on mirror number two so

38:55

that’s now more or less correct mirror

38:57

number three at the extremity of the

38:59

beam path

39:00

let’s just go back and check what it is

39:04

at mirror number two

39:06

well that’s what mirror number two looks

39:09

like it’s a bit high but it’s still

39:16

hitting the mirror because it’s still

39:19

within one target ring and we’ll talk

39:26

about what those rings mean in the next

39:29

session

39:30

thank you very much for your time again

39:32

i hope this has been an interesting one

39:34

I think it’s going to be even more

39:35

interesting in the next session actually

Transcript For RDWorks Software Feature

What Next?

Did you enjoy this post? Why not check out some of our other posts:

Disclaimer

Last updated August 26, 2021

WEBSITE DISCLAIMER

The information provided by n-Deavor Limited, trading as Laseruser.com (“we,” “us” , or “our”) on (the “Site”) is for general informational purposes only. All information on the Site is provided in good faith, however we make no representation or warranty of any kind, express or implied, regarding the accuracy, adequacy, validity, reliability, availability or completeness of any information on the Site.

UNDER NO CIRCUMSTANCE SHALL WE HAVE ANY LIABILITY TO YOU FOR ANY LOSS OR DAMAGE OF ANY KIND INCURRED AS A RESULT OF THE USE OF THE SITE OR RELIANCE ON ANY INFORMATION PROVIDED ON THE SITE. YOUR USE OF THE SITE AND YOUR RELIANCE ON ANY INFORMATION ON THE SITE IS SOLELY AT YOUR OWN RISK.

EXTERNAL LINKS DISCLAIMER

The Site may contain (or you may be sent through the Site) links to other websites or content belonging to or originating from third parties or links to websites and features in banners or other advertising. Such external links are not investigated, monitored, or checked for accuracy, adequacy, validity, reliability, availability or completeness by us.

WE DO NOT WARRANT, ENDORSE, GUARANTEE, OR ASSUME RESPONSIBILITY FOR THE ACCURACY OR RELIABILITY OF ANY INFORMATION OFFERED BY THIRD-PARTY WEBSITES LINKED THROUGH THE SITE OR ANY WEBSITE OR FEATURE LINKED IN ANY BANNER OR OTHER ADVERTISING.

WE WILL NOT BE A PARTY TO OR IN ANY WAY BE RESPONSIBLE FOR MONITORING ANY TRANSACTION BETWEEN YOU AND THIRD-PARTY PROVIDERS OF PRODUCTS OR SERVICES.

AFFILIATES DISCLAIMER

The Site may contain links to affiliate websites, and we receive an affiliate commission for any purchases made by you on the affiliate website using such links. Our affiliates include the following:

- makeCNC who provide Downloadable Patterns, Software, Hardware and other content for Laser Cutters, CNC Routers, Plasma, WaterJets, CNC Milling Machines, and other Robotic Tools. They also provide Pattern Files in PDF format for Scroll Saw Users. They are known for their Friendly and Efficient Customer Service and have a comprehensive back catalogue as well as continually providing New Patterns and Content.

- Cloudray Laser: a world-leading laser parts and solutions provider, has established a whole series of laser product lines, range from CO2 engraving & cutting machine parts, fiber cutting machine parts and laser marking machine parts.